Popular Woodworking 2004-11 № 144, страница 58

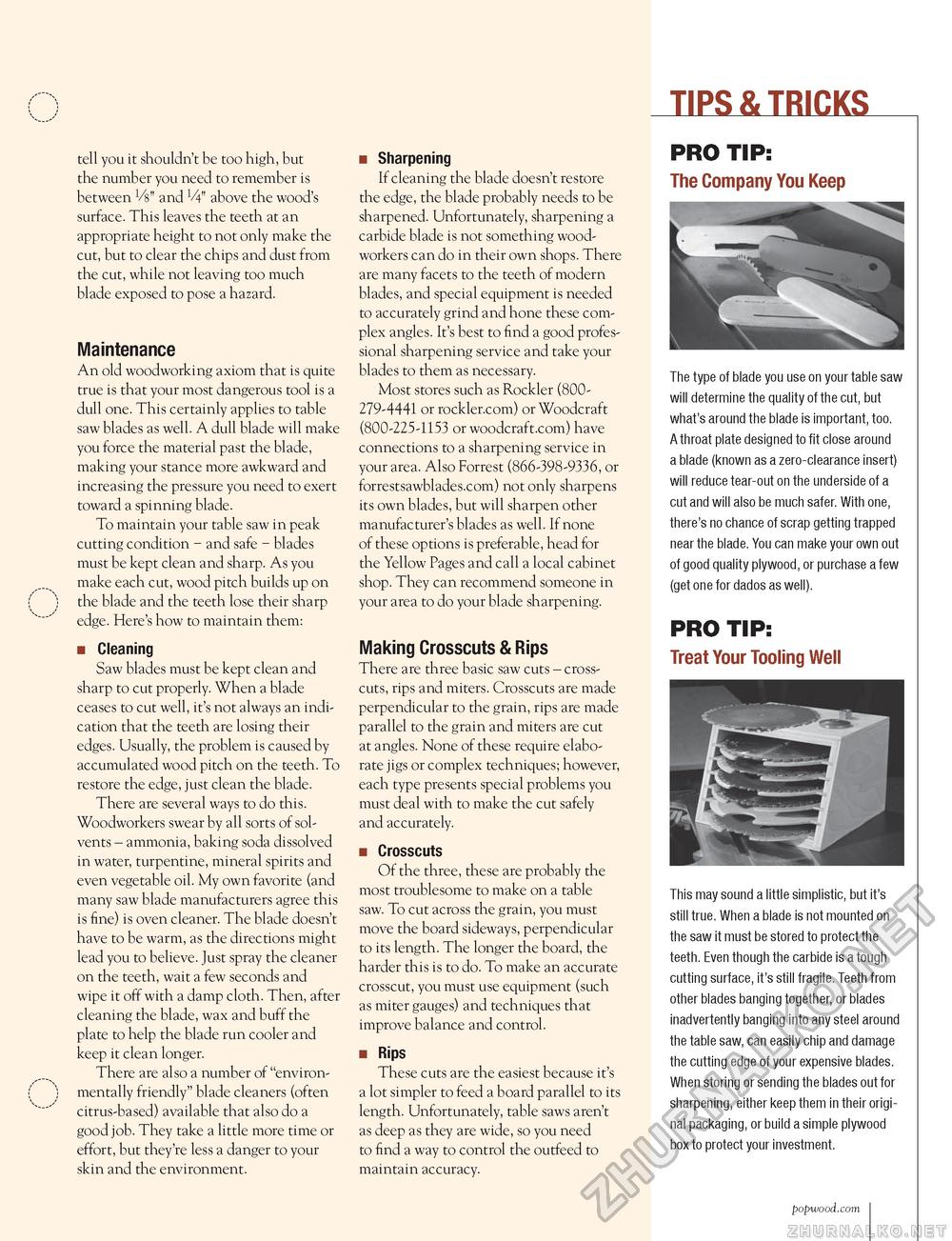

TIPS & TRICKS tell you it shouldn't be too high, but the number you need to remember is between V8" and V4" above the wood's surface. This leaves the teeth at an appropriate height to not only make the cut, but to clear the chips and dust from the cut, while not leaving too much blade exposed to pose a hazard. Maintenance An old woodworking axiom that is quite true is that your most dangerous tool is a dull one. This certainly applies to table saw blades as well. A dull blade will make you force the material past the blade, making your stance more awkward and increasing the pressure you need to exert toward a spinning blade. To maintain your table saw in peak cutting condition - and safe - blades must be kept clean and sharp. As you make each cut, wood pitch builds up on the blade and the teeth lose their sharp edge. Here's how to maintain them: ■ Cleaning Saw blades must be kept clean and sharp to cut properly. When a blade ceases to cut well, it's not always an indication that the teeth are losing their edges. Usually, the problem is caused by accumulated wood pitch on the teeth. To restore the edge, just clean the blade. There are several ways to do this. Woodworkers swear by all sorts of solvents - ammonia, baking soda dissolved in water, turpentine, mineral spirits and even vegetable oil. My own favorite (and many saw blade manufacturers agree this is fine) is oven cleaner. The blade doesn't have to be warm, as the directions might lead you to believe. Just spray the cleaner on the teeth, wait a few seconds and wipe it off with a damp cloth. Then, after cleaning the blade, wax and buff the plate to help the blade run cooler and keep it clean longer. There are also a number of "environmentally friendly" blade cleaners (often citrus-based) available that also do a good job. They take a little more time or effort, but they're less a danger to your skin and the environment. ■ Sharpening If cleaning the blade doesn't restore the edge, the blade probably needs to be sharpened. Unfortunately, sharpening a carbide blade is not something woodworkers can do in their own shops. There are many facets to the teeth of modern blades, and special equipment is needed to accurately grind and hone these complex angles. It's best to find a good professional sharpening service and take your blades to them as necessary. Most stores such as Rockler (800279-4441 or rockler.com) or Woodcraft (800-225-1153 or woodcraft.com) have connections to a sharpening service in your area. Also Forrest (866-398-9336, or forrestsawblades.com) not only sharpens its own blades, but will sharpen other manufacturer's blades as well. If none of these options is preferable, head for the Yellow Pages and call a local cabinet shop. They can recommend someone in your area to do your blade sharpening. Making Crosscuts & Rips There are three basic saw cuts - crosscuts, rips and miters. Crosscuts are made perpendicular to the grain, rips are made parallel to the grain and miters are cut at angles. None of these require elaborate jigs or complex techniques; however, each type presents special problems you must deal with to make the cut safely and accurately. ■ Crosscuts Of the three, these are probably the most troublesome to make on a table saw. To cut across the grain, you must move the board sideways, perpendicular to its length. The longer the board, the harder this is to do. To make an accurate crosscut, you must use equipment (such as miter gauges) and techniques that improve balance and control. ■ Rips These cuts are the easiest because it's a lot simpler to feed a board parallel to its length. Unfortunately, table saws aren't as deep as they are wide, so you need to find a way to control the outfeed to maintain accuracy. PRO TIP: The Company You Keep The type of blade you use on your table saw will determine the quality of the cut, but what's around the blade is important, too. A throat plate designed to fit close around a blade (known as a zero-clearance insert) will reduce tear-out on the underside of a cut and will also be much safer. With one, there's no chance of scrap getting trapped near the blade. You can make your own out of good quality plywood, or purchase a few (get one for dados as well). PRO TIP: Treat Your Tooling Well This may sound a little simplistic, but it's still true. When a blade is not mounted on the saw it must be stored to protect the teeth. Even though the carbide is a tough cutting surface, it's still fragile. Teeth from other blades banging together, or blades inadvertently banging into any steel around the table saw, can easily chip and damage the cutting edge of your expensive blades. When storing or sending the blades out for sharpening, either keep them in their original packaging, or build a simple plywood box to protect your investment. popwood.com 58 |