Popular Woodworking 2004-10 № 143, страница 45

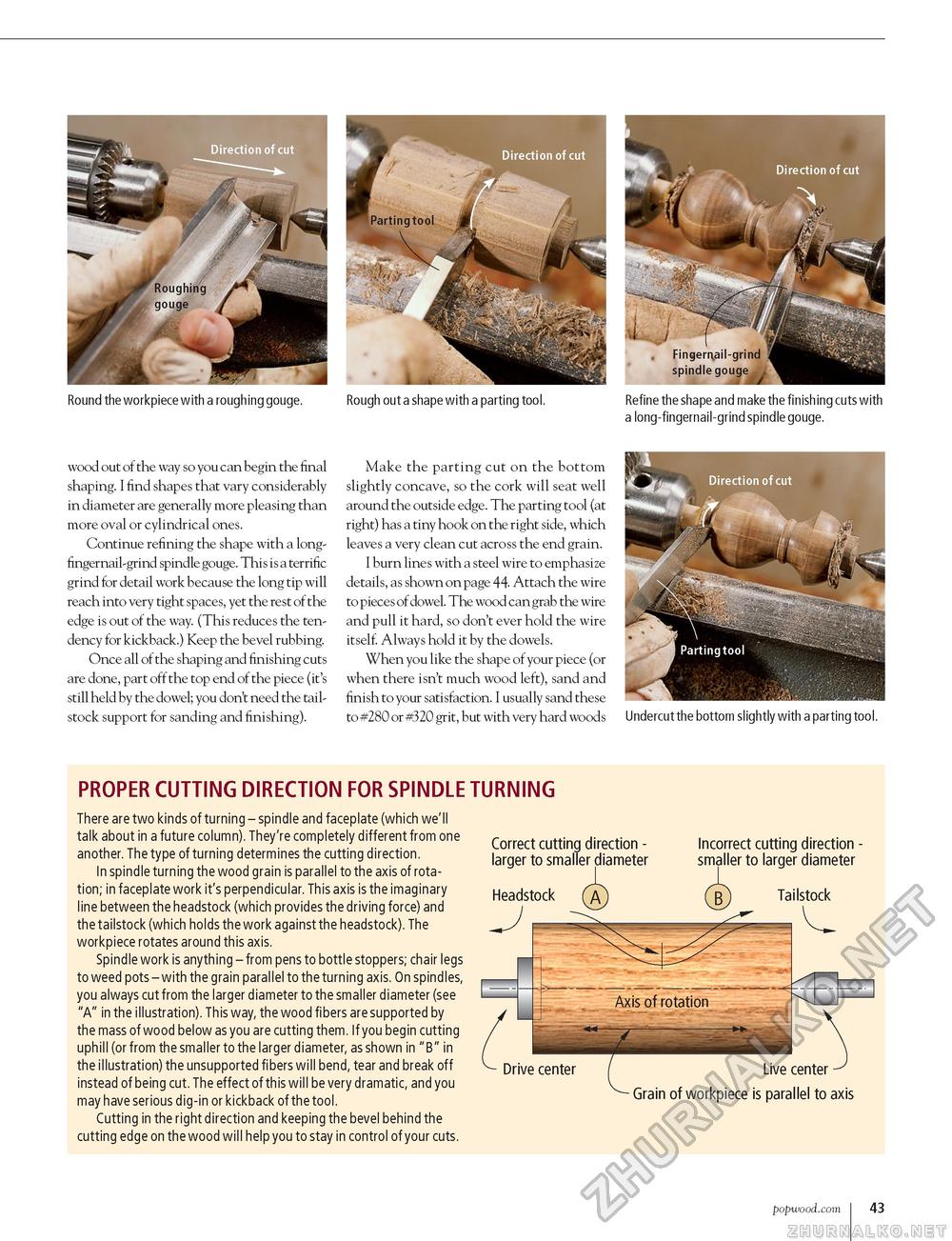

Round the workpiece with a roughing gouge. Rough out a shape with a parting tool. Refine the shape and make the finishing cuts with a long-fingernail-grind spindle gouge. wood out of the way so you can begin the final shaping. I find shapes that vary considerably in diameter are generally more pleasing than more oval or cylindrical ones. Continue refining the shape with a long-fingernail-grind spindle gouge. This is a terrific grind for detail work because the long tip will reach into very tight spaces, yet the rest of the edge is out of the way. (This reduces the tendency for kickback.) Keep the bevel rubbing. Once all of the shaping and finishing cuts are done, part off the top end of the piece (it's still held by the dowel; you don't need the tail-stock support for sanding and finishing). Make the parting cut on the bottom slightly concave, so the cork will seat well around the outside edge. The parting tool (at right) has a tiny hook on the right side, which leaves a very clean cut across the end grain. I burn lines with a steel wire to emphasize details, as shown on page 44. Attach the wire to pieces of dowel. The wood can grab the wire and pull it hard, so don't ever hold the wire itself. Always hold it by the dowels. When you like the shape of your piece (or when there isn't much wood left), sand and finish to your satisfaction. I usually sand these to #280 or #320 grit, but with very hard woods Undercut the bottom slightly with a parting tool. PROPER CUTTING DIRECTION FOR SPINDLE TURNING There are two kinds of turning - spindle and faceplate (which we'll talk about in a future column). They're completely different from one another. The type of turning determines the cutting direction. In spindle turning the wood grain is parallel to the axis of rotation; in faceplate work it's perpendicular. This axis is the imaginary line between the headstock (which provides the driving force) and the tailstock (which holds the work against the headstock). The workpiece rotates around this axis. Spindle work is anything - from pens to bottle stoppers; chair legs to weed pots - with the grain parallel to the turning axis. On spindles, you always cut from the larger diameter to the smaller diameter (see "A" in the illustration). This way, the wood fibers are supported by the mass of wood below as you are cutting them. If you begin cutting uphill (or from the smaller to the larger diameter, as shown in "B" in the illustration) the unsupported fibers will bend, tear and break off instead of being cut. The effect of this will be very dramatic, and you may have serious dig-in or kickback of the tool. Cutting in the right direction and keeping the bevel behind the cutting edge on the wood will help you to stay in control of your cuts. Correct cutting direction -larger to smaller diameter Headstock Incorrect cutting direction -smaller to larger diameter Tailstock Live center Grain of workpiece is parallel to axis popwood.com 43 |