Popular Woodworking 2004-11 № 144, страница 90

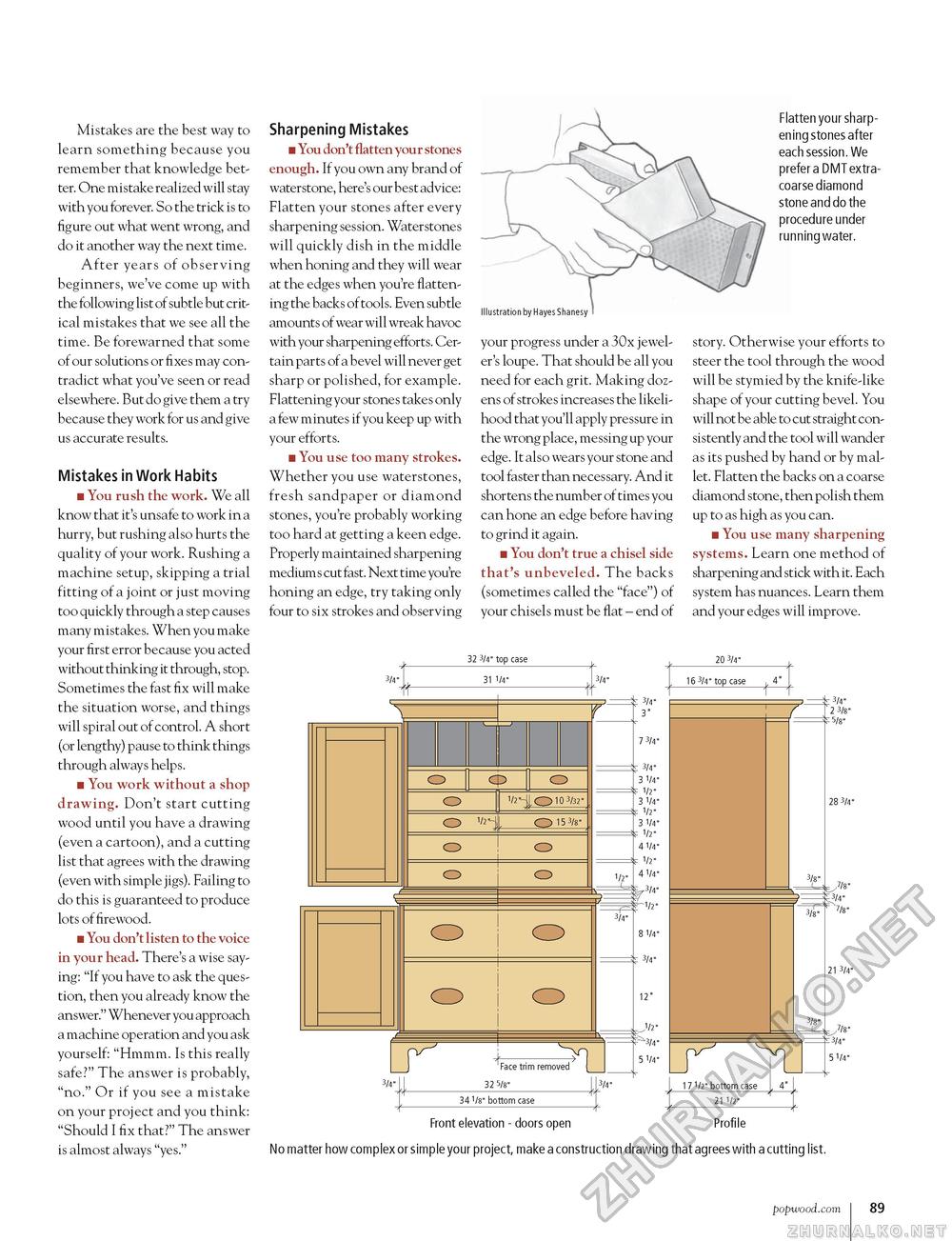

Mistakes are the best way to learn something because you remember that knowledge better. One mistake realized will stay with you forever. So the trick is to figure out what went wrong, and do it another way the next time. After years of observing beginners, we've come up with the following list of subtle but critical mistakes that we see all the time. Be forewarned that some of our solutions or fixes may contradict what you've seen or read elsewhere. But do give them a try because they work for us and give us accurate results. Mistakes in Work Habits ■ You rush the work. We all know that it's unsafe to work in a hurry, but rushing also hurts the quality of your work. Rushing a machine setup, skipping a trial fitting of a joint or just moving too quickly through a step causes many mistakes. When you make your first error because you acted without thinking it through, stop. Sometimes the fast fix will make the situation worse, and things will spiral out of control. A short (or lengthy) pause to think things through always helps. ■ You work without a shop drawing. Don't start cutting wood until you have a drawing (even a cartoon), and a cutting list that agrees with the drawing (even with simple jigs). Failing to do this is guaranteed to produce lots of firewood. ■ You don't listen to the voice in your head. There's a wise saying: "If you have to ask the question, then you already know the answer." Whenever you approach a machine operation and you ask yourself: "Hmmm. Is this really safe?" The answer is probably, "no." Or if you see a mistake on your project and you think: "Should I fix that?" The answer is almost always "yes." Flatten your sharpening stones after each session. We prefer a DMT extra-coarse diamond stone and do the procedure under running water. Illustration by Hayes Shanesy Sharpening Mistakes ■ You don't flatten your stones enough. If you own any brand of waterstone, here's our best advice: Flatten your stones after every sharpening session. Waterstones will quickly dish in the middle when honing and they will wear at the edges when you're flattening the backs of tools. Even subtle amounts of wear will wreak havoc with your sharpening efforts. Certain parts of a bevel will never get sharp or polished, for example. Flattening your stones takes only a few minute s if you keep up with your efforts. ■ You use too many strokes. Whether you use waterstones, fresh sandpaper or diamond stones, you're probably working too hard at getting a keen edge. Properly maintained sharpening medium s cut fast. Next time you're honing an edge, try taking only four to six strokes and observing your progress under a 30x jeweler's loupe. That should be all you need for each grit. Making dozens of strokes increases the likelihood that you'll apply pressure in the wrong place, messing up your edge. It also wears your stone and tool faster than necessary. And it shortens the number of times you can hone an edge before having to grind it again. ■ You don't true a chisel side that's unbeveled. The backs (sometimes called the "face") of your chisels must be flat - end of story. Otherwise your efforts to steer the tool through the wood will be stymied by the knife-like shape of your cutting bevel. You will not be able to cut straight consistently and the tool will wander as its pushed by hand or by mallet. Flatten the backs on a coarse diamond stone, then polish them up to as high as you can. ■ You use many sharpening systems. Learn one method of sharpening and stick with it. Each system has nuances. Learn them and your edges will improve. 32 3/4" top case 3/4" 32 3/4" top case

3/4"

7 3/4" 3/4" 3 1/4" 1/2" 3 1/4" 1/2" 3 1/4" 1/2" 4 1/4" 1/2" 4 1/4" 3/4" 1/2" 8 1/4" f 3/4" 12" 1/2" ^3/4" 5 1/4" _20 3/4"_ 16 3/4" top case ,4" 28 3/4" 21 3/4" 21 1/2" Profile Front elevation - doors open No matter how complex or simple your project, make a construction drawing that agrees with a cutting list. popwood.com 89 |