Popular Woodworking 2005-11 № 151, страница 32

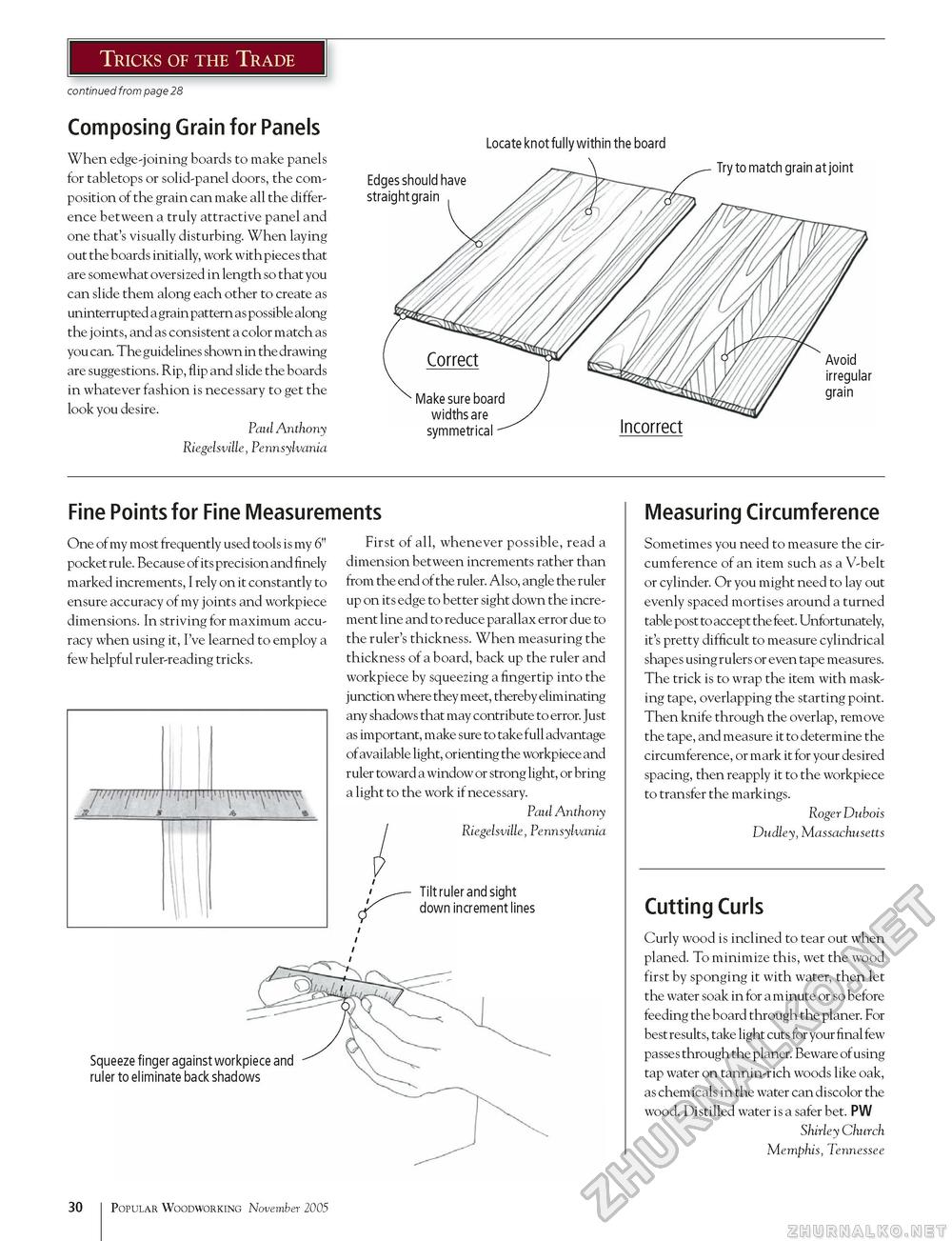

Tricks of the Trade continued from page 28 Composing Grain for Panels When edge-joining boards to make panels for tabletops or solid-panel doors, the composition of the grain can make all the difference between a truly attractive panel and one that's visually disturbing. When laying out the boards initially, work with pieces that are somewhat oversized in length so that you can slide them along each other to create as uninterrupted a grain pattern as possible along the joints, and as consistent a color match as you can. The guidelines shown in the drawing are suggestions. Rip, flip and slide the boards in whatever fashion is necessary to get the look you desire. Paul Anthony Riegelsville, Pennsylvania Edges should have straight grain Locate knot fully within the board Try to match grain at joint Make sure board widths are symmetrical Avoid irregular grain Fine Points for Fine Measurements One of my most frequently used tools is my 6" pocket rule. Because of its precision and finely marked increments, I rely on it constantly to ensure accuracy of my joints and workpiece dimensions. In striving for maximum accuracy when using it, I've learned to employ a few helpful ruler-reading tricks. First of all, whenever possible, read a dimension between increments rather than from the end of the ruler. Also, angle the ruler up on its edge to better sight down the increment line and to reduce parallax error due to the ruler's thickness. When measuring the thickness of a board, back up the ruler and workpiece by squeezing a fingertip into the junction where they meet, thereby eliminating any shadows that may contribute to error. Just as important, make sure to take full advantage of available light, orienting the workpiece and ruler toward a window or strong light, or bring a light to the work if necessary. Paul Anthony Riegelsville, Pennsylvania Tilt ruler and sight down increment lines Squeeze finger against workpiece and ruler to eliminate back shadows Measuring Circumference Sometimes you need to measure the circumference of an item such as a V-belt or cylinder. Or you might need to lay out evenly spaced mortises around a turned table post to accept the feet. Unfortunately, it's pretty difficult to measure cylindrical shapes using rulers or even tape measures. The trick is to wrap the item with masking tape, overlapping the starting point. Then knife through the overlap, remove the tape, and measure it to determine the circumference, or mark it for your desired spacing, then reapply it to the workpiece to transfer the markings. Roger Dubois Dudley, Massachusetts Cutting Curls Curly wood is inclined to tear out when planed. To minimize this, wet the wood first by sponging it with water, then let the water soak in for a minute or so before feeding the board through the planer. For best results, take light cuts for your final few passes through the planer. Beware of using tap water on tannin-rich woods like oak, as chemicals in the water can discolor the wood. Distilled water is a safer bet. PW Shirley Church Memphis, Tennessee 30 Popular Woodworking November 2005 |