Popular Woodworking 2004-11 № 144, страница 49

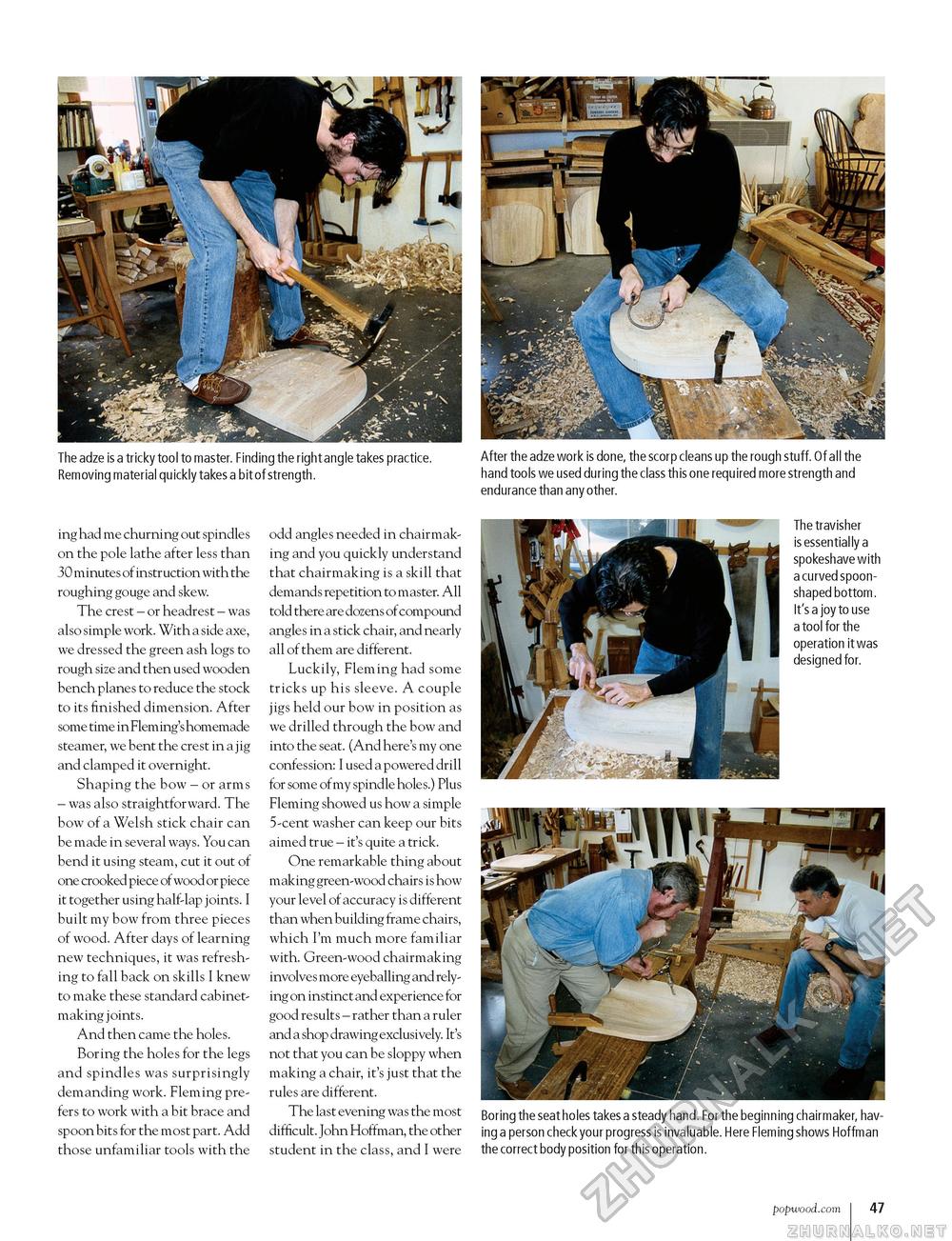

After the adze work is done, the scorp cleans up the rough stuff. Of all the hand tools we used during the class this one required more strength and endurance than any other. ing had me churning out spindle s on the pole lathe after less than 30 minutes of instruction with the roughing gouge and skew. The crest - or headrest - was also simple work. With a side axe, we dressed the green ash logs to rough size and then used wooden bench planes to reduce the stock to its finished dimension. After some time in Fleming's homemade steamer, we bent the crest in a jig and clamped it overnight. Shaping the bow - or arms - was also straightforward. The bow of a Welsh stick chair can be made in several ways. You can bend it using steam, cut it out of one crooked piece of wood or piece it together using half-lap joints. I built my bow from three pieces of wood. After days of learning new techniques, it was refreshing to fall back on skills I knew to make these standard cabinet-making joints. And then came the holes. Boring the holes for the legs and spindles was surprisingly demanding work. Fleming prefers to work with a bit brace and spoon bits for the most part. Add those unfamiliar tools with the odd angles needed in chairmak-ing and you quickly understand that chairmaking is a skill that demands repetition to master. All told there are dozens of compound angles in a stick chair, and nearly all of them are different. Luckily, Fleming had some tricks up his sleeve. A couple jigs held our bow in position as we drilled through the bow and into the seat. (And here's my one confession: I used a powered drill for some of my spindle holes.) Plus Fleming showed us how a simple 5-cent washer can keep our bits aimed true - it's quite a trick. One remarkable thing about making green-wood chairs is how your level of accuracy is different than when building frame chairs, which I'm much more familiar with. Green-wood chairmaking involves more eyeballing and relying on instinct and experience for good results - rather than a ruler and a shop drawing exclusively. It's not that you can be sloppy when making a chair, it's just that the rules are different. The last evening was the most difficult. John Hoffman, the other student in the class, and I were The travisher is essentially a spokeshave with a curved spoon-shaped bottom. It's a joy to use a tool for the operation it was designed for. Boring the seat holes takes a steady hand. For the beginning chairmaker, having a person check your progress is invaluable. Here Fleming shows Hoffman the correct body position for this operation. popwood.com 47 |