Popular Woodworking 2004-11 № 144, страница 56

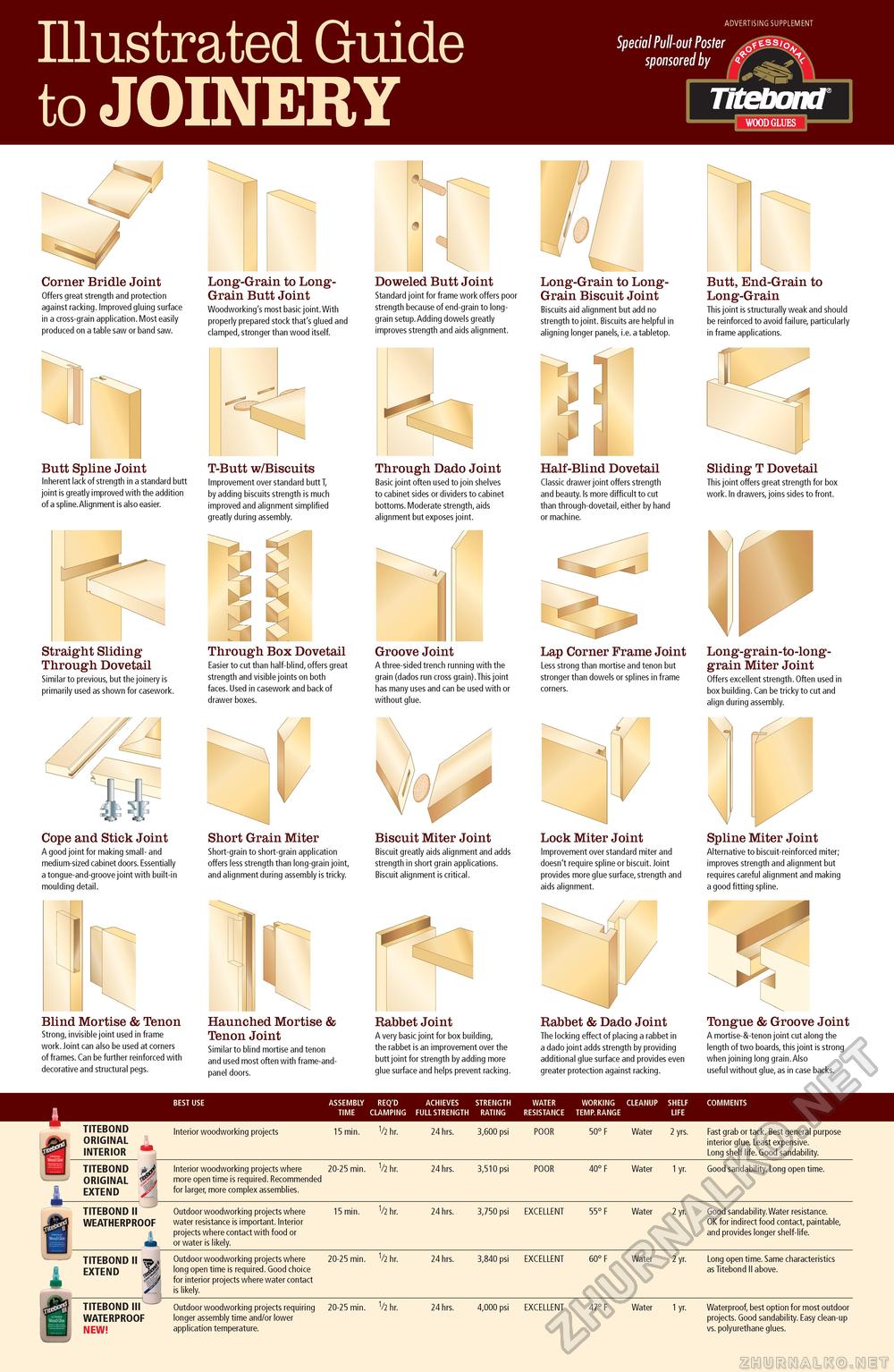

Illustrated Guide to JOINERY ADVERTISING SUPPLEMENT Special Pull-out Poster sponsored by ? "V Trtebond WOOD GLUES Corner Bridle Joint Offers great strength and protection against racking. Improved gluing surface in a cross-grain application. Most easily produced on a table saw or band saw. Long-Grain to Long-Grain Butt Joint Woodworking's most basic joint. With properly prepared stock that's glued and clamped, stronger than wood itself. Doweled Butt Joint Standard joint for frame work offers poor strength because of end-grain to long-grain setup. Adding dowels greatly improves strength and aids alignment. Long-Grain to Long-Grain Biscuit Joint Biscuits aid alignment but add no strength to joint. Biscuits are helpful in aligning longer panels, i.e. a tabletop. hi Butt, End-Grain to Long-Grain This joint is structurally weak and should be reinforced to avoid failure, particularly in frame applications. Butt Spline Joint Inherent lack of strength in a standard butt joint is greatly improved with the addition of a spline. Alignment is also easier. Straight Sliding Through Dovetail Similar to previous, but the joinery is primarily used as shown for casework. T-Butt w/Biscuits Improvement over standard butt T, by adding biscuits strength is much improved and alignment simplified greatly during assembly. Through Box Dovetail Easier to cut than half-blind, offers great strength and visible joints on both faces. Used in casework and back of drawer boxes. Through Dado Joint Basic joint often used to join shelves to cabinet sides or dividers to cabinet bottoms. Moderate strength, aids alignment but exposes joint. Groove Joint A three-sided trench running with the grain (dados run cross grain). This joint has many uses and can be used with or without glue. Half-Blind Dovetail Classic drawer joint offers strength and beauty. Is more difficult to cut than through-dovetail, either by hand or machine. Lap Corner Frame Joint Less strong than mortise and tenon but stronger than dowels or splines in frame corners. Sliding T Dovetail This joint offers great strength for box work. In drawers, joins sides to front. Long-grain-to-long-grain Miter Joint Offers excellent strength. Often used in box building. Can be tricky to cut and align during assembly. Cope and Stick Joint A good joint for making small- and medium-sized cabinet doors. Essentially a tongue-and-groove joint with built-in moulding detail. Short Grain Miter Short-grain to short-grain application offers less strength than long-grain joint, and alignment during assembly is tricky. Biscuit Miter Joint Biscuit greatly aids alignment and adds strength in short grain applications. Biscuit alignment is critical. Lock Miter Joint Improvement over standard miter and doesn't require spline or biscuit. Joint provides more glue surface, strength and aids alignment. i/ Spline Miter Joint Alternative to biscuit-reinforced miter; improves strength and alignment but requires careful alignment and making a good fitting spline. Blind Mortise & Tenon Strong, invisible joint used in frame work. Joint can also be used at corners of frames. Can be further reinforced with decorative and structural pegs. Haunched Mortise & Tenon Joint Similar to blind mortise and tenon and used most often with frame-and-panel doors. Rabbet Joint A very basic joint for box building, the rabbet is an improvement over the butt joint for strength by adding more glue surface and helps prevent racking. Rabbet & Dado Joint The locking effect of placing a rabbet in a dado joint adds strength by providing additional glue surface and provides even greater protection against racking. Tongue & Groove Joint A mortise-&-tenon joint cut along the length of two boards, this joint is strong when joining long grain. Also useful without glue, as in case backs. TITEBOND ORIGINAL INTERIOR M ORIGINAL 1 EXTEND TITEBOND II TITEBOND II EXTEND TITEBOND III v NEW!

|