Popular Woodworking 2004-06 № 141, страница 35

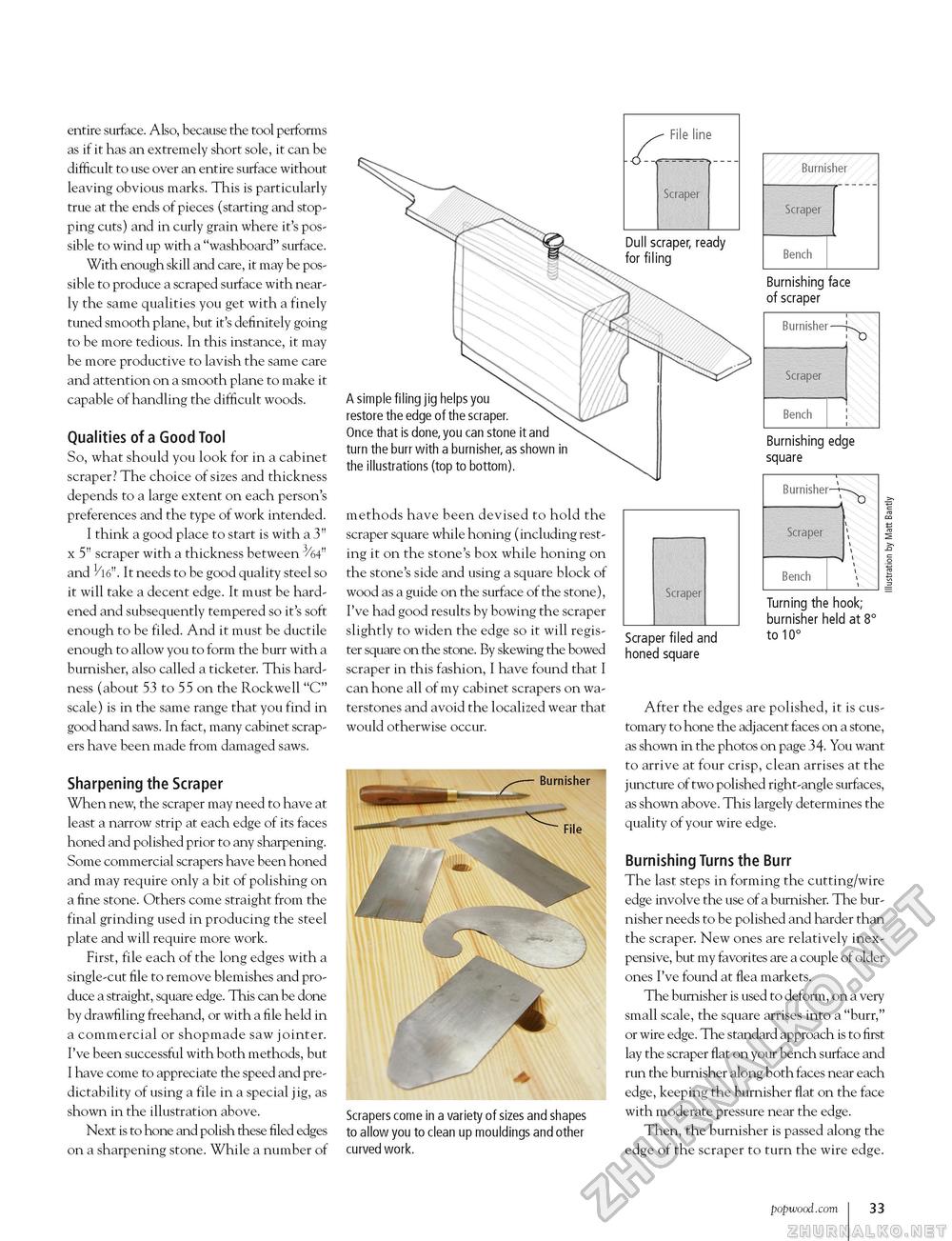

entire surface. Also, because the tool performs as if it has an extremely short sole, it can be difficult to use over an entire surface without leaving obvious marks. This is particularly true at the ends of pieces (starting and stopping cuts) and in curly grain where it's possible to wind up with a "washboard" surface. With enough skill and care, it may be possible to produce a scraped surface with nearly the same qualities you get with a finely tuned smooth plane, but it's definitely going to be more tedious. In this instance, it may be more productive to lavish the same care and attention on a smooth plane to make it capable of handling the difficult woods. Qualities of a Good Tool So, what should you look for in a cabinet scraper? The choice of sizes and thickness depends to a large extent on each person's preferences and the type of work intended. I think a good place to start is with a 3" x 5" scraper with a thickness between 3/64" and 1/16". It needs to be good quality steel so it will take a decent edge. It must be hardened and subsequently tempered so it's soft enough to be filed. And it must be ductile enough to allow you to form the burr with a burnisher, also called a ticketer. This hardness (about 53 to 55 on the Rockwell "C" scale) is in the same range that you find in good hand saws. In fact, many cabinet scrapers have been made from damaged saws. Sharpening the Scraper When new, the scraper may need to have at least a narrow strip at each edge of its faces honed and polished prior to any sharpening. Some commercial scrapers have been honed and may require only a bit of polishing on a fine stone. Others come straight from the final grinding used in producing the steel plate and will require more work. First, file each of the long edges with a single-cut file to remove blemishes and produce a straight, square edge. This can be done by drawfiling freehand, or with a file held in a commercial or shopmade saw jointer. I've been successful with both methods, but I have come to appreciate the speed and predictability of using a file in a special jig, as shown in the illustration above. Next is to hone and polish these filed edges on a sharpening stone. While a number of

Dull scraper, ready for filing Dull scraper, ready for filing A simple filing jig helps you restore the edge of the scraper. Once that is done, you can stone it and turn the burr with a burnisher, as shown in the illustrations (top to bottom). methods have been devised to hold the scraper square while honing (including resting it on the stone's box while honing on the stone's side and using a square block of wood as a guide on the surface of the stone), I've had good results by bowing the scraper slightly to widen the edge so it will register square on the stone. By skewing the bowed Scraper Scraper filed and honed square

Burnisher Burnisher Scraper Bench Burnishing edge square

Turning the hook; burnisher held at 8 to 10° Turning the hook; burnisher held at 8 to 10° scraper in this fashion, I have found that I can hone all of my cabinet scrapers on wa-terstones and avoid the localized wear that would otherwise occur. Scrapers come in a variety of sizes and shapes to allow you to clean up mouldings and other curved work. After the edges are polished, it is customary to hone the adjacent faces on a stone, as shown in the photos on page 34. You want to arrive at four crisp, clean arrises at the juncture of two polished right-angle surfaces, as shown above. This largely determines the quality of your wire edge. Burnishing Turns the Burr The last steps in forming the cutting/wire edge involve the use of a burnisher. The burnisher needs to be polished and harder than the scraper. New ones are relatively inexpensive, but my favorites are a couple of older ones I've found at flea markets. The burnisher is used to deform, on a very small scale, the square arrises into a "burr," or wire edge. The standard approach is to first lay the scraper flat on your bench surface and run the burnisher along both faces near each edge, keeping the burnisher flat on the face with moderate pressure near the edge. Then, the burnisher is passed along the edge of the scraper to turn the wire edge. popwood.com 33 |

|||||||||||||||||||||||||||||