Popular Woodworking 2005-12 № 152, страница 48

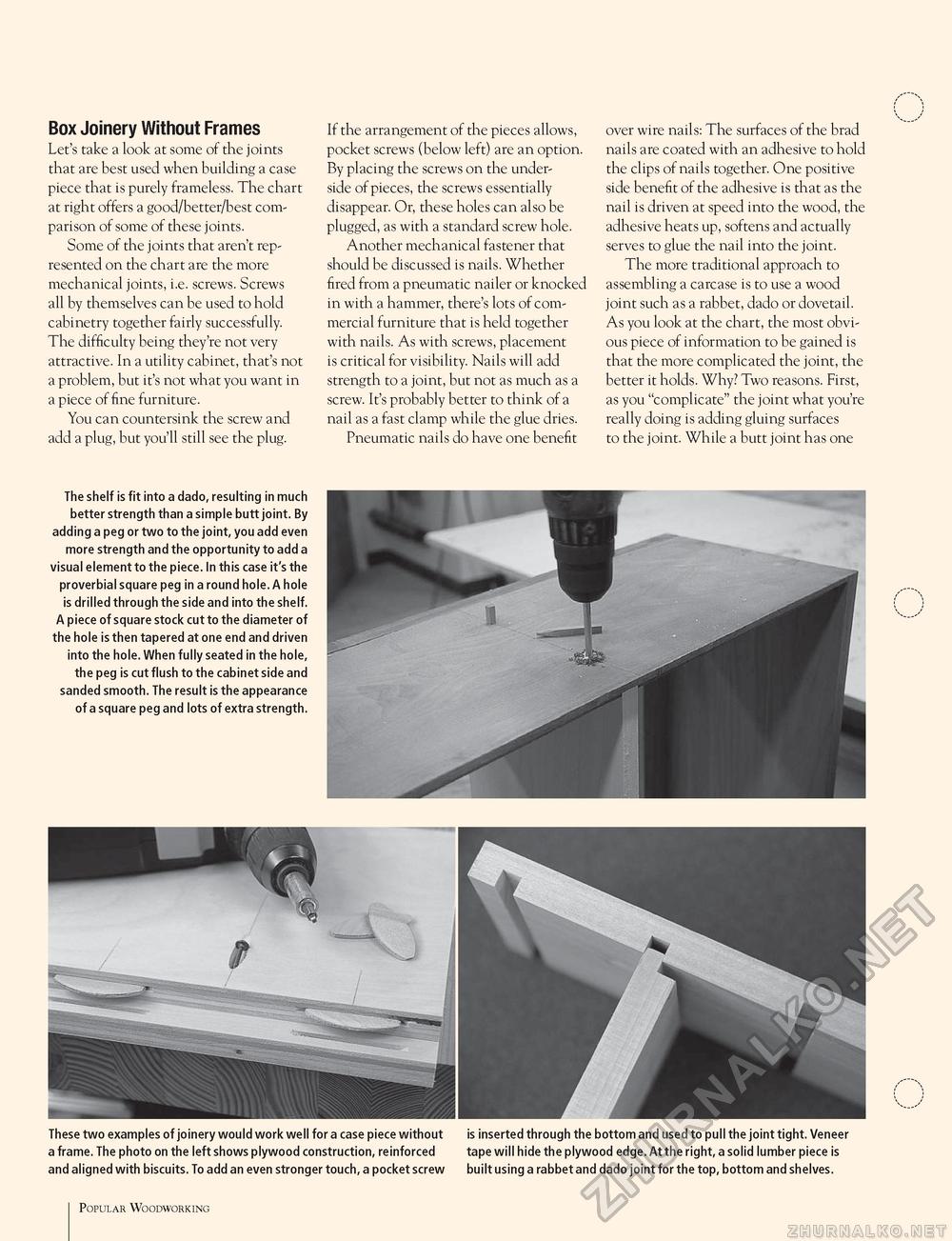

Box Joinery Without Frames Let's take a look at some of the joints that are best used when building a case piece that is purely frameless. The chart at right offers a good/better/best comparison of some of these joints. Some of the joints that aren't represented on the chart are the more mechanical joints, i.e. screws. Screws all by themselves can be used to hold cabinetry together fairly successfully. The difficulty being they're not very attractive. In a utility cabinet, that's not a problem, but it's not what you want in a piece of fine furniture. You can countersink the screw and add a plug, but you'll still see the plug. The shelf is fit into a dado, resulting in much better strength than a simple butt joint. By adding a peg or two to the joint, you add even more strength and the opportunity to add a visual element to the piece. In this case it's the proverbial square peg in a round hole. A hole is drilled through the side and into the shelf. A piece of square stock cut to the diameter of the hole is then tapered at one end and driven into the hole. When fully seated in the hole, the peg is cut flush to the cabinet side and sanded smooth. The result is the appearance of a square peg and lots of extra strength. If the arrangement of the pieces allows, pocket screws (below left) are an option. By placing the screws on the underside of pieces, the screws essentially disappear. Or, these holes can also be plugged, as with a standard screw hole. Another mechanical fastener that should be discussed is nails. Whether fired from a pneumatic nailer or knocked in with a hammer, there's lots of commercial furniture that is held together with nails. As with screws, placement is critical for visibility. Nails will add strength to a joint, but not as much as a screw. It's probably better to think of a nail as a fast clamp while the glue dries. Pneumatic nails do have one benefit over wire nails: The surfaces of the brad nails are coated with an adhesive to hold the clips of nails together. One positive side benefit of the adhesive is that as the nail is driven at speed into the wood, the adhesive heats up, softens and actually serves to glue the nail into the joint. The more traditional approach to assembling a carcase is to use a wood joint such as a rabbet, dado or dovetail. As you look at the chart, the most obvious piece of information to be gained is that the more complicated the joint, the better it holds. Why? Two reasons. First, as you "complicate" the joint what you're really doing is adding gluing surfaces to the joint. While a butt joint has one These two examples of joinery would work well for a case piece without is inserted through the bottom and used to pull the joint tight. Veneer a frame. The photo on the left shows plywood construction, reinforced tape will hide the plywood edge. At the right, a solid lumber piece is and aligned with biscuits. To add an even stronger touch, a pocket screw built using a rabbet and dado joint for the top, bottom and shelves. popularwoodworking.com 33 |