Popular Woodworking 2006-02 № 153, страница 24

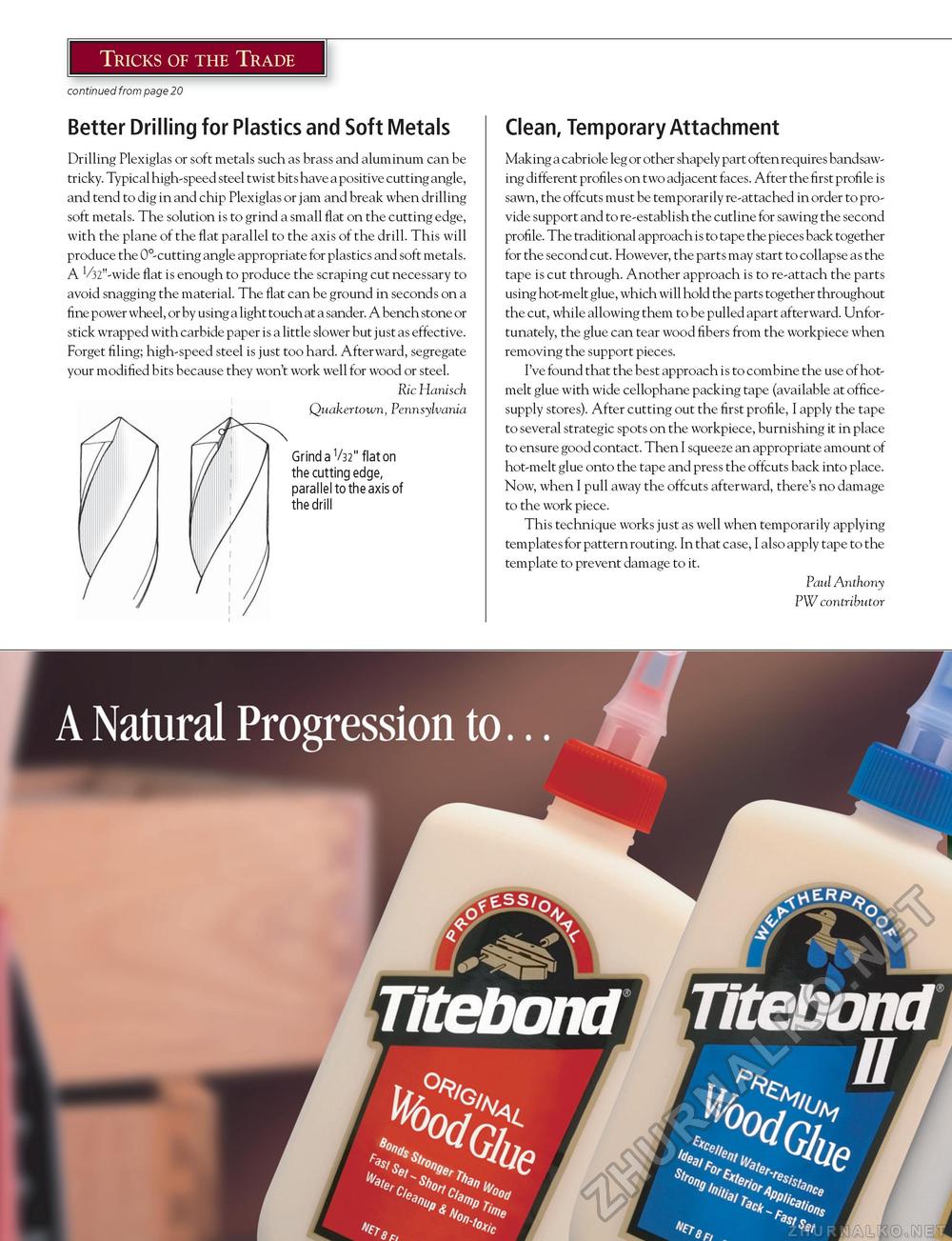

Tricks of the Trade continued from page 20 Better Drilling for Plastics and Soft Metals Drilling Plexiglas or soft metals such as brass and aluminum can be tricky. Typical high-speed steel twist bits have a positive cutting angle, and tend to dig in and chip Plexiglas or j am and break when drilling soft metals. The solution is to grind a small flat on the cutting edge, with the plane of the flat parallel to the axis of the drill. This will produce the 0°-cutting angle appropriate for plastics and soft metals. A V32"-wide flat is enough to produce the scraping cut necessary to avoid snagging the material. The flat can be ground in seconds on a fine power wheel, or by using a light touch at a sander. A bench stone or stick wrapped with carbide paper is a little slower but just as effective. Forget filing; high-speed steel is just too hard. Afterward, segregate your modified bits because they won't work well for wood or steel. Ric Hanisch Quakertown, Pennsylvania Grind a V32" flat on the cutting edge, parallel to the axis of the drill Clean, Temporary Attachment Making a cabriole leg or other shapely part often requires bandsaw-ing different profiles on two adjacent faces. After the first profile is sawn, the offcuts must be temporarily re-attached in order to provide support and to re-establish the cutline for sawing the second profile. The traditional approach is to tape the pieces back together for the second cut. However, the parts may start to collapse as the tape is cut through. Another approach is to re-attach the parts using hot-melt glue, which will hold the parts together throughout the cut, while allowing them to be pulled apart afterward. Unfortunately, the glue can tear wood fibers from the workpiece when removing the support pieces. I've found that the best approach is to combine the use of hot-melt glue with wide cellophane packing tape (available at office-supply stores). After cutting out the first profile, I apply the tape to several strategic spots on the workpiece, burnishing it in place to ensure good contact. Then I squeeze an appropriate amount of hot-melt glue onto the tape and press the offcuts back into place. Now, when I pull away the offcuts afterward, there's no damage to the work piece. This technique works just as well when temporarily applying templates for pattern routing. In that case, I also apply tape to the template to prevent damage to it. Paul Anthony PW contributor |