Popular Woodworking 2005-02 № 146, страница 92

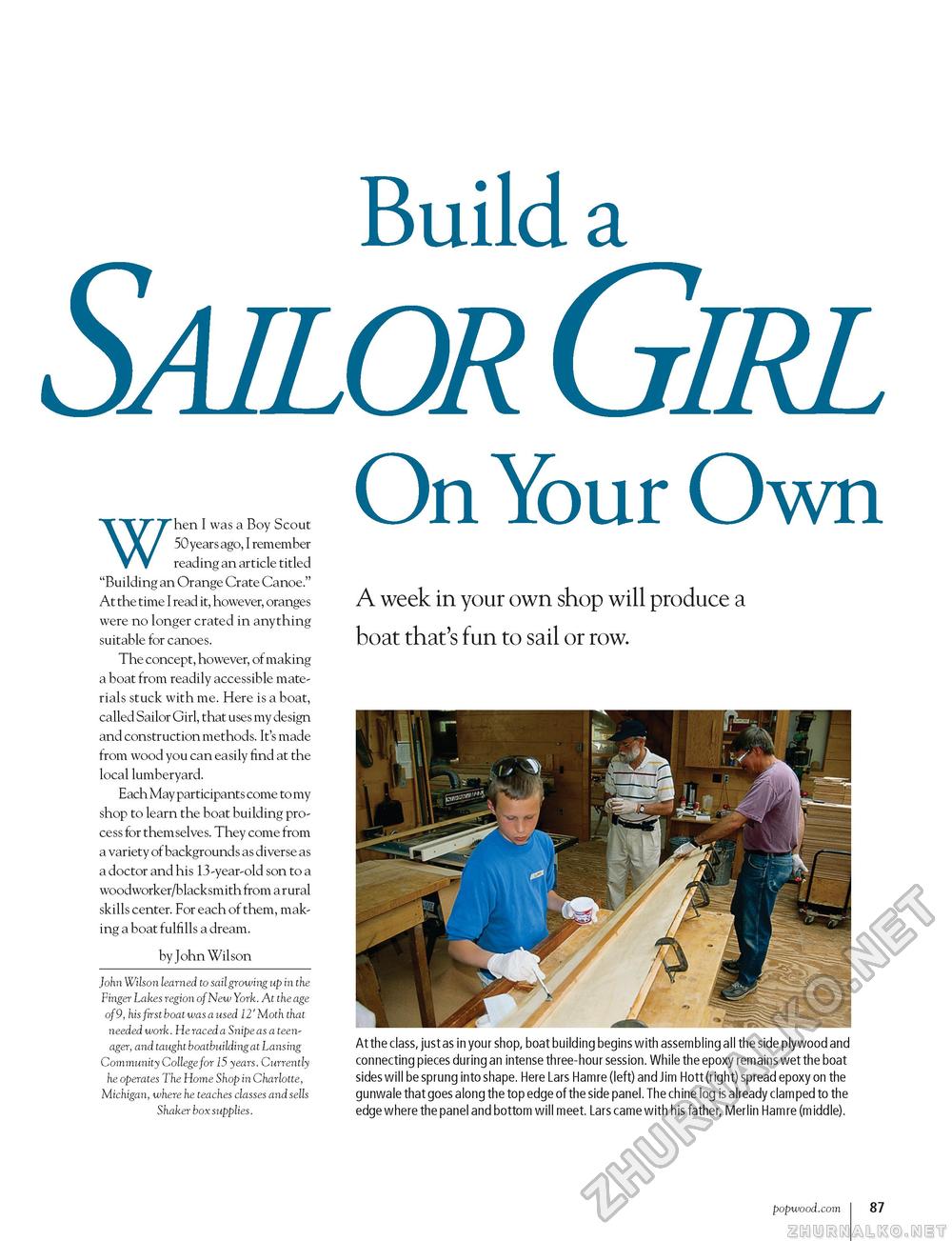

Build a When I was a Boy Scout 50 years ago, I remember reading an article titled "Building an Orange Crate Canoe." At the time I read it, however, oranges were no longer crated in anything suitable for canoes. The concept, however, of making a boat from readily accessible materials stuck with me. Here is a boat, called Sailor Girl, that uses my design and construction methods. It's made from wood you can easily find at the local lumberyard. Each May participants come to my shop to learn the boat building process for themselves. They come from a variety of backgrounds as diverse as a doctor and his 13-year-old son to a woodworker/blacksmith from a rural skills center. For each of them, making a boat fulfills a dream. by John Wilson John Wilson learned to sail growing up in the Finger Lakes region of New York. At the age of 9, his first boat was a used 12' Moth that needed work. He raced a Snipe as a teenager, and taught boatbuilding at Lansing Community College for 15 years. Currently he operates The Home Shop in Charlotte, Michigan, where he teaches classes and sells Shaker box supplies. On Your Own A week in your own shop will produce a boat that's fun to sail or row. At the class, just as in your shop, boat building begins with assembling all the side plywood and connecting pieces during an intense three-hour session. While the epoxy remains wet the boat sides will be sprung into shape. Here Lars Hamre (left) and Jim Hott (right) spread epoxy on the gunwale that goes along the top edge of the side panel. The chine log is already clamped to the edge where the panel and bottom will meet. Lars came with his father, Merlin Hamre (middle). popwood.com 87 |