Popular Woodworking 2006-06 № 155, страница 18

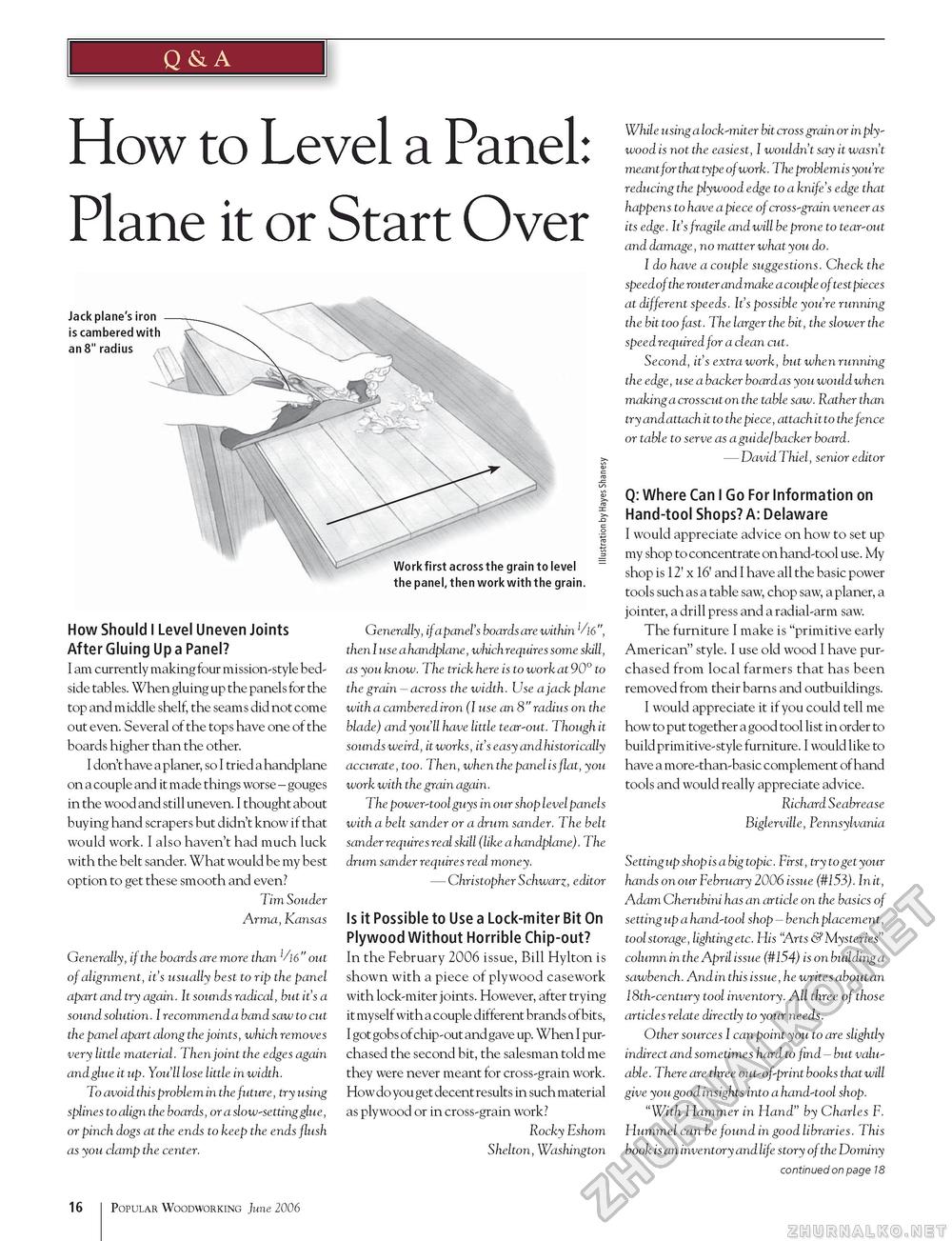

Q & A How to Level a Panel: Plane it or Start Over Jack plane's Iron Is cambered with an 8" radius How Should I Level Uneven Joints After Gluing Up a Panel? I am currently making four mission-style bedside tables. When gluing up the panels for the top and middle shelf, the seams did not come out even. Several of the tops have one of the boards higher than the other. I don't have a planer, so I tried a handplane on a couple and it made things worse - gouges in the wood and still uneven. I thought about buying hand scrapers but didn't know if that would work. I also haven't had much luck with the belt sander. What would be my best option to get these smooth and even? Tim Souder Arma, Kansas Generally, if the boards are more than 1/l6" out of alignment, it's usually best to rip the panel apart and try again. It sounds radical, but it's a sound solution. I recommend a band saw to cut the panel apart along the joints, which removes very little material. Then joint the edges again and glue it up. You'll lose little in width. To avoid this problem in the future, try using splines to align the boards, or a slow-setting glue, or pinch dogs at the ends to keep the ends flush as you clamp the center. Work first across the grain to level the panel, then work with the grain. Generally, if a panel's boards are within 116", then I use a handplane, which requires some skill, as you know. The trick here is to work at 90° to the grain — across the width. Use a jack plane with a cambered iron (I use an 8 " radius on the blade) and you'll have little tear-out. Though it sounds weird, it works, it's easy and historically accurate, too. Then, when the panel is flat, you work with the grain again. The power-tool guys in our shop level panels with a belt sander or a drum sander. The belt sander requires real skill (like a handplane). The drum sander requires real money. — Christopher Schwarz, editor Is it Possible to Use a Lock-miter Bit On Plywood Without Horrible Chip-out? In the February 2006 issue, Bill Hylton is shown with a piece of plywood casework with lock-miter joints. However, after trying it myself with a couple different brands of bits, I got gobs of chip-out and gave up. When I purchased the second bit, the salesman told me they were never meant for cross-grain work. How do you get decent results in such material