Popular Woodworking 2004-12 № 145, страница 49

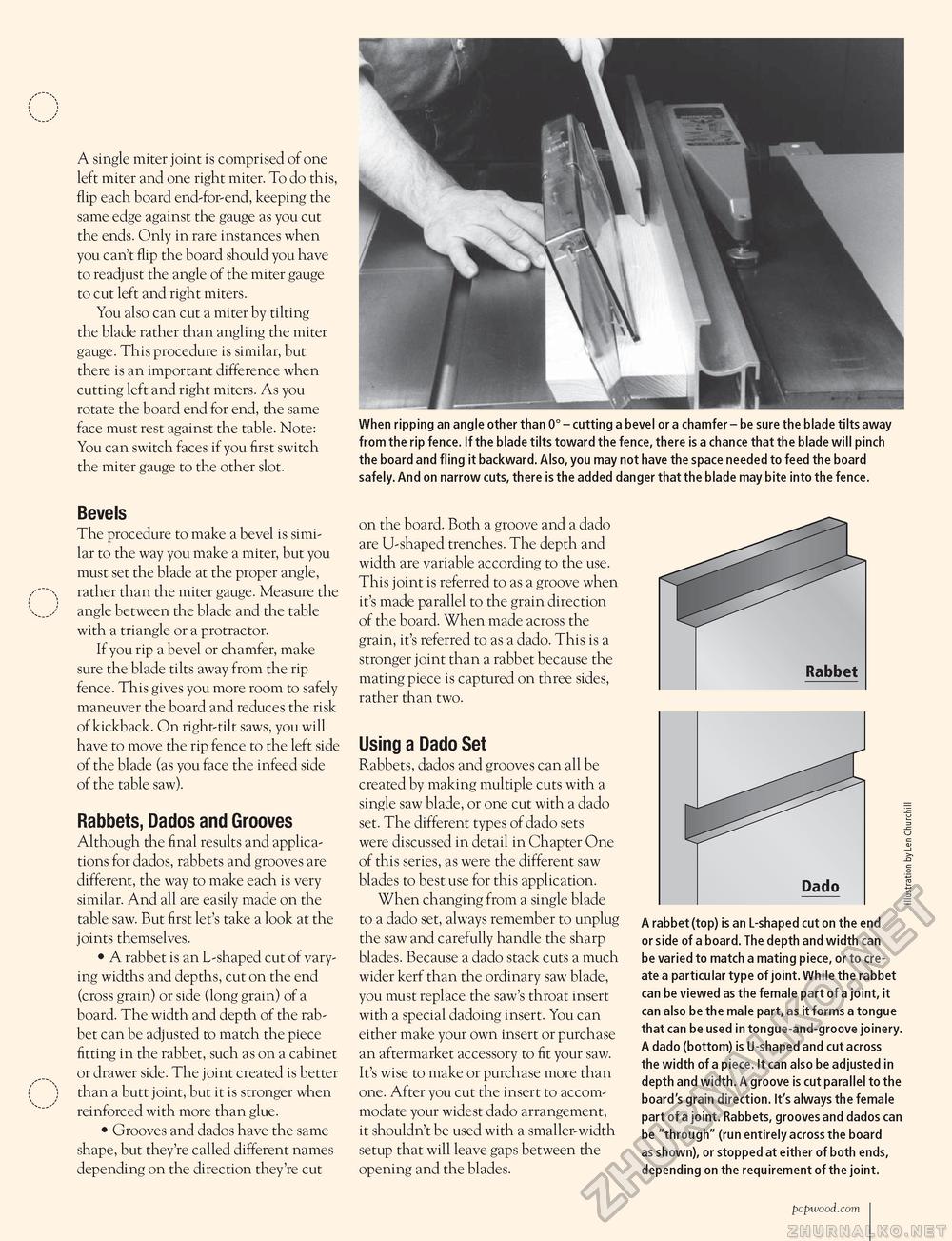

A single miter joint is comprised of one left miter and one right miter. To do this, flip each board end-for-end, keeping the same edge against the gauge as you cut the ends. Only in rare instances when you can't flip the board should you have to readjust the angle of the miter gauge to cut left and right miters. You also can cut a miter by tilting the blade rather than angling the miter gauge. This procedure is similar, but there is an important difference when cutting left and right miters. As you rotate the board end for end, the same face must rest against the table. Note: You can switch faces if you first switch the miter gauge to the other slot. Bevels The procedure to make a bevel is similar to the way you make a miter, but you must set the blade at the proper angle, rather than the miter gauge. Measure the angle between the blade and the table with a triangle or a protractor. If you rip a bevel or chamfer, make sure the blade tilts away from the rip fence. This gives you more room to safely maneuver the board and reduces the risk of kickback. On right-tilt saws, you will have to move the rip fence to the left side of the blade (as you face the infeed side of the table saw). Rabbets, Dados and Grooves Although the final results and applications for dados, rabbets and grooves are different, the way to make each is very similar. And all are easily made on the table saw. But first let's take a look at the joints themselves. • A rabbet is an L-shaped cut of varying widths and depths, cut on the end (cross grain) or side (long grain) of a board. The width and depth of the rabbet can be adjusted to match the piece fitting in the rabbet, such as on a cabinet or drawer side. The joint created is better than a butt joint, but it is stronger when reinforced with more than glue. • Grooves and dados have the same shape, but they're called different names depending on the direction they're cut When ripping an angle other than 0° - cutting a bevel or a chamfer - be sure the blade tilts away from the rip fence. If the blade tilts toward the fence, there is a chance that the blade will pinch the board and fling it backward. Also, you may not have the space needed to feed the board safely. And on narrow cuts, there is the added danger that the blade may bite into the fence. on the board. Both a groove and a dado are U-shaped trenches. The depth and width are variable according to the use. This joint is referred to as a groove when it's made parallel to the grain direction of the board. When made across the grain, it's referred to as a dado. This is a stronger joint than a rabbet because the mating piece is captured on three sides, rather than two. Using a Dado Set Rabbets, dados and grooves can all be created by making multiple cuts with a single saw blade, or one cut with a dado set. The different types of dado sets were discussed in detail in Chapter One of this series, as were the different saw blades to best use for this application. When changing from a single blade to a dado set, always remember to unplug the saw and carefully handle the sharp blades. Because a dado stack cuts a much wider kerf than the ordinary saw blade, you must replace the saw's throat insert with a special dadoing insert. You can either make your own insert or purchase an aftermarket accessory to fit your saw. It's wise to make or purchase more than one. After you cut the insert to accommodate your widest dado arrangement, it shouldn't be used with a smaller-width setup that will leave gaps between the opening and the blades. A rabbet (top) is an L-shaped cut on the end or side of a board. The depth and width can be varied to match a mating piece, or to create a particular type of joint. While the rabbet can be viewed as the female part of a joint, it can also be the male part, as it forms a tongue that can be used in tongue-and-groove joinery. A dado (bottom) is U-shaped and cut across the width of a piece. It can also be adjusted in depth and width. A groove is cut parallel to the board's grain direction. It's always the female part of a joint. Rabbets, grooves and dados can be "through" (run entirely across the board as shown), or stopped at either of both ends, depending on the requirement of the joint. popwood.com 101 |