Popular Woodworking 2004-11 № 144, страница 36

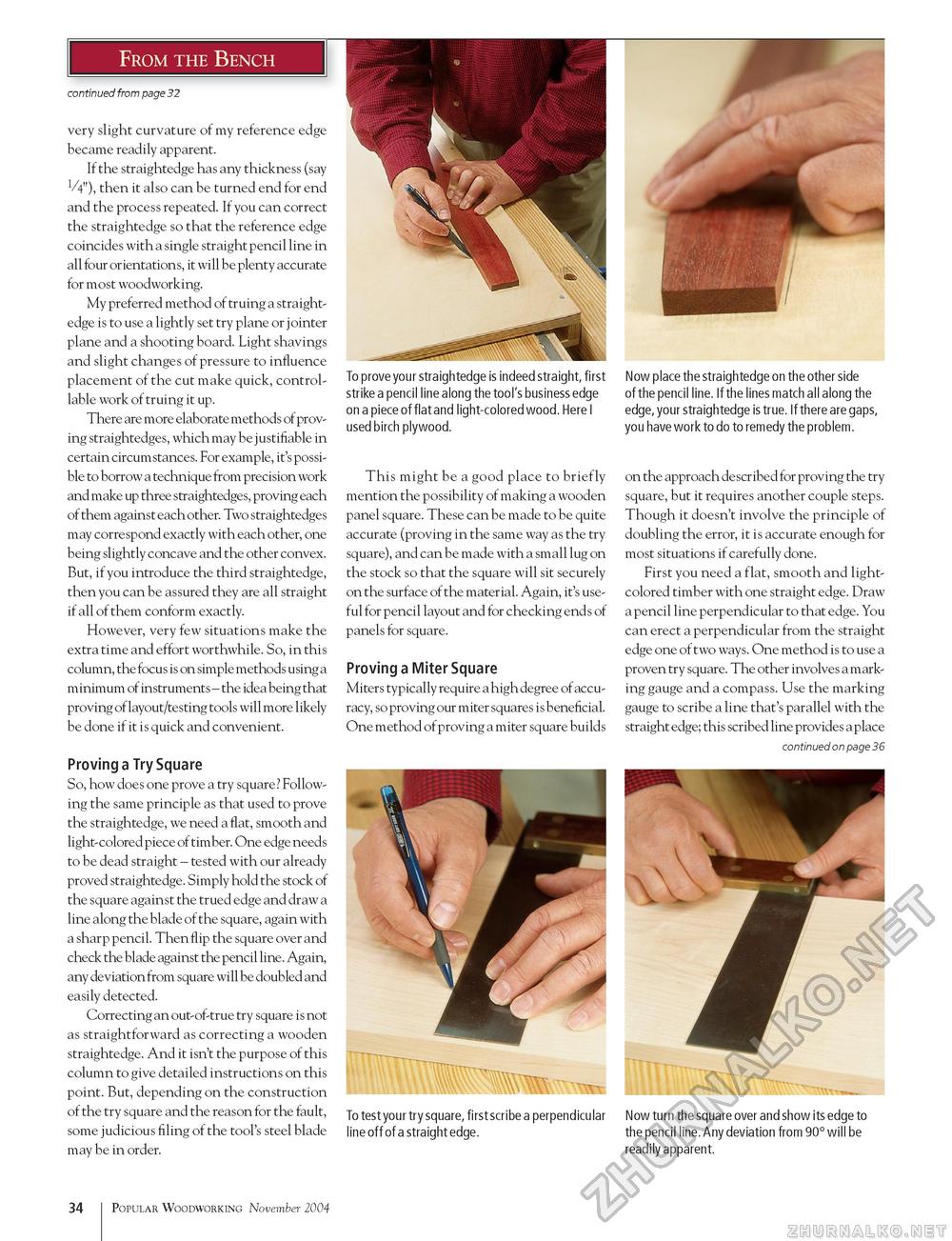

From the Bench continued from page 32 very slight curvature of my reference edge became readily apparent. If the straightedge has any thickness (say W'), then it also can be turned end for end and the process repeated. If you can correct the straightedge so that the reference edge coincides with a single straight pencil line in all four orientations, it will be plenty accurate for most woodworking. My preferred method of truing a straightedge is to use a lightly set try plane or j ointer plane and a shooting board. Light shavings and slight changes of pressure to influence placement of the cut make quick, controllable work of truing it up. There are more elaborate methods of proving straightedges, which may be justifiable in certain circumstances. For example, it's possible to borrow a technique from precision work and make up three straightedges, proving each of them against each other. Two straightedges may correspond exactly with each other, one being slightly concave and the other convex. But, if you introduce the third straightedge, then you can be assured they are all straight if all of them conform exactly. However, very few situations make the extra time and effort worthwhile. So, in this column, the focus is on simple methods using a minimum of instruments - the idea being that proving of layout/testing tools will more likely be done if it is quick and convenient. Proving a Try Square So, how does one prove a try square? Following the same principle as that used to prove the straightedge, we need a flat, smooth and light-colored piece of timber. One edge needs to be dead straight - tested with our already proved straightedge. Simply hold the stock of the square against the trued edge and draw a line along the blade of the square, again with a sharp pencil. Then flip the square over and check the blade against the pencil line. Again, any deviation from square will be doubled and easily detected. Correcting an out-of-true try square is not as straightforward as correcting a wooden straightedge. And it isn't the purpose of this column to give detailed instructions on this point. But, depending on the construction of the try square and the reason for the fault, some judicious filing of the tool's steel blade may be in order. To prove your straightedge is indeed straight, first strike a pencil line along the tool's business edge on a piece of flat and light-colored wood. Here I used birch plywood. This might be a good place to briefly mention the possibility of making a wooden panel square. These can be made to be quite accurate (proving in the same way as the try square), and can be made with a small lug on the stock so that the square will sit securely on the surface of the material. Again, it's useful for pencil layout and for checking ends of panels for square. Proving a Miter Square Miters typically require a high degree of accuracy, so proving our miter squares is beneficial. One method of proving a miter square builds To test your try square, first scribe a perpendicular line off of a straight edge. Now place the straightedge on the other side of the pencil line. If the lines match all along the edge, your straightedge is true. If there are gaps, you have work to do to remedy the problem. on the approach described for proving the try square, but it requires another couple steps. Though it doesn't involve the principle of doubling the error, it is accurate enough for most situations if carefully done. First you need a flat, smooth and light-colored timber with one straight edge. Draw a pencil line perpendicular to that edge. You can erect a perpendicular from the straight edge one of two ways. One method is to use a proven try square. The other involves a marking gauge and a compass. Use the marking gauge to scribe a line that's parallel with the straight edge; this scribed line provides a place continued on page 36 Now turn the square over and show its edge to the pencil line. Any deviation from 90° will be readily apparent. 34 Popular Woodworking November 2004 |