Popular Woodworking 2004-11 № 144, страница 53

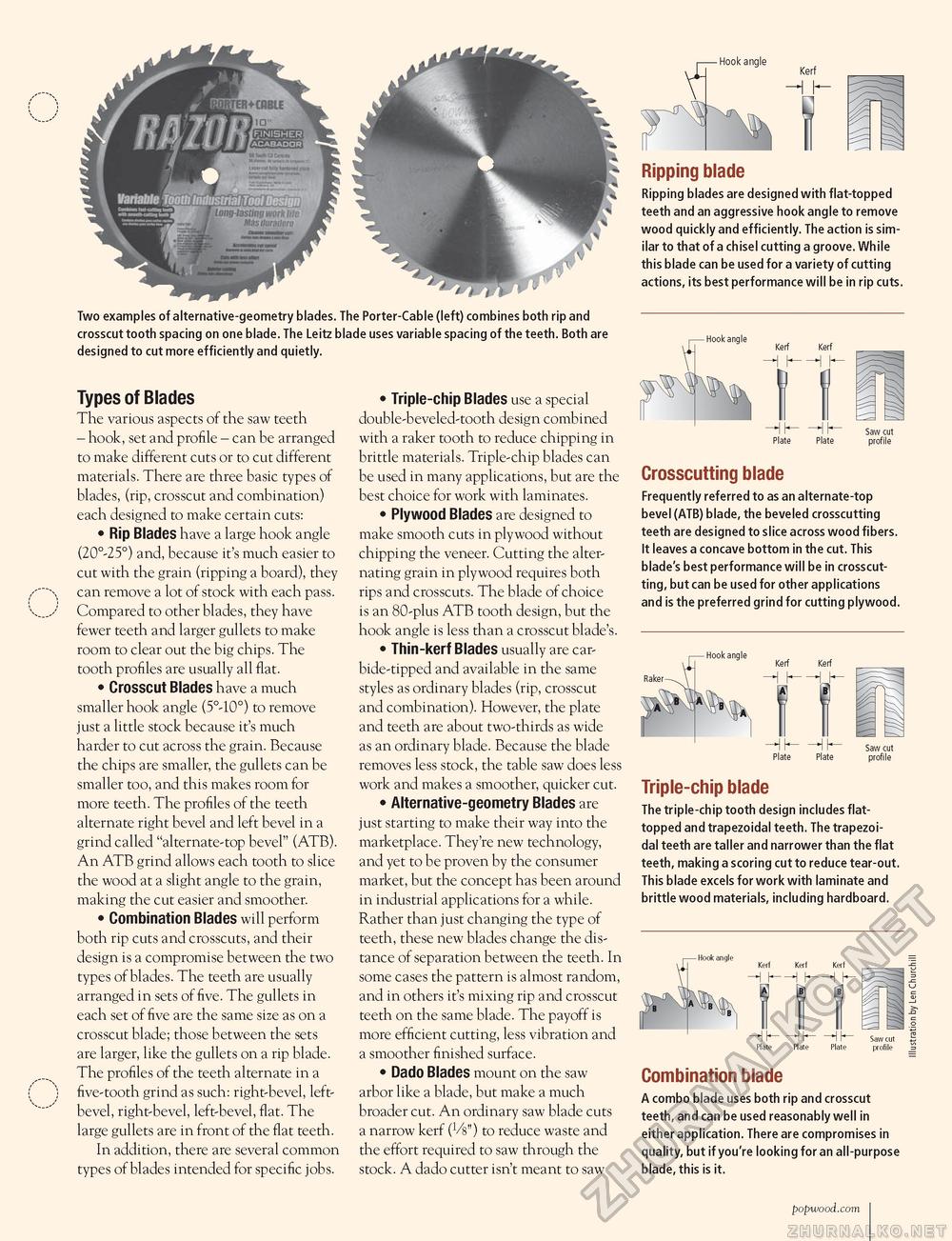

Two examples of alternative-geometry blades. The Porter-Cable (left) combines both rip and crosscut tooth spacing on one blade. The Leitz blade uses variable spacing of the teeth. Both are designed to cut more efficiently and quietly. Types of Blades The various aspects of the saw teeth - hook, set and profile - can be arranged to make different cuts or to cut different materials. There are three basic types of blades, (rip, crosscut and combination) each designed to make certain cuts: • Rip Blades have a large hook angle (20°-25°) and, because it's much easier to cut with the grain (ripping a board), they can remove a lot of stock with each pass. Compared to other blades, they have fewer teeth and larger gullets to make room to clear out the big chips. The tooth profiles are usually all flat. • Crosscut Blades have a much smaller hook angle (5°-10°) to remove just a little stock because it's much harder to cut across the grain. Because the chips are smaller, the gullets can be smaller too, and this makes room for more teeth. The profiles of the teeth alternate right bevel and left bevel in a grind called "alternate-top bevel" (ATB). An ATB grind allows each tooth to slice the wood at a slight angle to the grain, making the cut easier and smoother. • Combination Blades will perform both rip cuts and crosscuts, and their design is a compromise between the two types of blades. The teeth are usually arranged in sets of five. The gullets in each set of five are the same size as on a crosscut blade; those between the sets are larger, like the gullets on a rip blade. The profiles of the teeth alternate in a five-tooth grind as such: right-bevel, left-bevel, right-bevel, left-bevel, flat. The large gullets are in front of the flat teeth. In addition, there are several common types of blades intended for specific jobs. Hook angle lii Kerf 0 • Triple-chip Blades use a special double-beveled-tooth design combined with a raker tooth to reduce chipping in brittle materials. Triple-chip blades can be used in many applications, but are the best choice for work with laminates. • Plywood Blades are designed to make smooth cuts in plywood without chipping the veneer. Cutting the alternating grain in plywood requires both rips and crosscuts. The blade of choice is an 80-plus ATB tooth