Popular Woodworking 2006-10 № 157, страница 72

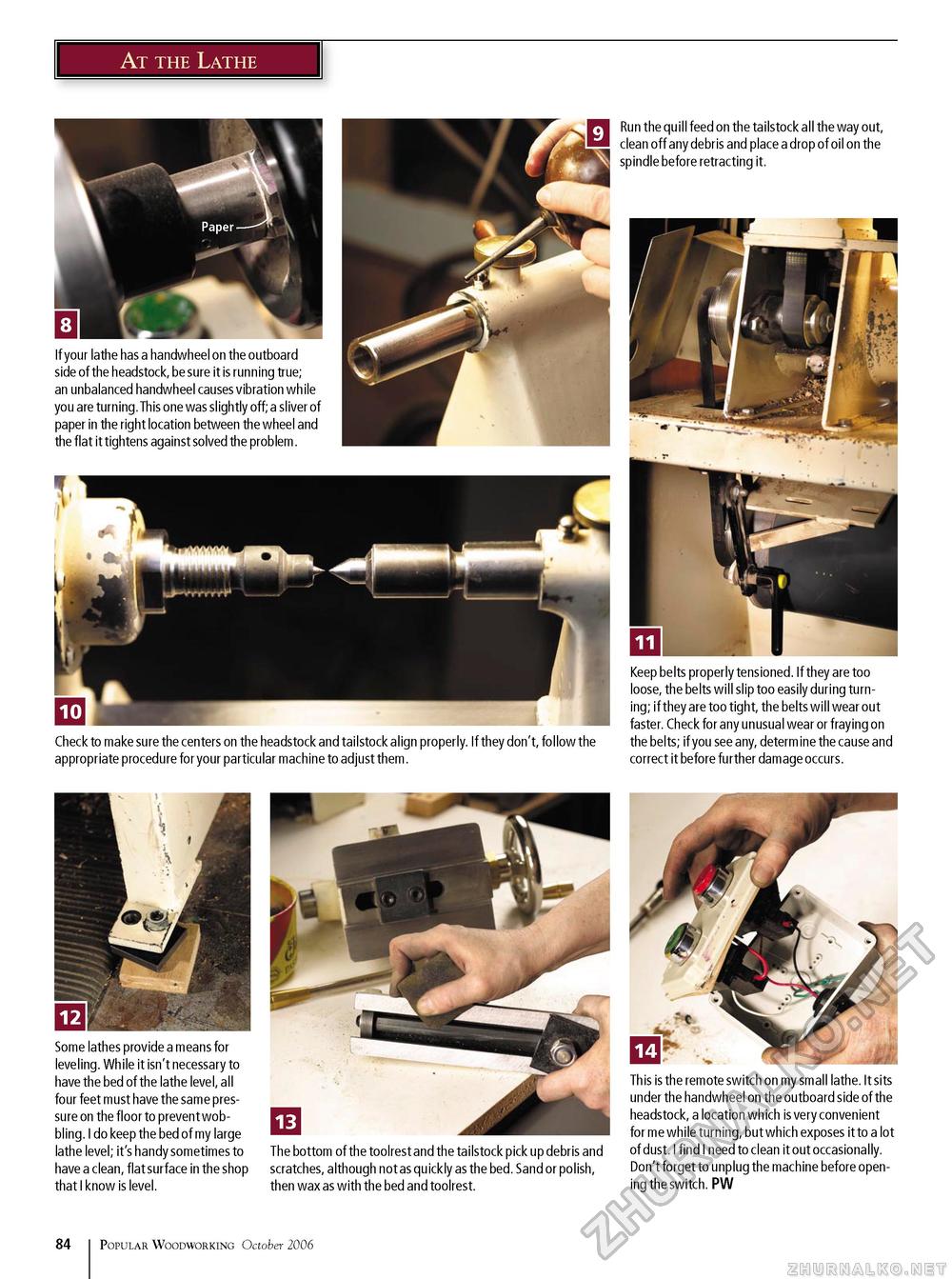

At the Lathe Run the quill feed on the tailstock all the way out, clean off any debris and place a drop of oil on the spindle before retracting it. Check to make sure the centers on the headstock and tailstock align properly. If they don't, follow the appropriate procedure for your particular machine to adjust them. Keep belts properly tensioned. If they are too loose, the belts will slip too easily during turning; if they are too tight, the belts will wear out faster. Check for any unusual wear or fraying on the belts; if you see any, determ ine the cause and correct it before further damage occurs. Some lathes provide a means for leveling. While it isn't necessary to have the bed of the lathe level, all four feet must have the same pressure on the floor to prevent wobbling. I do keep the bed of my large lathe level; it's handy sometimes to have a clean, flat surface in the shop that I know is level. The bottom of the toolrest and the tailstock pick up debris and scratches, although not as quickly as the bed. Sand or polish, then wax as with the bed and toolrest. This is the remote switch on my small lathe. It sits under the handwheel on the outboard side of the headstock, a location which is very convenient for me while turning, but which exposes it to a lot of dust. I find I need to clean it out occasionally. Don't forget to unplug the machine before opening the switch. PW 84 Popular Woodworking October 2006 |