Popular Woodworking 2005-12 № 152, страница 57

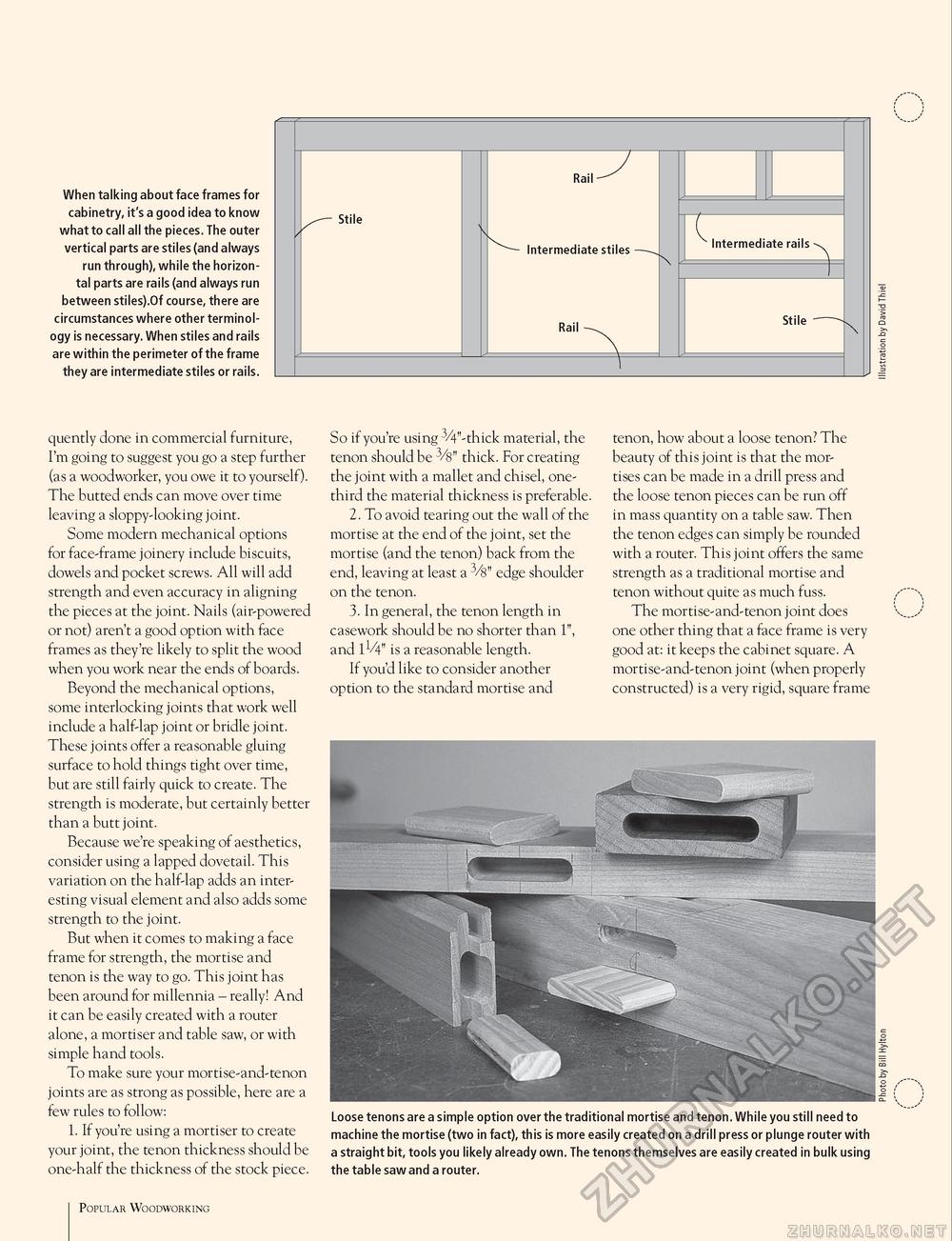

When talking about face frames for cabinetry, it's a good idea to know what to call all the pieces. The outer vertical parts are stiles (and always run through), while the horizontal parts are rails (and always run between stiles).Of course, there are circumstances where other terminology is necessary. When stiles and rails are within the perimeter of the frame they are intermediate stiles or rails. Stile Rail - Intermediate stiles Rail Intermediate rails Stile quently done in commercial furniture, I'm going to suggest you go a step further (as a woodworker, you owe it to yourself). The butted ends can move over time leaving a sloppy-looking joint. Some modern mechanical options for face-frame joinery include biscuits, dowels and pocket screws. All will add strength and even accuracy in aligning the pieces at the joint. Nails (air-powered or not) aren't a good option with face frames as they're likely to split the wood when you work near the ends of boards. Beyond the mechanical options, some interlocking joints that work well include a half-lap joint or bridle joint. These joints offer a reasonable gluing surface to hold things tight over time, but are still fairly quick to create. The strength is moderate, but certainly better than a butt joint. Because we're speaking of aesthetics, consider using a lapped dovetail. This variation on the half-lap adds an interesting visual element and also adds some strength to the joint. But when it comes to making a face frame for strength, the mortise and tenon is the way to go. This joint has been around for millennia - really! And it can be easily created with a router alone, a mortiser and table saw, or with simple hand tools. To make sure your mortise-and-tenon joints are as strong as possible, here are a few rules to follow: 1. If you're using a mortiser to create your joint, the tenon thickness should be one-half the thickness of the stock piece. So if you're using 3/4"-thick material, the tenon should be 3/8" thick. For creating the joint with a mallet and chisel, one-third the material thickness is preferable. 2. To avoid tearing out the wall of the mortise at the end of the joint, set the mortise (and the tenon) back from the end, leaving at least a 3/8" edge shoulder on the tenon. 3. In general, the tenon length in casework should be no shorter than 1", and M" is a reasonable length. If you'd like to consider another option to the standard mortise and tenon, how about a loose tenon? The beauty of this joint is that the mortises can be made in a drill press and the loose tenon pieces can be run off in mass quantity on a table saw. Then the tenon edges can simply be rounded with a router. This joint offers the same strength as a traditional mortise and tenon without quite as much fuss. The mortise-and-tenon joint does one other thing that a face frame is very good at: it keeps the cabinet square. A mortise-and-tenon joint (when properly constructed) is a very rigid, square frame Loose tenons are a simple option over the traditional mortise and tenon. While you still need to machine the mortise (two in fact), this is more easily created on a drill press or plunge router with a straight bit, tools you likely already own. The tenons themselves are easily created in bulk using the table saw and a router. Popular Woodworking |