Popular Woodworking 2005-12 № 152, страница 26

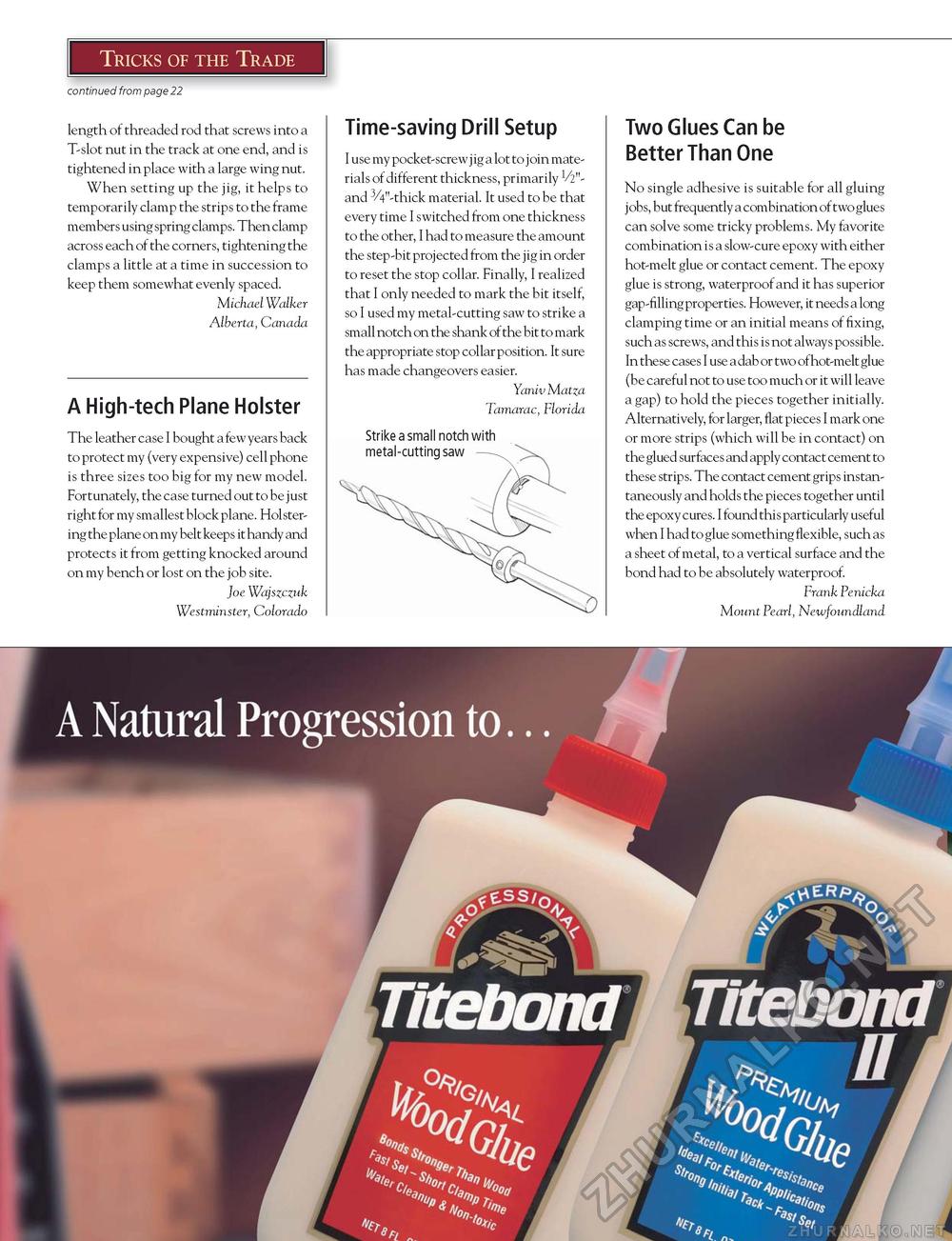

Tricks of the Trade continued from page 22 length of threaded rod that screws into a T-slot nut in the track at one end, and is tightened in place with a large wing nut. When setting up the jig, it helps to temporarily clamp the strips to the frame members using spring clamps. Then clamp across each of the corners, tightening the clamps a little at a time in succession to keep them somewhat evenly spaced. Michael Walker Alberta, Canada A High-tech Plane Holster The leather case I bought a few years back to protect my (very expensive) cell phone is three sizes too big for my new model. Fortunately, the case turned out to be just right for my smallest block plane. Holster-ing the plane on my belt keeps it handy and protects it from getting knocked around on my bench or lost on the job site. Joe Wajszczuk Westminster, Colorado Time-saving Drill Setup I use my pocket-scre w j ig a lot to j oin materials of different thickness, primarily V2"-and 3/4"-thick material. It used to be that every time I switched from one thickness to the other, I had to measure the amount the step-bit projected from the jig in order to reset the stop collar. Finally, I realized that I only needed to mark the bit itself, so I used my metal-cutting saw to strike a small notch on the shank of the bit to mark the appropriate stop collar position. It sure has made changeovers easier. Yaniv Matza Tamarac, Florida Strike a small notch with metal-cutting saw Two Glues Can be Better Than One No single adhesive is suitable for all gluing jobs, but frequently a combination of two glues can solve some tricky problems. My favorite combination is a slow-cure epoxy with either hot-melt glue or contact cement. The epoxy glue is strong, waterproof and it has superior gap-filling properties. However, it needs a long clamping time or an initial means of fixing, such as screws, and this is not always possible. In these cases I use a dab or two ofhot-melt glue (be careful not to use too much or it will leave a gap) to hold the pieces together initially. Alternatively, for larger, flat pieces I mark one or more strips (which will be in contact) on the glued surfaces and apply contact cement to these strips. The contact cement grips instantaneously and holds the pieces together until the epoxy cures. I found this particularly useful when I had to glue something flexible, such as a sheet of metal, to a vertical surface and the bond had to be absolutely waterproof. Frank Penicka Mount Pearl, Newfoundland |