Popular Woodworking 2004-06 № 141, страница 22

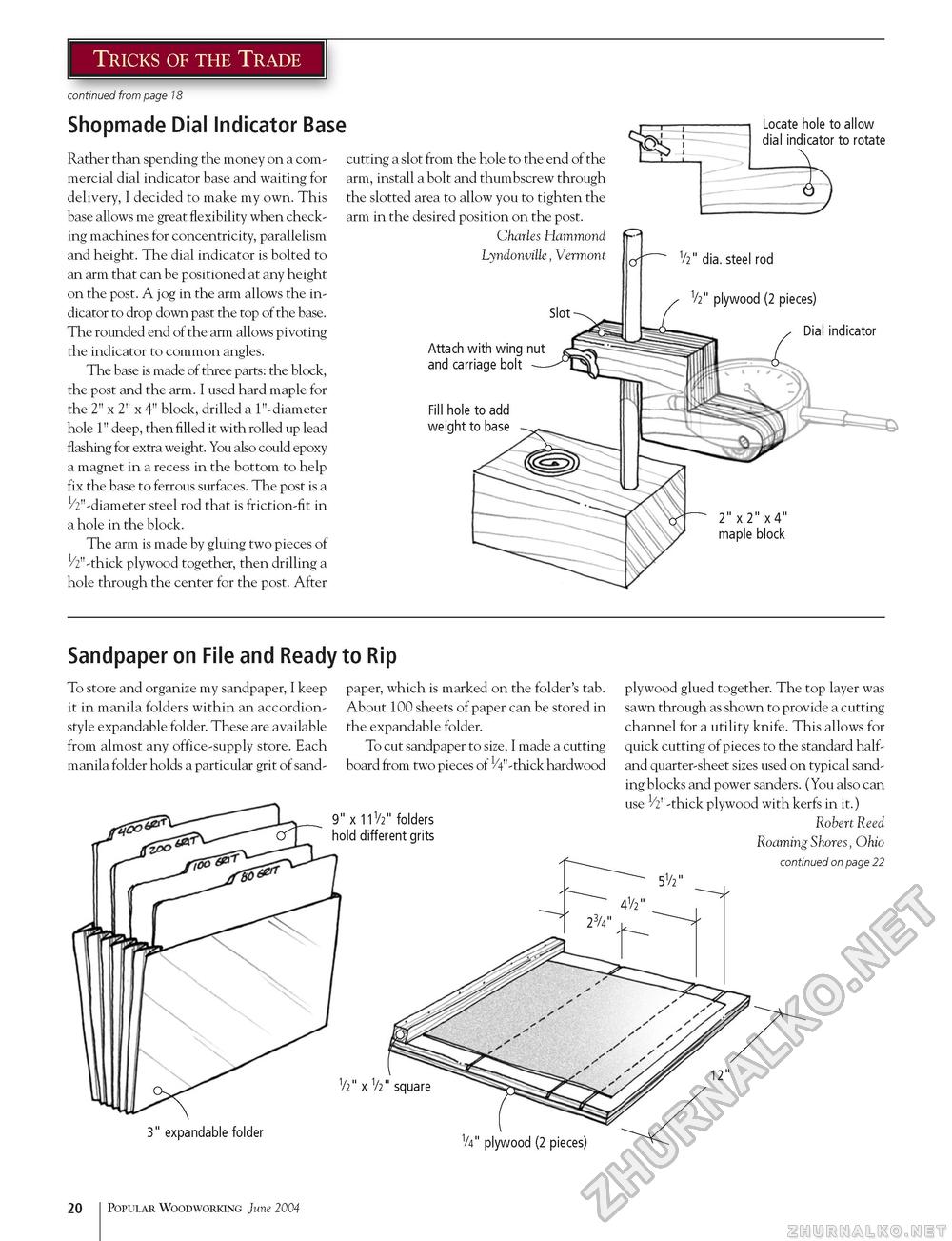

Shopmade Dial Indicator Base Rather than spending the money on a commercial dial indicator base and waiting for delivery, I decided to make my own. This base allows me great flexibility when checking machines for concentricity, parallelism and height. The dial indicator is bolted to an arm that can be positioned at any height on the post. A jog in the arm allows the indicator to drop down past the top of the base. The rounded end of the arm allows pivoting the indicator to common angles. The base is made of three parts: the block, the post and the arm. I used hard maple for the 2" x 2" x 4" block, drilled a 1"-diameter hole 1" deep, then filled it with rolled up lead flashing for extra weight. You also could epoxy a magnet in a recess in the bottom to help fix the base to ferrous surfaces. The post is a ^"-diameter steel rod that is friction-fit in a hole in the block. The arm is made by gluing two pieces of 1/2"-thick plywood together, then drilling a hole through the center for the post. After cutting a slot from the hole to the end of the arm, install a bolt and thumbscrew through the slotted area to allow you to tighten the arm in the desired position on the post. Charles Hammond Lyndom'ille, Vermont Attach with wing nut and carriage bolt Locate hole to allow dial indicator to rotate 1/2" dia. steel rod 1/2" plywood (2 pieces) Dial indicator Fill hole to add weight to base 2" x 2" x 4" maple block Sandpaper on File and Ready to Rip To store and organize my sandpaper, I keep it in manila folders within an accordion-style expandable folder. These are available from almost any office-supply store. Each manila folder holds a particular grit of sand paper, which is marked on the folder's tab. About 100 sheets of paper can be stored in the expandable folder. To cut sandpaper to size, I made a cutting board from two pieces of 1/4"-thick hardwood 9" x IIV2" folders hold different grits

plywood glued together. The top layer was sawn through as shown to provide a cutting channel for a utility knife. This allows for quick cutting of pieces to the standard half-and quarter-sheet sizes used on typical sanding blocks and power sanders. (You also can use 1/2"-thick plywood with kerfs in it.) Robert Reed Roaming Shores, Ohio continued on page 22 5V2" V2" x V2" square 3" expandable folder V4" plywood (2 pieces) 20 Popular Woodworking June 2004 |