Popular Woodworking 2005-12 № 152, страница 59

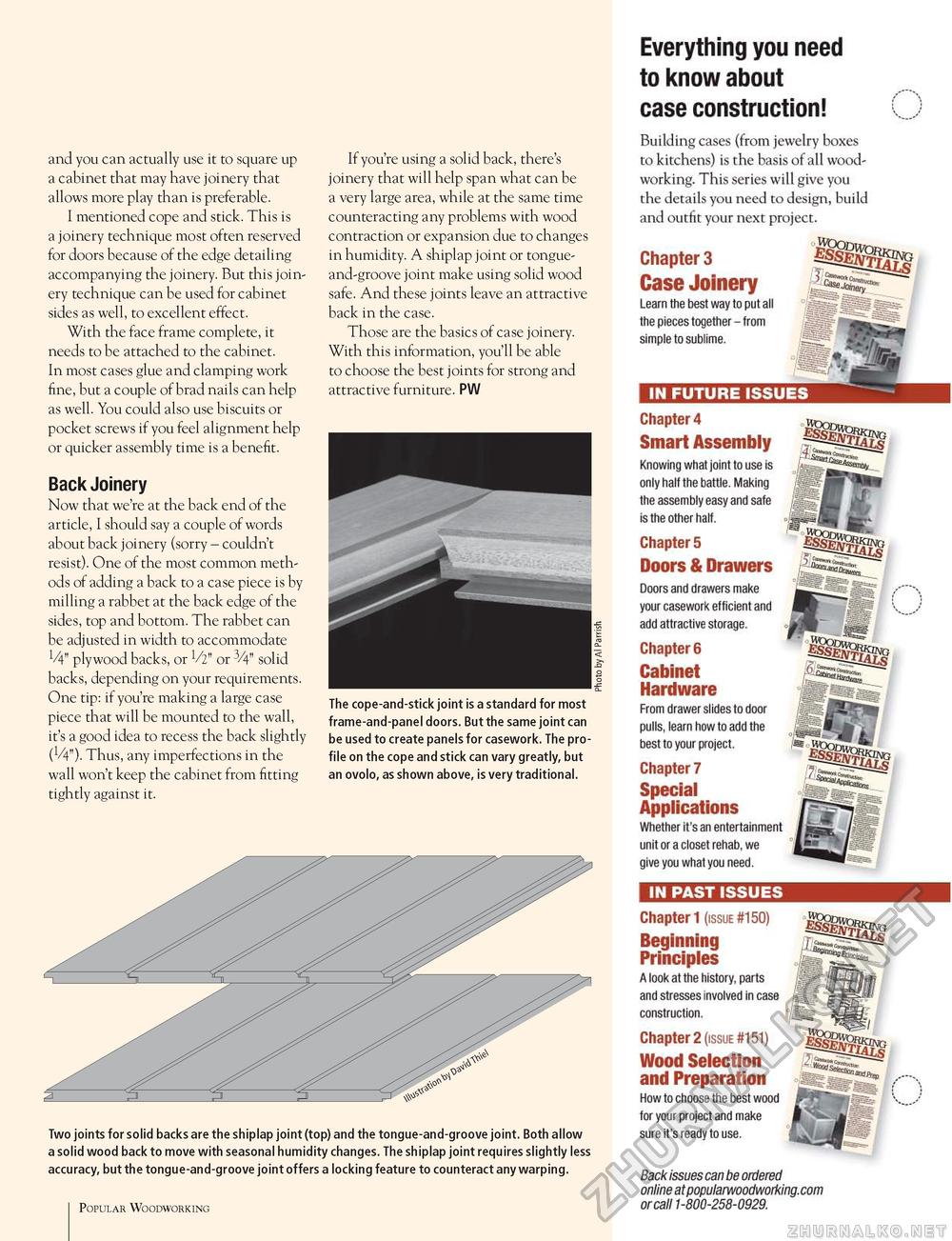

and you can actually use it to square up a cabinet that may have joinery that allows more play than is preferable. I mentioned cope and stick. This is a joinery technique most often reserved for doors because of the edge detailing accompanying the joinery. But this joinery technique can be used for cabinet sides as well, to excellent effect. With the face frame complete, it needs to be attached to the cabinet. In most cases glue and clamping work fine, but a couple of brad nails can help as well. You could also use biscuits or pocket screws if you feel alignment help or quicker assembly time is a benefit. Back Joinery Now that we're at the back end of the article, I should say a couple of words about back joinery (sorry - couldn't resist). One of the most common methods of adding a back to a case piece is by milling a rabbet at the back edge of the sides, top and bottom. The rabbet can be adjusted in width to accommodate M-" plywood backs, or 1/2" or 3/4" solid backs, depending on your requirements. One tip: if you're making a large case piece that will be mounted to the wall, it's a good idea to recess the back slightly (1/4"). Thus, any imperfections in the wall won't keep the cabinet from fitting tightly against it. If you're using a solid back, there's joinery that will help span what can be a very large area, while at the same time counteracting any problems with wood contraction or expansion due to changes in humidity. A shiplap joint or tongue-and-groove joint make using solid wood safe. And these joints leave an attractive back in the case. Those are the basics of case joinery. With this information, you'll be able to choose the best joints for strong and attractive furniture. PW The cope-and-stick joint is a standard for most frame-and-panel doors. But the same joint can be used to create panels for casework. The profile on the cope and stick can vary greatly, but an ovolo, as shown above, is very traditional. Two joints for solid backs are the shiplap joint (top) and the tongue-and-groove joint. Both allow a solid wood back to move with seasonal humidity changes. The shiplap joint requires slightly less accuracy, but the tongue-and-groove joint offers a locking feature to counteract any warping. Popular Woodworking |