as plywood or in cross-grain work? Rocky Eshom Shelton, Washington While using a lock-miter bit cross grain or in plywood is not the easiest, I wouldn't say it wasnt meant for that type of work. The problem is you're reducing the plywood edge to a knife's edge that happens to have a piece of cross-grain veneer as its edge. It's fragile and will be prone to tear-out and damage, no matter what you do. I do have a couple suggestions. Check the speed of the router and make a couple of test pieces at different speeds. It's possible you're running the bit too fast. The larger the bit, the slower the speed required for a clean cut. Second, it's extra work, but when running the edge, use a backer board as you would when making a crosscut on the table saw. Rather than try and attach it to the piece, attach it to the fence or table to serve as a guide/backer board. — David Thiel, senior editor Q: Where Can I Go For Information on Hand-tool Shops? A: Delaware I would appreciate advice on how to set up my shop to concentrate on hand-tool use. My shop is 12' x 16' and I have all the basic power tools such as a table saw, chop saw, a planer, a jointer, a drill press and a radial-arm saw. The furniture I make is "primitive early American" style. I use old wood I have purchased from local farmers that has been removed from their barns and outbuildings. I would appreciate it if you could tell me how to put together a good tool list in order to build primitive-style furniture. I would like to have a more-than-basic complement of hand tools and would really appreciate advice. Richard Seabrease Biglerville, Pennsylvania Setting up shop is a big topic. First, try to get your hands on our February 2006 issue (#153). In it, Adam Cherubini has an article on the basics of setting up a hand-tool shop — bench placement, tool storage, lighting etc. His "Arts & Mysteries" column in the April issue (#154) is on building a sawbench. And in this issue, he writes about an 18th-century tool inventory. All three of those articles relate directly to your needs. Other sources I can point you to are slightly indirect and sometimes hard to find — but valuable . There are three out-of-print books that will give you good insights into a hand-tool shop. "With Hammer in Hand" by Charles F. Hummel can be found in good libraries. This book is an inventory and life story of the Dominy continued on page 18 16 Popular Woodworking June 2006 |