Popular Woodworking 2006-10 № 157, страница 36

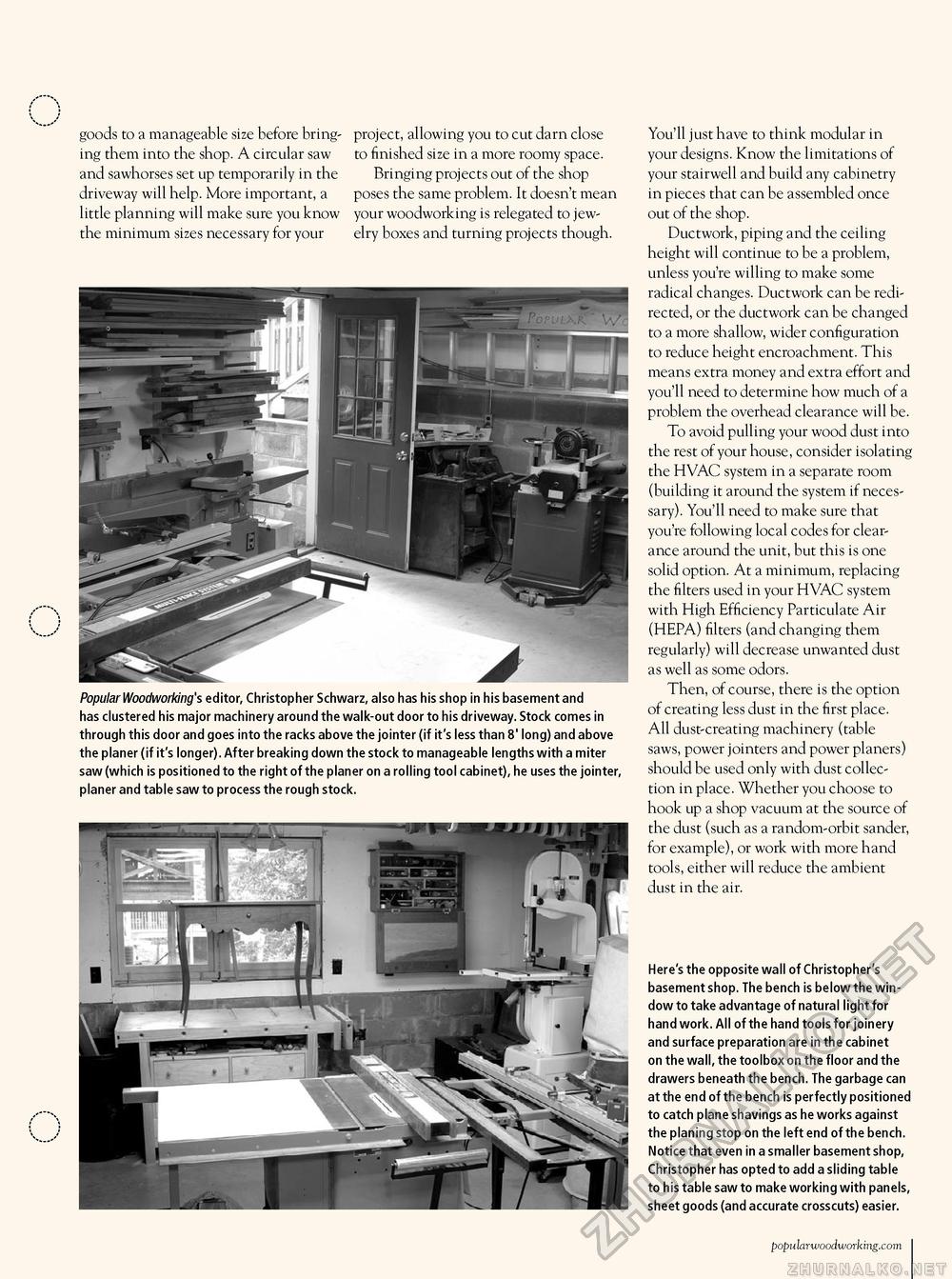

goods to a manageable size before bringing them into the shop. A circular saw and sawhorses set up temporarily in the driveway will help. More important, a little planning will make sure you know the minimum sizes necessary for your project, allowing you to cut darn close to finished size in a more roomy space. Bringing projects out of the shop poses the same problem. It doesn't mean your woodworking is relegated to jewelry boxes and turning projects though. Popular Woodworking's editor, Christopher Schwarz, also has his shop in his basement and has clustered his major machinery around the walk-out door to his driveway. Stock comes in through this door and goes into the racks above the jointer (if it's less than 8' long) and above the planer (if it's longer). After breaking down the stock to manageable lengths with a miter saw (which is positioned to the right of the planer on a rolling tool cabinet), he uses the jointer, planer and table saw to process the rough stock. You'll just have to think modular in your designs. Know the limitations of your stairwell and build any cabinetry in pieces that can be assembled once out of the shop. Ductwork, piping and the ceiling height will continue to be a problem, unless you're willing to make some radical changes. Ductwork can be redirected, or the ductwork can be changed to a more shallow, wider configuration to reduce height encroachment. This means extra money and extra effort and you'll need to determine how much of a problem the overhead clearance will be. To avoid pulling your wood dust into the rest of your house, consider isolating the HVAC system in a separate room (building it around the system if necessary). You'll need to make sure that you're following local codes for clearance around the unit, but this is one solid option. At a minimum, replacing the filters used in your HVAC system with High Efficiency Particulate Air (HEPA) filters (and changing them regularly) will decrease unwanted dust as well as some odors. Then, of course, there is the option of creating less dust in the first place. All dust-creating machinery (table saws, power jointers and power planers) should be used only with dust collection in place. Whether you choose to hook up a shop vacuum at the source of the dust (such as a random-orbit sander, for example), or work with more hand tools, either will reduce the ambient dust in the air. Here's the opposite wall of Christopher's basement shop. The bench is below the window to take advantage of natural light for hand work. All of the hand tools for joinery and surface preparation are in the cabinet on the wall, the toolbox on the floor and the drawers beneath the bench. The garbage can at the end of the bench is perfectly positioned to catch plane shavings as he works against the planing stop on the left end of the bench. Notice that even in a smaller basement shop, Christopher has opted to add a sliding table to his table saw to make working with panels, sheet goods (and accurate crosscuts) easier. popularwoodworking.com i 36 |