Popular Woodworking 2006-04 № 154, страница 50

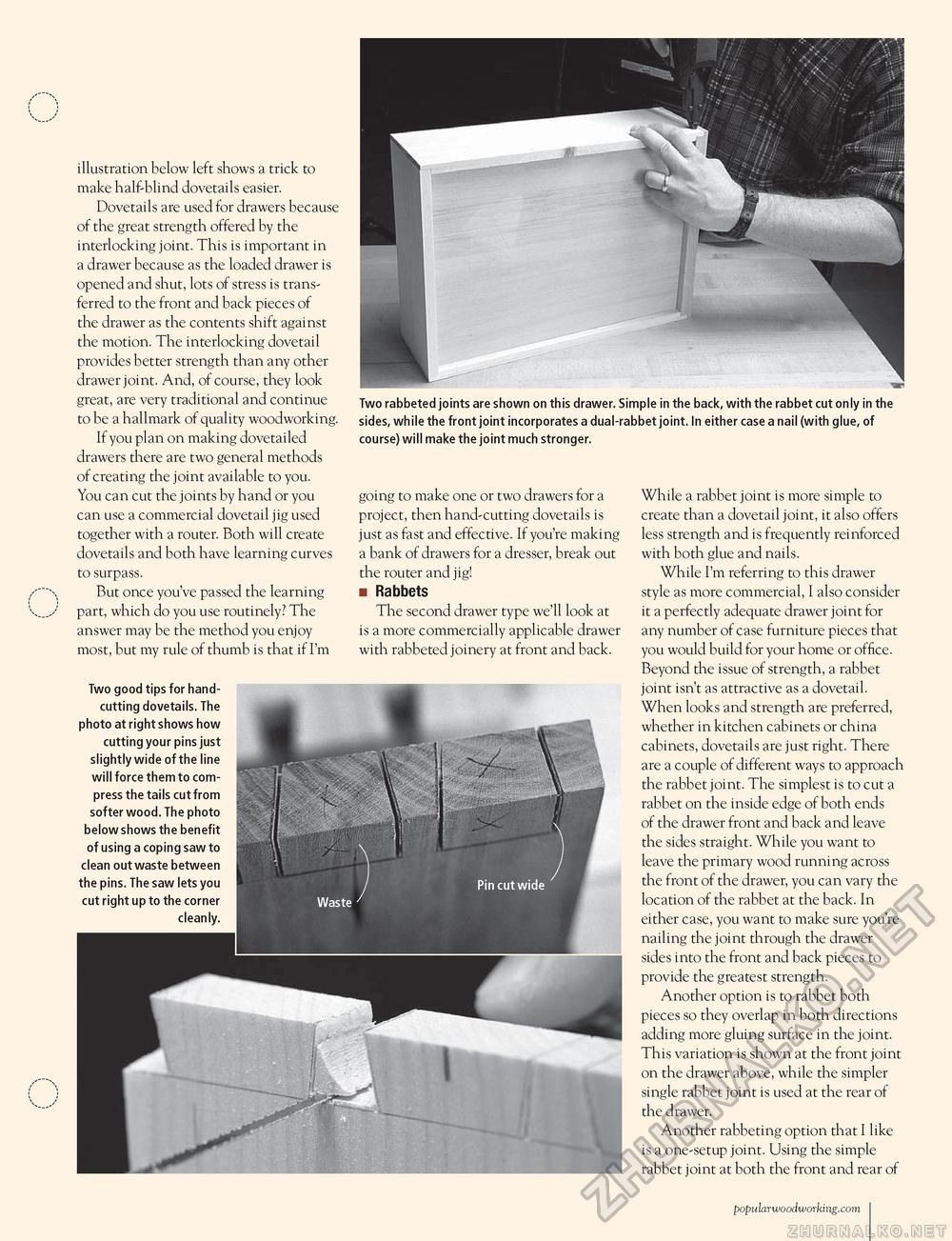

illustration below left shows a trick to make half-blind dovetails easier. Dovetails are used for drawers because of the great strength offered by the interlocking joint. This is important in a drawer because as the loaded drawer is opened and shut, lots of stress is transferred to the front and back pieces of the drawer as the contents shift against the motion. The interlocking dovetail provides better strength than any other drawer joint. And, of course, they look great, are very traditional and continue to be a hallmark of quality woodworking. If you plan on making dovetailed drawers there are two general methods of creating the joint available to you. You can cut the joints by hand or you can use a commercial dovetail jig used together with a router. Both will create dovetails and both have learning curves to surpass. But once you've passed the learning part, which do you use routinely? The answer may be the method you enjoy most, but my rule of thumb is that if I'm Two good tips for hand-cutting dovetails. The photo at right shows how cutting your pins just slightly wide of the line will force them to com press the tails cut from softer wood. The photo below shows the benefit of using a coping saw to clean out waste between the pins. The saw lets you cut right up to the corner cleanly. Two rabbeted joints are shown on this drawer. Simple in the back, with the rabbet cut only in the sides, while the front joint incorporates a dual-rabbet joint. In either case a nail (with glue, of course) will make the joint much stronger. going to make one or two drawers for a project, then hand-cutting dovetails is just as fast and effective. If you're making a bank of drawers for a dresser, break out the router and jig! ■ Rabbets The second drawer type we'll look at is a more commercially applicable drawer with rabbeted joinery at front and back. While a rabbet joint is more simple to create than a dovetail joint, it also offers less strength and is frequently reinforced with both glue and nails. While I'm referring to this drawer style as more commercial, I also consider it a perfectly adequate drawer joint for any number of case furniture pieces that you would build for your home or office. Beyond the issue of strength, a rabbet joint isn't as attractive as a dovetail. When looks and strength are preferred, whether in kitchen cabinets or china cabinets, dovetails are just right. There are a couple of different ways to approach the rabbet joint. The simplest is to cut a rabbet on the inside edge of both ends of the drawer front and back and leave the sides straight. While you want to leave the primary wood running across the front of the drawer, you can vary the location of the rabbet at the back. In either case, you want to make sure you're nailing the joint through the drawer sides into the front and back pieces to provide the greatest strength. Another option is to rabbet both pieces so they overlap in both directions adding more gluing surface in the joint. This variation is shown at the front joint on the drawer above, while the simpler single rabbet joint is used at the rear of the drawer. Another rabbeting option that I like is a one-setup joint. Using the simple rabbet joint at both the front and rear of popularwoodworking.com i 50 |