Popular Woodworking 2006-10 № 157, страница 10

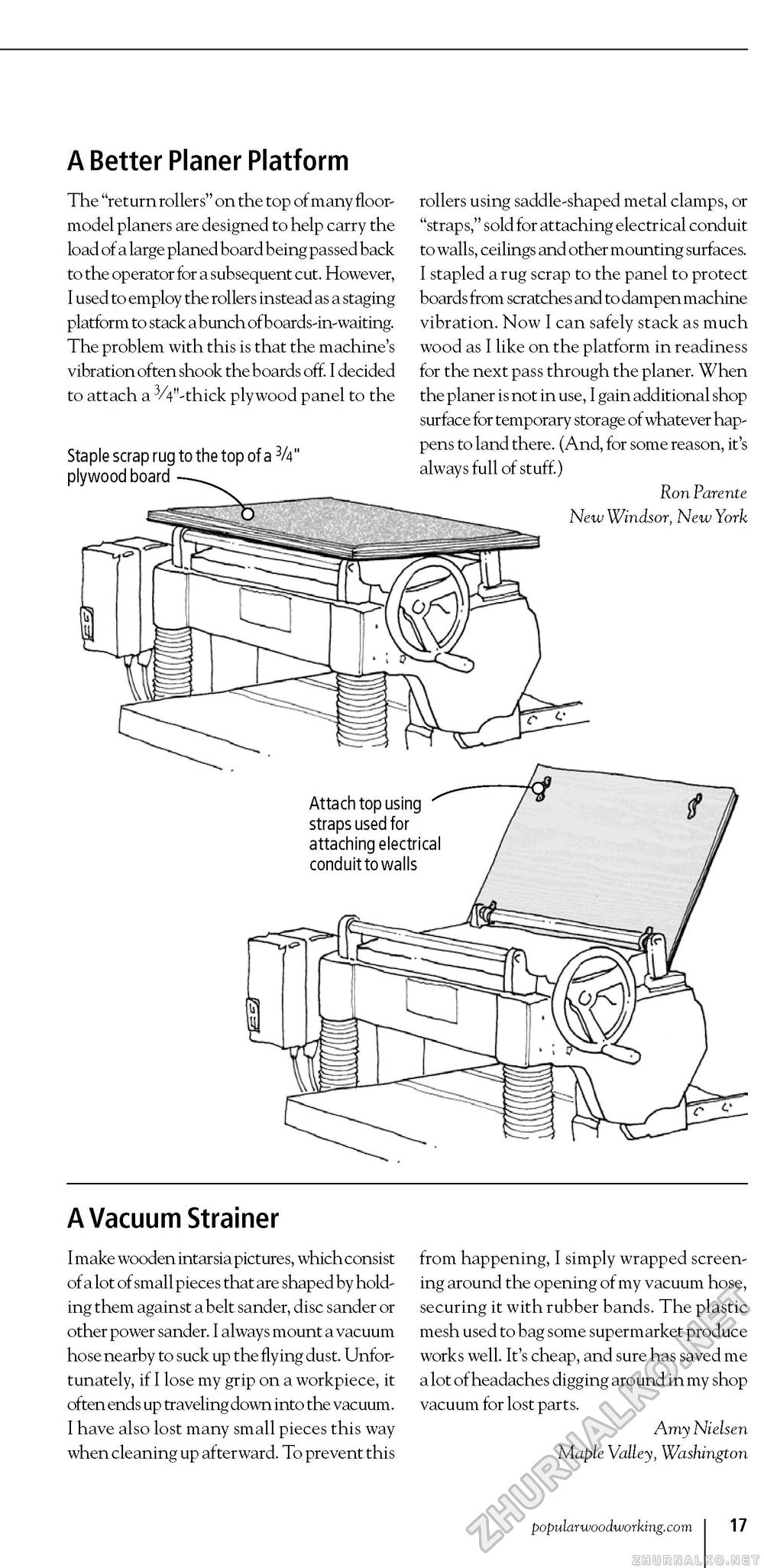

A Better Planer Platform The "return rollers" on the top of many floor-model planers are designed to help carry the load of a large planed board being passed back to the operator for a subsequent cut. However, I used to employ the rollers instead as a staging platform to stack a bunch of boards-in-waiting. The problem with this is that the machine's vibration often shook the boards off. I decided to attach a 3/4"-thick plywood panel to the Staple scrap rug to the top of a 3A" plywood board rollers using saddle-shaped metal clamps, or "straps," sold for attaching electrical conduit to walls, ceilings and other mounting surfaces. I stapled a rug scrap to the panel to protect boards from scratches and to dampen machine vibration. Now I can safely stack as much wood as I like on the platform in readiness for the next pass through the planer. When the planer is not in use, I gain additional shop surface for temporary storage of whatever happens to land there. (And, for some reason, it's always full of stuff.) Ron Parente New Windsor, New York Attach top using ^ straps used for attaching electrical conduit to walls A Vacuum Strainer I make wooden intarsia pictures, which consist of a lot of small pieces that are shaped by holding them against a belt sander, disc sander or other power sander. I always mount a vacuum hose nearby to suck up the flying dust. Unfortunately, if I lose my grip on a workpiece, it often ends up traveling down into the vacuum. I have also lost many small pieces this way when cleaning up afterward. To prevent this from happening, I simply wrapped screening around the opening of my vacuum hose, securing it with rubber bands. The plastic mesh used to bag some supermarket produce works well. It's cheap, and sure has saved me a lot of headaches digging around in my shop vacuum for lost parts. Amy Nielsen Maple Valley, Washington popularwoodworking.com i 17 |