Popular Woodworking 2004-11 № 144, страница 52

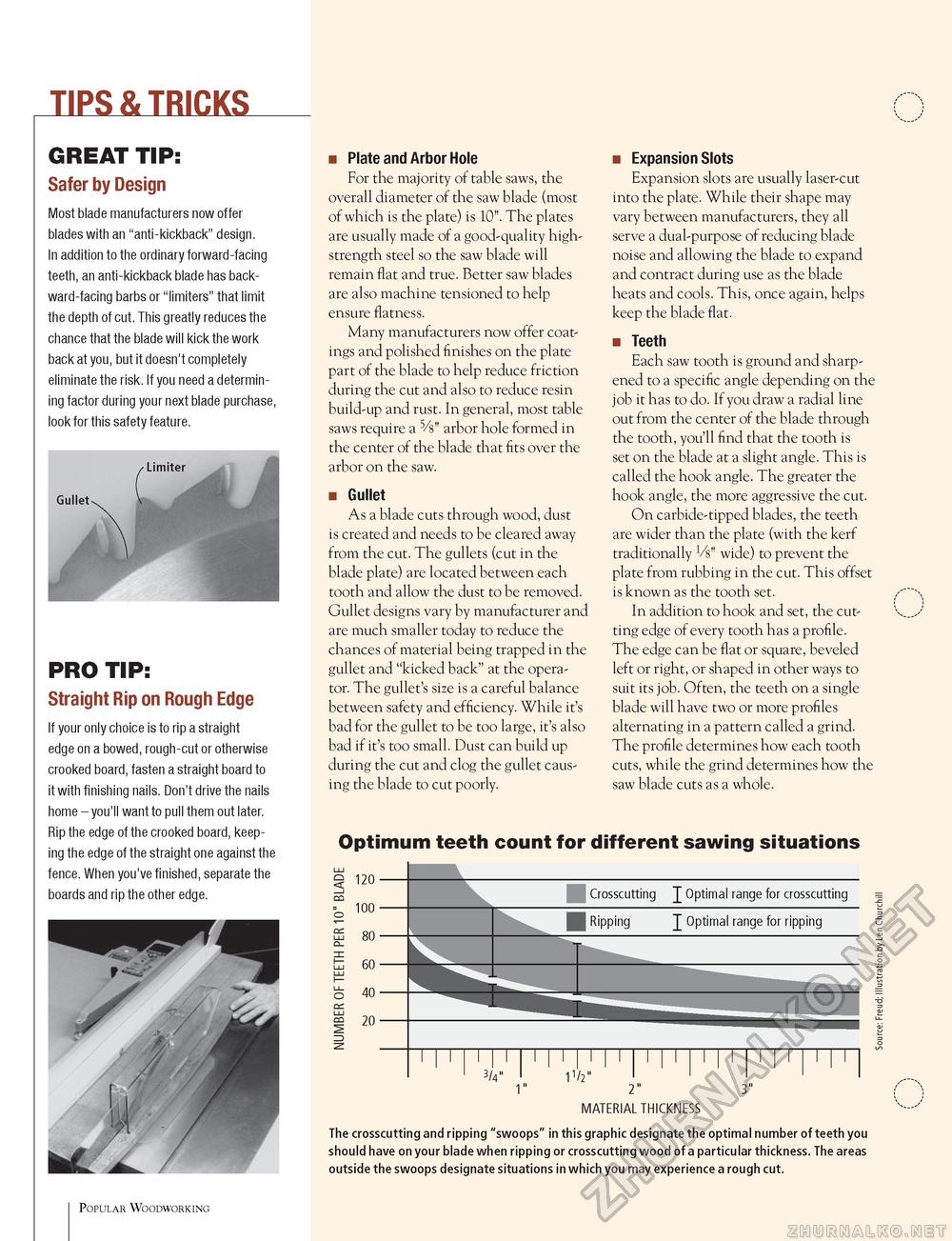

TIPS & TRICKS GREAT TIP: Safer by Design Most blade manufacturers now offer blades with an "anti-kickback" design. In addition to the ordinary forward-facing teeth, an anti-kickback blade has backward-facing barbs or "limiters" that limit the depth of cut. This greatly reduces the chance that the blade will kick the work back at you, but it doesn't completely eliminate the risk. If you need a determining factor during your next blade purchase, look for this safety feature. PRO TIP: Straight Rip on Rough Edge If your only choice is to rip a straight edge on a bowed, rough-cut or otherwise crooked board, fasten a straight board to it with finishing nails. Don't drive the nails home - you'll want to pull them out later. Rip the edge of the crooked board, keeping the edge of the straight one against the fence. When you've finished, separate the boards and rip the other edge. Popular Woodworking ■ Plate and Arbor Hole For the majority of table saws, the overall diameter of the saw blade (most of which is the plate) is 10". The plates are usually made of a good-quality high-strength steel so the saw blade will remain flat and true. Better saw blades are also machine tensioned to help ensure flatness. Many manufacturers now offer coatings and polished finishes on the plate part of the blade to help reduce friction during the cut and also to reduce resin build-up and rust. In general, most table saws require a 5/s" arbor hole formed in the center of the blade that fits over the arbor on the saw. ■ Gullet As a blade cuts through wood, dust is created and needs to be cleared away from the cut. The gullets (cut in the blade plate) are located between each tooth and allow the dust to be removed. Gullet designs vary by manufacturer and are much smaller today to reduce the chances of material being trapped in the gullet and "kicked back" at the operator. The gullet's size is a careful balance between safety and efficiency. While it's bad for the gullet to be too large, it's also bad if it's too small. Dust can build up during the cut and clog the gullet causing the blade to cut poorly. ■ Expansion Slots Expansion slots are usually laser-cut into the plate. While their shape may vary between manufacturers, they all serve a dual-purpose of reducing blade noise and allowing the blade to expand and contract during use as the blade heats and cools. This, once again, helps keep the blade flat. ■ Teeth Each saw tooth is ground and sharpened to a specific angle depending on the job it has to do. If you draw a radial line out from the center of the blade through the tooth, you'll find that the tooth is set on the blade at a slight angle. This is called the hook angle. The greater the hook angle, the more aggressive the cut. On carbide-tipped blades, the teeth are wider than the plate (with the kerf traditionally Vs" wide) to prevent the plate from rubbing in the cut. This offset is known as the tooth set. In addition to hook and set, the cutting edge of every tooth has a profile. The edge can be flat or square, beveled left or right, or shaped in other ways to suit its job. Often, the teeth on a single blade will have two or more profiles alternating in a pattern called a grind. The profile determines how each tooth cuts, while the grind determines how the saw blade cuts as a whole. Optimum teeth count for different sawing situations

Crosscutting J Optimal range for crosscutting | Ripping J Optimal range for ripping 3/4" 1" IV 2" 3" MATERIAL THICKNESS The crosscutting and ripping "swoops" in this graphic designate the optimal number of teeth you should have on your blade when ripping or crosscutting wood of a particular thickness. The areas outside the swoops designate situations in which you may experience a rough cut. |