Popular Woodworking 2004-10 № 143, страница 44

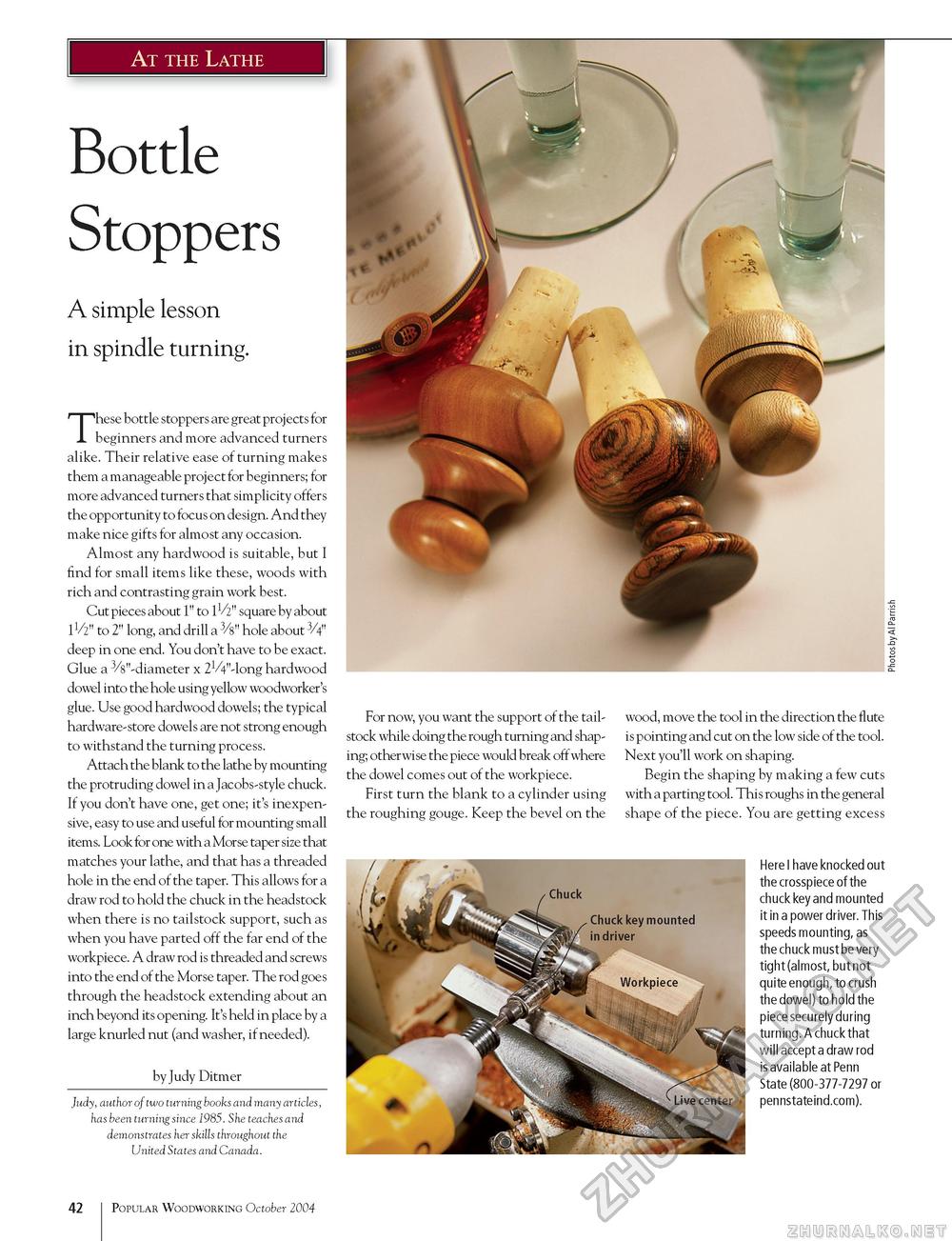

At the Lathe Bottle Stoppers A simple lesson in spindle turning. These bottle stoppers are great projects for beginners and more advanced turners alike. Their relative ease of turning makes them a manageable project for beginners; for more advanced turners that simplicity offers the opportunity to focus on design. And they make nice gifts for almost any occasion. Almost any hardwood is suitable, but I find for small items like these, woods with rich and contrasting grain work best. Cut pieces about 1" to IV2" square by about lVi" to 2" long, and drill a 3/s" hole about 3/4" deep in one end. You don't have to be exact. Glue a 3/8"-diameter x 21/4"-long hardwood dowel into the hole using yellow woodworker's glue. Use good hardwood dowels; the typical hardware-store dowels are not strong enough to withstand the turning process. Attach the blank to the lathe by mounting the protruding dowel in a Jacobs-style chuck. If you don't have one, get one; it's inexpensive, easy to use and useful for mounting small items. Look for one with a Morse taper size that matches your lathe, and that has a threaded hole in the end of the taper. This allows for a draw rod to hold the chuck in the headstock when there is no tailstock support, such as when you have parted off the far end of the workpiece. A draw rod is threaded and screws into the end of the Morse taper. The rod goes through the headstock extending about an inch beyond its opening. It's held in place by a large knurled nut (and washer, if needed). by Judy Ditmer Judy, author of two turning books and many articles, has been turning since 1985. She teaches and demonstrates her skills throughout the United States and Canada. For now, you want the support of the tail-stock while doing the rough turning and shaping; otherwise the piece would break off where the dowel comes out of the workpiece. First turn the blank to a cylinder using the roughing gouge. Keep the bevel on the wood, move the tool in the direction the flute is pointing and cut on the low side of the tool. Next you'll work on shaping. Begin the shaping by making a few cuts with a parting tool. This roughs in the general shape of the piece. You are getting excess Here I have knocked out the crosspiece of the chuck key and mounted it in a power driver. This speeds mounting, as the chuck must be very tight (almost, but not quite enough, to crush the dowel) to hold the piece securely during turning. A chuck that will accept a draw rod is available at Penn State (800-377-7297 or pennstateind.com). Chuck Chuck key mounted / in driver 42 Popular Woodworking October 2004 |