Popular Woodworking 2005-02 № 146, страница 24

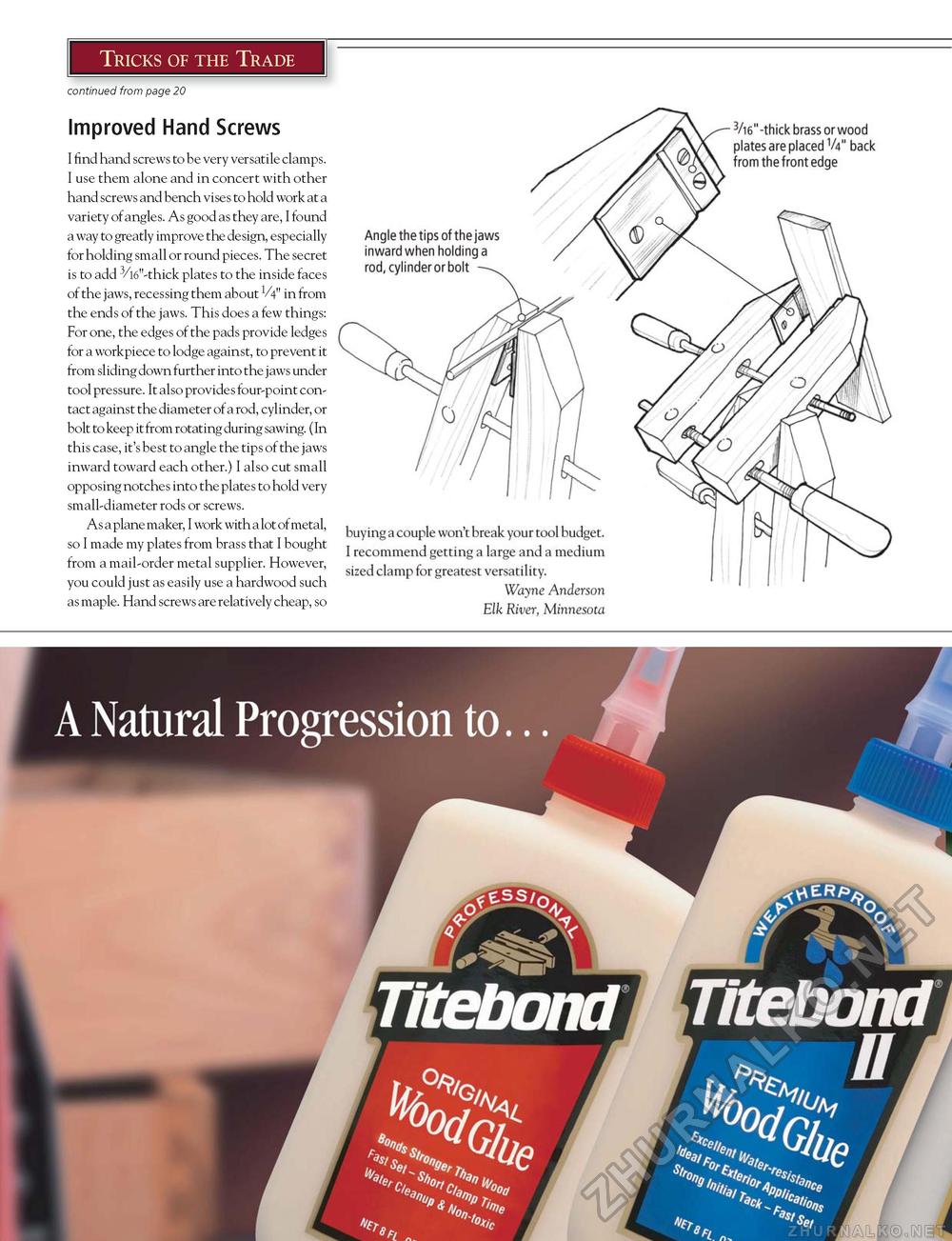

Tricks of the Trade continued from page 20 Improved Hand Screws I find hand screws to be very versatile clamps. I use them alone and in concert with other hand screws and bench vises to hold work at a variety of angles. As good as they are, I found a way to greatly improve the design, especially for holding small or round pieces. The secret is to add 3/16"-thick plates to the inside faces of the jaws, recessing them about 14" in from the ends of the jaws. This does a few things: For one, the edges of the pads provide ledges for a workpiece to lodge against, to prevent it from sliding down further into the jaws under tool pressure. It also provides four-point contact against the diameter of a rod, cylinder, or bolt to keep it from rotating during sawing. (In this case, it's best to angle the tips of the jaws inward toward each other.) I also cut small opposing notches into the plates to hold very small-diameter rods or screws. As a plane maker, I work with a lot of metal, so I made my plates from brass that I bought from a mail-order metal supplier. However, you could just as easily use a hardwood such as maple. Hand screws are relatively cheap, so Titebond Kr. **r ha— •tC, "Off ri Wea Ck % '3n 'a>»n fa, 'on ■to. 000 %e Vic |