Popular Woodworking 2006-11 № 158, страница 32

Common copper house wire

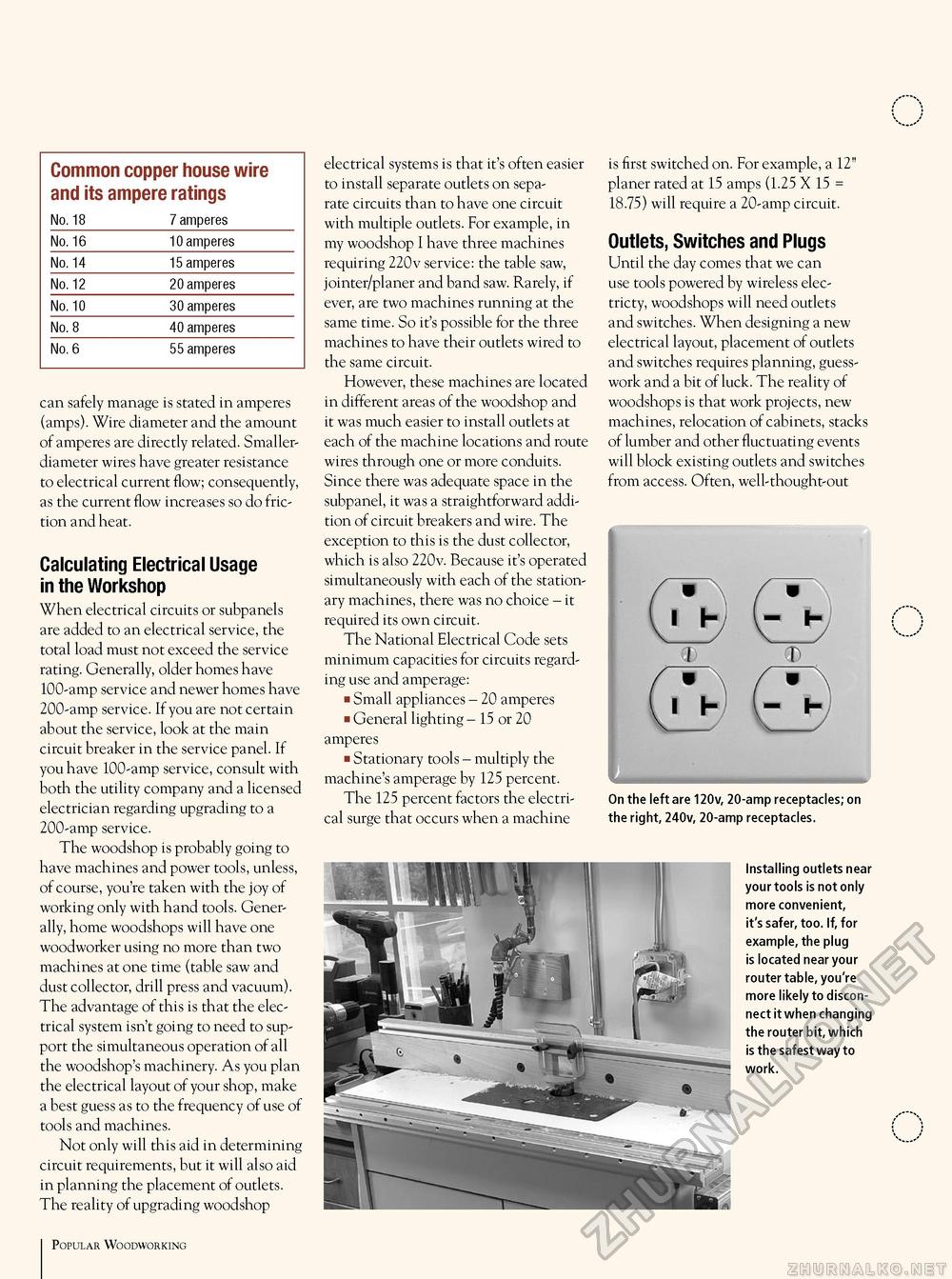

can safely manage is stated in amperes (amps). Wire diameter and the amount of amperes are directly related. Smaller-diameter wires have greater resistance to electrical current flow; consequently, as the current flow increases so do friction and heat. Calculating Electrical Usage in the Workshop When electrical circuits or subpanels are added to an electrical service, the total load must not exceed the service rating. Generally, older homes have 100-amp service and newer homes have 200-amp service. If you are not certain about the service, look at the main circuit breaker in the service panel. If you have 100-amp service, consult with both the utility company and a licensed electrician regarding upgrading to a 200-amp service. The woodshop is probably going to have machines and power tools, unless, of course, you're taken with the joy of working only with hand tools. Generally, home woodshops will have one woodworker using no more than two machines at one time (table saw and dust collector, drill press and vacuum). The advantage of this is that the electrical system isn't going to need to support the simultaneous operation of all the woodshop's machinery. As you plan the electrical layout of your shop, make a best guess as to the frequency of use of tools and machines. Not only will this aid in determining circuit requirements, but it will also aid in planning the placement of outlets. The reality of upgrading woodshop electrical systems is that it's often easier to install separate outlets on separate circuits than to have one circuit with multiple outlets. For example, in my woodshop I have three machines requiring 220v service: the table saw, jointer/planer and band saw. Rarely, if ever, are two machines running at the same time. So it's possible for the three machines to have their outlets wired to the same circuit. However, these machines are located in different areas of the woodshop and it was much easier to install outlets at each of the machine locations and route wires through one or more conduits. Since there was adequate space in the subpanel, it was a straightforward addition of circuit breakers and wire. The exception to this is the dust collector, which is also 220v. Because it's operated simultaneously with each of the stationary machines, there was no choice - it required its own circuit. The National Electrical Code sets minimum capacities for circuits regarding use and amperage: ■ Small appliances - 20 amperes ■ General lighting - 15 or 20 amperes ■ Stationary tools - multiply the machine's amperage by 125 percent. The 125 percent factors the electrical surge that occurs when a machine is first switched on. For example, a 12" planer rated at 15 amps (1.25 X 15 = 18.75) will require a 20-amp circuit. Outlets, Switches and Plugs Until the day comes that we can use tools powered by wireless elec-tricty, woodshops will need outlets and switches. When designing a new electrical layout, placement of outlets and switches requires planning, guesswork and a bit of luck. The reality of woodshops is that work projects, new machines, relocation of cabinets, stacks of lumber and other fluctuating events will block existing outlets and switches from access. Often, well-thought-out On the left are 120v, 20-amp receptacles; on the right, 240v, 20-amp receptacles. Installing outlets near your tools is not only more convenient, it's safer, too. If, for example, the plug is located near your router table, you're more likely to disconnect it when changing the router bit, which is the safest way to work. Popular Woodworking |

||||||||||||||||