Popular Woodworking 2005-12 № 152, страница 50

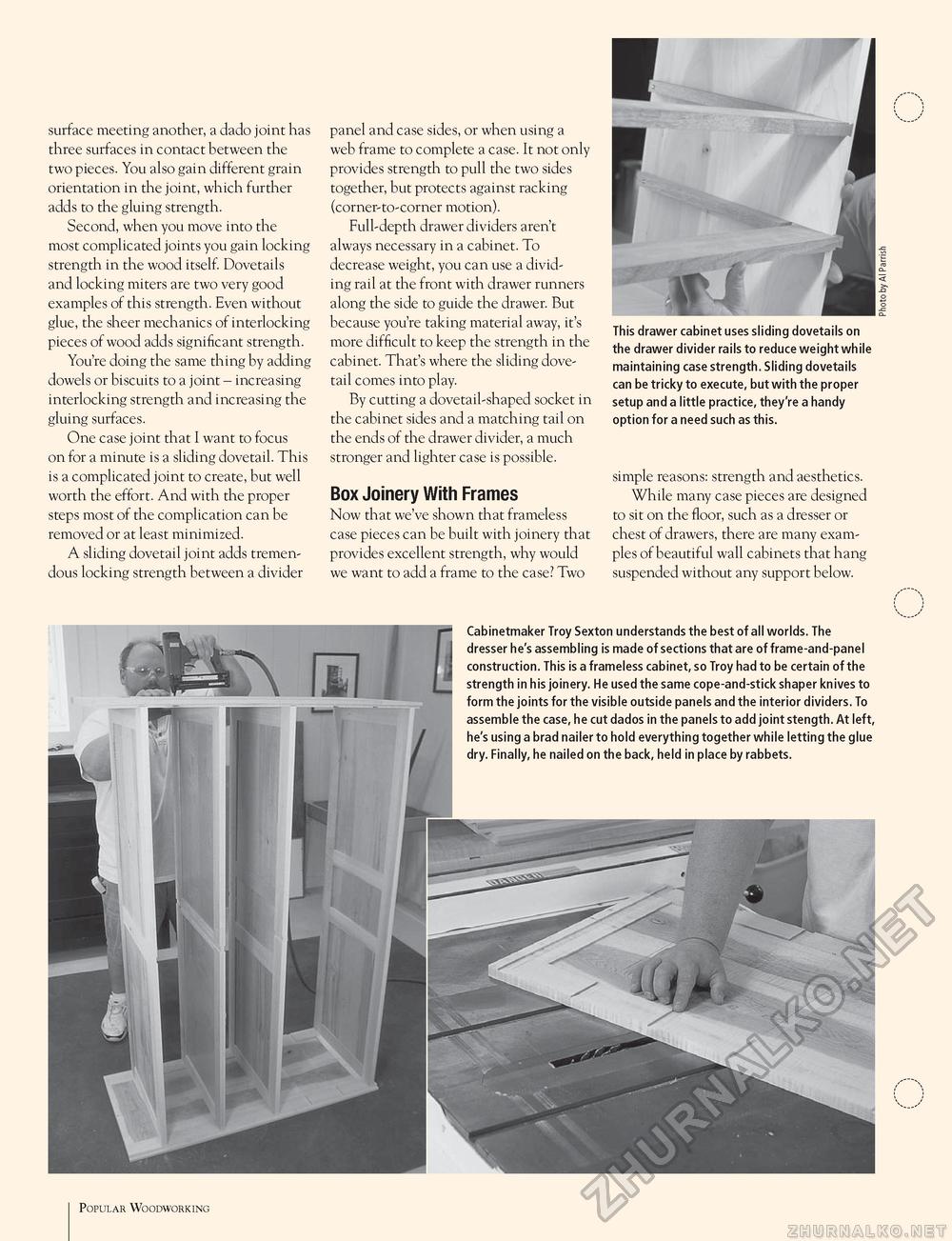

surface meeting another, a dado joint has three surfaces in contact between the two pieces. You also gain different grain orientation in the joint, which further adds to the gluing strength. Second, when you move into the most complicated joints you gain locking strength in the wood itself. Dovetails and locking miters are two very good examples of this strength. Even without glue, the sheer mechanics of interlocking pieces of wood adds significant strength. You're doing the same thing by adding dowels or biscuits to a joint - increasing interlocking strength and increasing the gluing surfaces. One case joint that I want to focus on for a minute is a sliding dovetail. This is a complicated joint to create, but well worth the effort. And with the proper steps most of the complication can be removed or at least minimized. A sliding dovetail joint adds tremendous locking strength between a divider panel and case sides, or when using a web frame to complete a case. It not only provides strength to pull the two sides together, but protects against racking (corner-to-corner motion). Full-depth drawer dividers aren't always necessary in a cabinet. To decrease weight, you can use a dividing rail at the front with drawer runners along the side to guide the drawer. But because you're taking material away, it's more difficult to keep the strength in the cabinet. That's where the sliding dovetail comes into play. By cutting a dovetail-shaped socket in the cabinet sides and a matching tail on the ends of the drawer divider, a much stronger and lighter case is possible. Box Joinery With Frames Now that we've shown that frameless case pieces can be built with joinery that provides excellent strength, why would we want to add a frame to the case? Two This drawer cabinet uses sliding dovetails on the drawer divider rails to reduce weight while maintaining case strength. Sliding dovetails can be tricky to execute, but with the proper setup and a little practice, they're a handy option for a need such as this. simple reasons: strength and aesthetics. While many case pieces are designed to sit on the floor, such as a dresser or chest of drawers, there are many examples of beautiful wall cabinets that hang suspended without any support below. Cabinetmaker Troy Sexton understands the best of all worlds. The dresser he's assembling is made of sections that are of frame-and-panel construction. This is a frameless cabinet, so Troy had to be certain of the strength in his joinery. He used the same cope-and-stick shaper knives to form the joints for the visible outside panels and the interior dividers. To assemble the case, he cut dados in the panels to add joint stength. At left, he's using a brad nailer to hold everything together while letting the glue dry. Finally, he nailed on the back, held in place by rabbets. Popular Woodworking |