Popular Woodworking 2004-11 № 144, страница 55

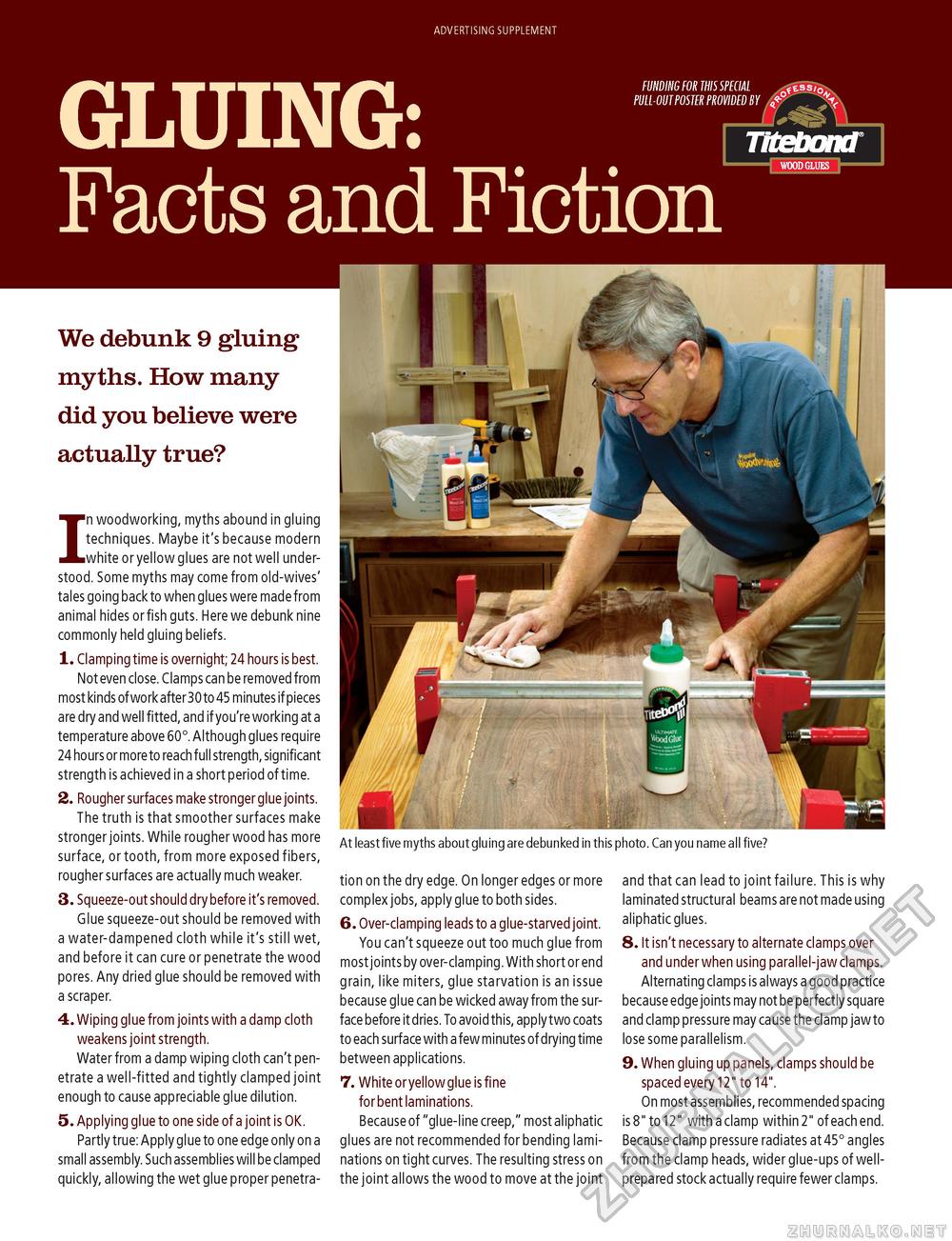

ADVERTISING SUPPLEMENT FUNDING FOR THIS Sf M 1 ■ ■ ■ ■ 1 PULL-OUTPOSTER PROV GLUING: I Facts and Fiction FUNDING FOR THIS SPECIAL <ess,0 PULL-OUTPOSTER PROVIDED BY \ Titebond We debunk 9 gluing myths. How many did you believe were actually true? In woodworking, myths abound in gluing techniques. Maybe it's because modern white or yellow glues are not well understood. Some myths may come from old-wives' tales going back to when glues were made from animal hides or fish guts. Here we debunk nine commonly held gluing beliefs. 1. Clamping time is overnight; 24 hours is best. Not even close. Clamps can be removed from most kinds of work after 30 to 45 minutes if pieces are dry and well fitted, and if you're working at a temperature above 60°. Although glues require 24 hours or more to reach full strength, significant strength is achieved in a short period of time. 2. Rougher surfaces make stronger glue joints. The truth is that smoother surfaces make stronger joints. While rougher wood has more surface, or tooth, from more exposed fibers, rougher surfaces are actually much weaker. 3. Squeeze-out should dry before it's removed. Glue squeeze-out should be removed with a water-dampened cloth while it's still wet, and before it can cure or penetrate the wood pores. Any dried glue should be removed with a scraper. 4. Wiping glue from joints with a damp cloth weakens joint strength. Water from a damp wiping cloth can't penetrate a well-fitted and tightly clamped joint enough to cause appreciable glue dilution. 5. Applying glue to one side of a joint is OK. Partly true: Apply glue to one edge only on a small assembly. Such assemblies will be clamped quickly, allowing the wet glue proper penetra At least five myths about gluing are debunked in this photo. Can you name all five? tion on the dry edge. On longer edges or more complex jobs, apply glue to both sides. 6. Over-clamping leads to a glue-starved joint. You can't squeeze out too much glue from most joints by over-clamping. With short or end grain, like miters, glue starvation is an issue because glue can be wicked away from the surface before it dries. To avoid this, apply two coats to each surface with a few minutes of drying time between applications. 7. White or yellow glue is fine for bent laminations. Because of "glue-line creep," most aliphatic glues are not recommended for bending laminations on tight curves. The resulting stress on the joint allows the wood to move at the joint and that can lead to joint failure. This is why laminated structural beams are not made using aliphatic glues. 8. It isn't necessary to alternate clamps over and under when using parallel-jaw clamps. Alternating clamps is always a good practice because edge joints may not be perfectly square and clamp pressure may cause the clamp jaw to lose some parallelism. 9. When gluing up panels, clamps should be spaced every 12" to 14". On most assemblies, recommended spacing is 8" to 12" with a clamp within 2" of each end. Because clamp pressure radiates at 45° angles from the clamp heads, wider glue-ups of well-prepared stock actually require fewer clamps. |