Popular Woodworking 2006-10 № 157, страница 13

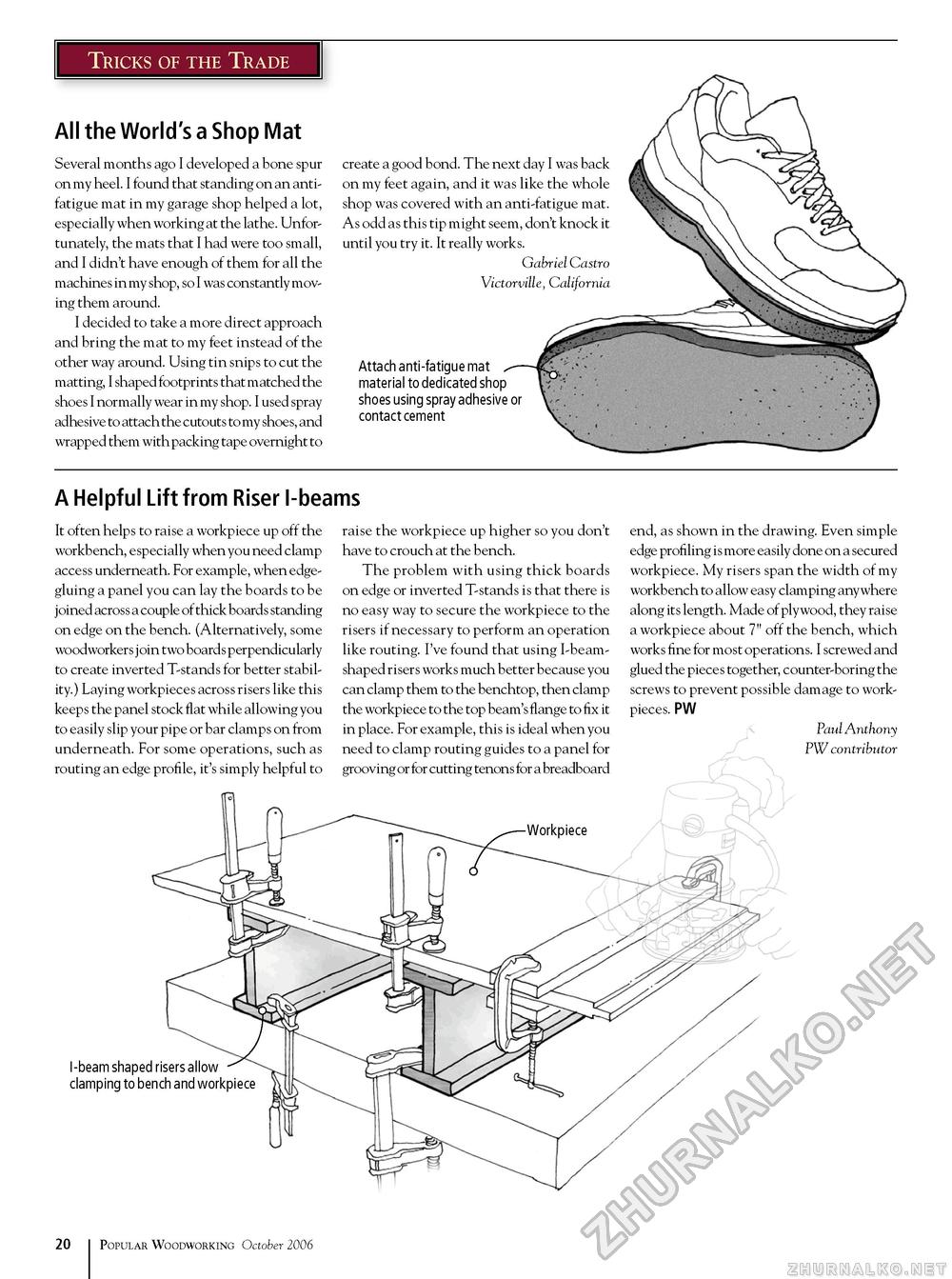

Tricks of the Trade All the World's a Shop Mat Several months ago I developed a bone spur on my heel. I found that standing on an anti-fatigue mat in my garage shop helped a lot, especially when working at the lathe. Unfortunately, the mats that I had were too small, and I didn't have enough of them for all the machines in my shop, so I was constantly moving them around. I decided to take a more direct approach and bring the mat to my feet instead of the other way around. Using tin snips to cut the matting, I shaped footprints that matched the shoes I normally wear in my shop. I used spray adhesive to attach the cutouts to my shoes, and wrapped them with packing tape overnight to create a good bond. The next day I was back on my feet again, and it was like the whole shop was covered with an anti-fatigue mat. As odd as this tip might seem, don't knock it until you try it. It really works. Gabriel Castro Victorville, California Attach anti-fatigue mat material to dedicated shop shoes using spray adhesive or contact cement A Helpful Lift from Riser I-beams It often helps to raise a workpiece up off the workbench, especially when you need clamp access underneath. For example, when edge-gluing a panel you can lay the boards to be joined across a couple of thick boards standing on edge on the bench. (Alternatively, some woodworkers join two boards perpendicularly to create inverted T-stands for better stability.) Laying workpieces across risers like this keeps the panel stock flat while allowing you to easily slip your pipe or bar clamps on from underneath. For some operations, such as routing an edge profile, it's simply helpful to raise the workpiece up higher so you don't have to crouch at the bench. The problem with using thick boards on edge or inverted T-stands is that there is no easy way to secure the workpiece to the risers if necessary to perform an operation like routing. I've found that using I-beam-shaped risers works much better because you can clamp them to the benchtop, then clamp the workpiece to the top beam's flange to fix it in place. For example, this is ideal when you need to clamp routing guides to a panel for grooving or for cutting tenons for a breadboard Workpiece end, as shown in the drawing. Even simple edge profiling is more easily done on a secured workpiece. My risers span the width of my workbench to allow easy clamping anywhere along its length. Made of plywood, they raise a workpiece about 7" off the bench, which works fine for most operations. I screwed and glued the pieces together, counter-boring the screws to prevent possible damage to work-pieces. PW Paul Anthony PW contribu tor I-beam shaped risers allow clamping to bench and workpiece 20 Popular Woodworking October 2006 |