Popular Woodworking 2005-06 № 148, страница 16

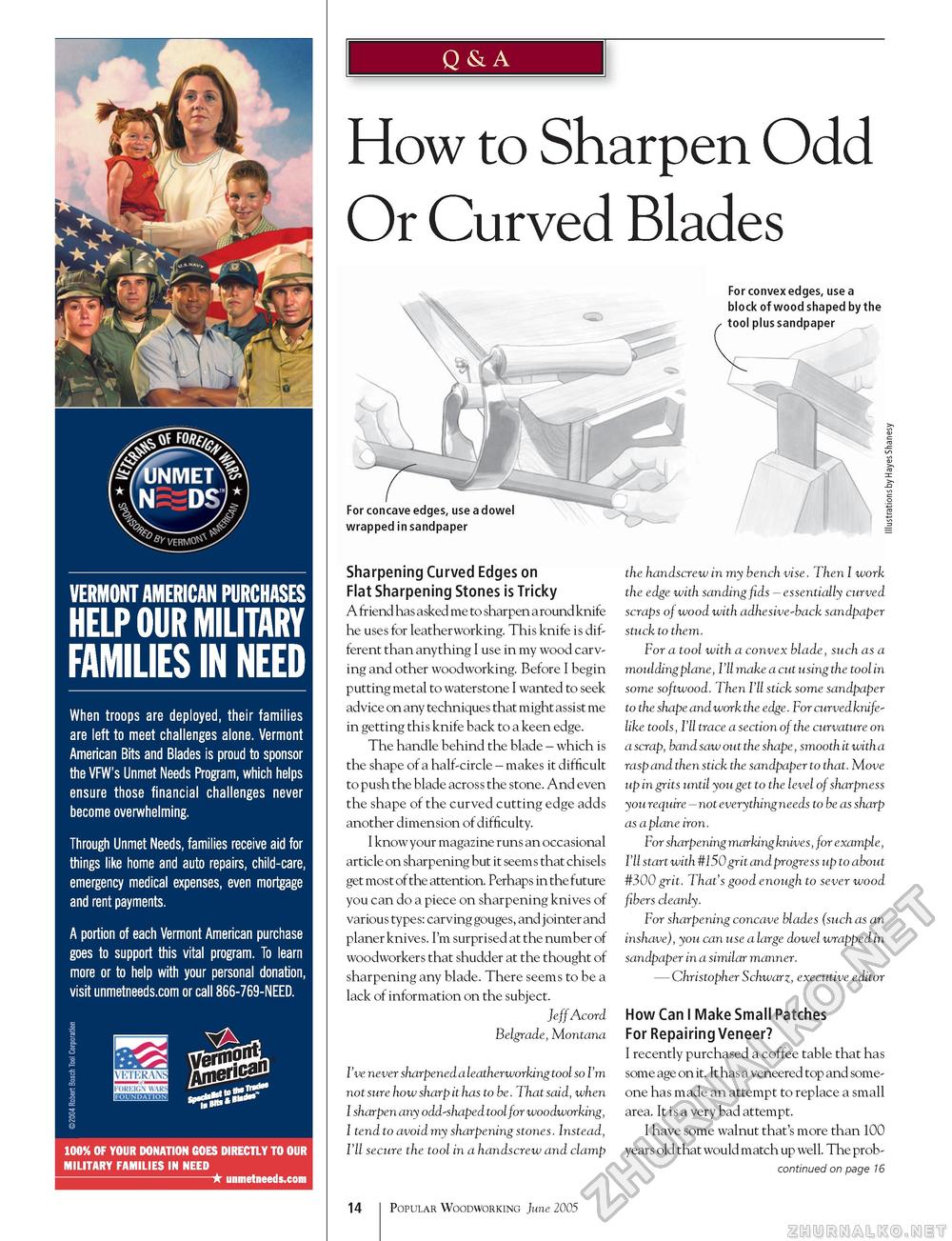

VERMONT AMERICAN PURCHASES HELP OUR MILITARY FAMILIES IN NEED When troops are deployed, their families are left to meet challenges alone. Vermont American Bits and Blades is proud to sponsor the VFW's Unmet Needs Program, which helps ensure those financial challenges never become overwhelming. Through Unmet Needs, families receive aid for things like home and auto repairs, child-care, emergency medical expenses, even mortgage and rent payments. A portion of each Vermont American purchase goes to support this vital program. To learn more or to help with your personal donation, visit unmetneeds.com or call 866-769-NEED. Q & A How to Sharpen Odd Or Curved Blades For convex edges, use a block of wood shaped by the tool plus sandpaper For concave edges, use a dowel wrapped in sandpaper Sharpening Curved Edges on Flat Sharpening Stones is Tricky A friend has asked me to sharpen a round knife he uses for leatherworking. This knife is different than anything I use in my wood carving and other woodworking. Before I begin putting metal to waterstone I wanted to seek advice on any techniques that might assist me in getting this knife back to a keen edge. The handle behind the blade - which is the shape of a half-circle - makes it difficult to push the blade across the stone. And even the shape of the curved cutting edge adds another dimension of difficulty. I know your magazine runs an occasional article on sharpening but it seems that chisels get most of the attention. Perhaps in the future you can do a piece on sharpening knives of various types: carving gouges, and jointer and planer knives. I'm surprised at the number of woodworkers that shudder at the thought of sharpening any blade. There seems to be a lack of information on the subject. Jeff Acord Belgrade, Montana I've never sharpened a leatherworking tool so I'm not sure how sharp it has to be. That said, when I sharpen any odd-shaped tool for woodworking, I tend to avoid my sharpening stones. Instead, I'll secure the tool in a handscrew and clamp the handscrew in my bench vise. Then I work the edge with sanding fids — essentially curved scraps of wood with adhesive-back sandpaper stuck to them. For a tool with a convex blade, such as a moulding plane, I'll make a cut using the tool in some softwood. Then I'll stick some sandpaper to the shape and work the edge. For curved knifelike tools, I'll trace a section of the curvature on a scrap, band saw out the shape, smooth it with a rasp and then stick the sandpaper to that. Move up in grits until you get to the level of sharpness you require — not everything needs to be as sharp as a plane iron. For sharpening marking knives, for example, I'll start with #150 grit and progress up to about #300 grit. That's good enough to sever wood fibers cleanly. For sharpening concave blades (such as an inshave), you can use a large dowel wrapped in sandpaper in a similar manner. — Christopher Schwarz, executive editor How Can I Make Small Patches For Repairing Veneer? I recently purchased a coffee table that has some age on it. It has a veneered top and someone has made an attempt to replace a small area. It is a very bad attempt. I have some walnut that's more than 100 years old that would match up well. The prob-continued on page 16 14 Popular Woodworking June 2005 |