Popular Woodworking 2005-10 № 150, страница 45

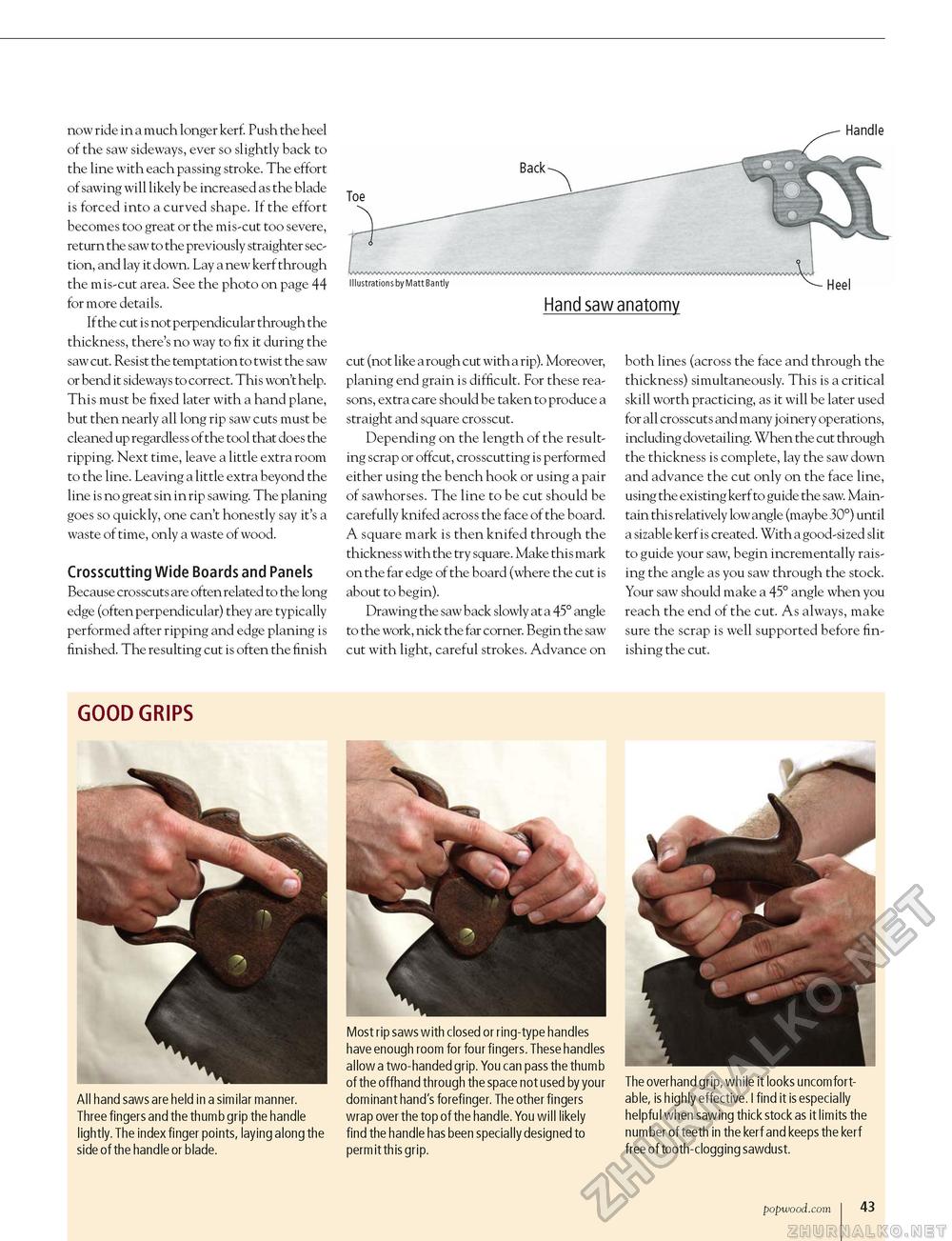

Handle Illustrations by Matt Bantly Heel Hand saw anatomy now ride in a much longer kerf. Push the heel of the saw sideways, ever so slightly back to the line with each passing stroke. The effort of sawing will likely be increased as the blade is forced into a curved shape. If the effort becomes too great or the mis-cut too severe, return the saw to the previously straighter section, and lay it down. Lay a new kerf through the mis-cut area. See the photo on page 44 for more details. If the cut is not perpendicular through the thickness, there's no way to fix it during the saw cut. Resist the temptation to twist the saw or bend it sideways to correct. This won't help. This must be fixed later with a hand plane, but then nearly all long rip saw cuts must be cleaned up regardless of the tool that does the ripping. Next time, leave a little extra room to the line. Leaving a little extra beyond the line is no great sin in rip sawing. The planing goes so quickly, one can't honestly say it's a waste of time, only a waste of wood. Crosscutting Wide Boards and Panels Because crosscuts are often related to the long edge (often perpendicular) they are typically performed after ripping and edge planing is finished. The resulting cut is often the finish cut (not like a rough cut with a rip). Moreover, planing end grain is difficult. For these reasons, extra care should be taken to produce a straight and square crosscut. Depending on the length of the resulting scrap or offcut, crosscutting is performed either using the bench hook or using a pair of sawhorses. The line to be cut should be carefully knifed across the face of the board. A square mark is then knifed through the thickness with the try square. Make this mark on the far edge of the board (where the cut is about to begin). Drawing the saw back slowly at a 45° angle to the work, nick the far corner. Begin the saw cut with light, careful strokes. Advance on both lines (across the face and through the thickness) simultaneously. This is a critical skill worth practicing, as it will be later used for all crosscuts and many joinery operations, including dovetailing. When the cut through the thickness is complete, lay the saw down and advance the cut only on the face line, using the existing kerf to guide the saw. Maintain this relatively low angle (maybe 30°) until a sizable kerf is created. With a good-sized slit to guide your saw, begin incrementally raising the angle as you saw through the stock. Your saw should make a 45° angle when you reach the end of the cut. As always, make sure the scrap is well supported before finishing the cut. GOOD GRIPS All hand saws are held in a similar manner. Three fingers and the thumb grip the handle lightly. The index finger points, laying along the side of the handle or blade. Most rip saws with closed or ring-type handles have enough room for four fingers. These handles allow a two-handed grip. You can pass the thumb of the offhand through the space not used by your dominant hand's forefinger. The other fingers wrap over the top of the handle. You will likely find the handle has been specially designed to permit this grip. The overhand grip, while it looks uncomfortable, is highly effective. I find it is especially helpful when sawing thick stock as it limits the number of teeth in the kerf and keeps the kerf free of tooth-clogging sawdust. popwood.com i 43 |