design, but the hook angle is less than a crosscut blade's. • Thin-kerf Blades usually are carbide-tipped and available in the same styles as ordinary blades (rip, crosscut and combination). However, the plate and teeth are about two-thirds as wide as an ordinary blade. Because the blade removes less stock, the table saw does less work and makes a smoother, quicker cut. • Alternative-geometry Blades are just starting to make their way into the marketplace. They're new technology, and yet to be proven by the consumer market, but the concept has been around in industrial applications for a while. Rather than just changing the type of teeth, these new blades change the distance of separation between the teeth. In some cases the pattern is almost random, and in others it's mixing rip and crosscut teeth on the same blade. The payoff is more efficient cutting, less vibration and a smoother finished surface. • Dado Blades mount on the saw arbor like a blade, but make a much broader cut. An ordinary saw blade cuts a narrow kerf (V8") to reduce waste and the effort required to saw through the stock. A dado cutter isn't meant to saw Saw cut Plate Plate profile Ripping blade Ripping blades are designed with flat-topped teeth and an aggressive hook angle to remove wood quickly and efficiently. The action is similar to that of a chisel cutting a groove. While this blade can be used for a variety of cutting actions, its best performance will be in rip cuts. Hookangle Crosscutting blade Frequently referred to as an alternate-top bevel (ATB) blade, the beveled crosscutting teeth are designed to slice across wood fibers. It leaves a concave bottom in the cut. This blade's best performance will be in crosscutting, but can be used for other applications and is the preferred grind for cutting plywood. -Hookangle Plate Plate Triple-chip blade The triple-chip tooth design includes flat-topped and trapezoidal teeth. The trapezoidal teeth are taller and narrower than the flat teeth, making a scoring cut to reduce tear-out. This blade excels for work with laminate and brittle wood materials, including hardboard. - Hook angle Saw cut Plate profile J3 Combination blade A combo blade uses both rip and crosscut teeth, and can be used reasonably well in either application. There are compromises in quality, but if you're looking for an all-purpose blade, this is it. popwood.com 53 |