Popular Woodworking 2006-11 № 158, страница 33

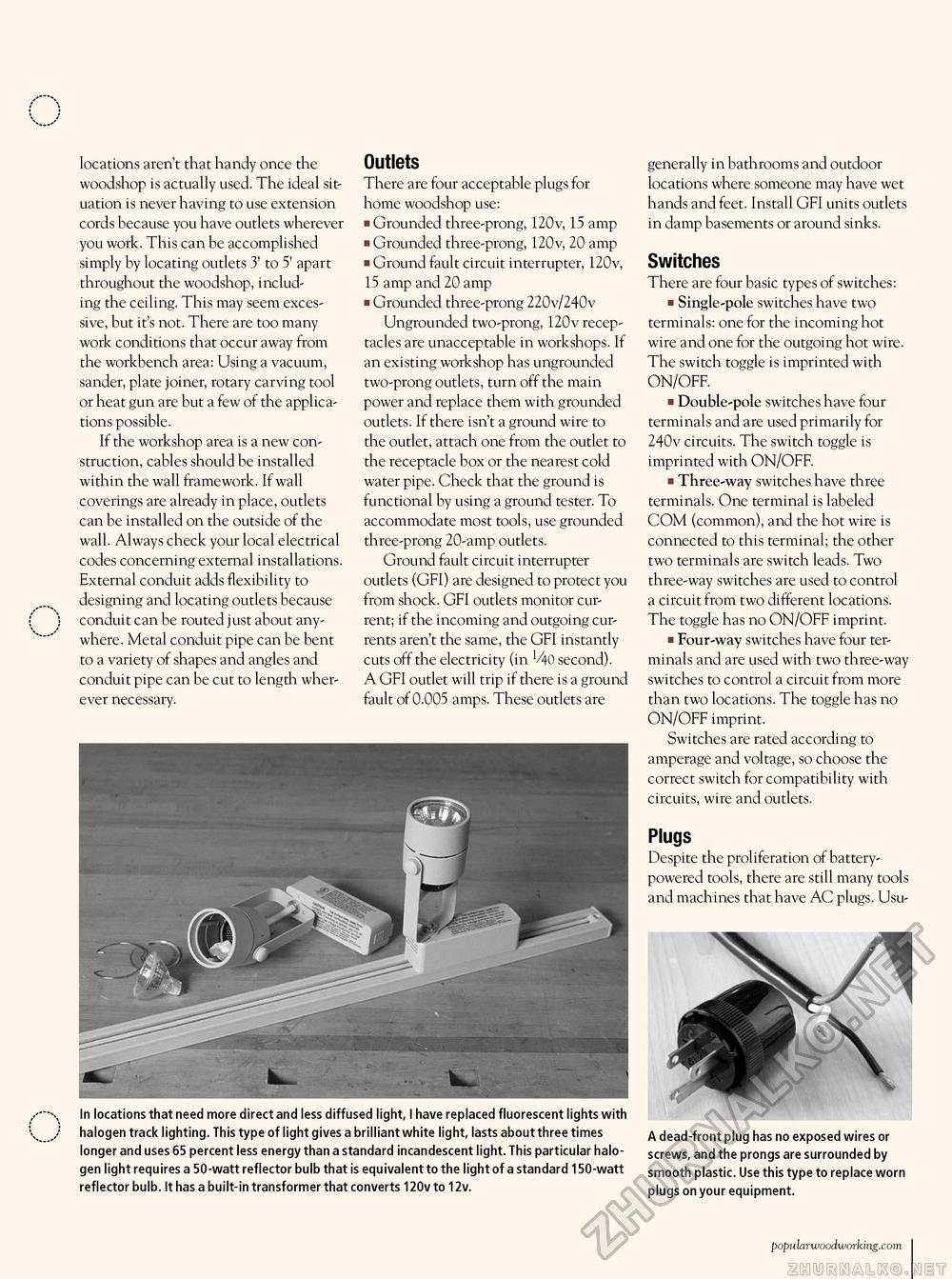

locations aren't that handy once the woodshop is actually used. The ideal situation is never having to use extension cords because you have outlets wherever you work. This can be accomplished simply by locating outlets 3' to 5' apart throughout the woodshop, including the ceiling. This may seem excessive, but it's not. There are too many work conditions that occur away from the workbench area: Using a vacuum, sander, plate joiner, rotary carving tool or heat gun are but a few of the applications possible. If the workshop area is a new construction, cables should be installed within the wall framework. If wall coverings are already in place, outlets can be installed on the outside of the wall. Always check your local electrical codes concerning external installations. External conduit adds flexibility to designing and locating outlets because conduit can be routed just about anywhere. Metal conduit pipe can be bent to a variety of shapes and angles and conduit pipe can be cut to length wherever necessary. Outlets There are four acceptable plugs for home woodshop use: ■ Grounded three-prong, 120v, 15 amp ■ Grounded three-prong, 120v, 20 amp ■ Ground fault circuit interrupter, 120v, 15 amp and 20 amp ■ Grounded three-prong 220v/240v Ungrounded two-prong, 120v receptacles are unacceptable in workshops. If an existing workshop has ungrounded two-prong outlets, turn off the main power and replace them with grounded outlets. If there isn't a ground wire to the outlet, attach one from the outlet to the receptacle box or the nearest cold water pipe. Check that the ground is functional by using a ground tester. To accommodate most tools, use grounded three-prong 20-amp outlets. Ground fault circuit interrupter outlets (GFI) are designed to protect you from shock. GFI outlets monitor current; if the incoming and outgoing currents aren't the same, the GFI instantly cuts off the electricity (in second). A GFI outlet will trip if there is a ground fault of 0.005 amps. These outlets are generally in bathrooms and outdoor locations where someone may have wet hands and feet. Install GFI units outlets in damp basements or around sinks. Switches There are four basic types of switches: ■ Single-pole switches have two terminals: one for the incoming hot wire and one for the outgoing hot wire. The switch toggle is imprinted with ON/OFF. ■ Double-pole switches have four terminals and are used primarily for 240v circuits. The switch toggle is imprinted with ON/OFF. ■ Three-way switches have three terminals. One terminal is labeled COM (common), and the hot wire is connected to this terminal; the other two terminals are switch leads. Two three-way switches are used to control a circuit from two different locations. The toggle has no ON/OFF imprint. ■ Four-way switches have four terminals and are used with two three-way switches to control a circuit from more than two locations. The toggle has no ON/OFF imprint. Switches are rated according to amperage and voltage, so choose the correct switch for compatibility with circuits, wire and outlets. Plugs Despite the proliferation of battery-powered tools, there are still many tools and machines that have AC plugs. Usu- A dead-front plug has no exposed wires or screws, and the prongs are surrounded by smooth plastic. Use this type to replace worn plugs on your equipment. In locations that need more direct and less diffused light, I have replaced fluorescent lights with halogen track lighting. This type of light gives a brilliant white light, lasts about three times longer and uses 65 percent less energy than a standard incandescent light. This particular halogen light requires a 50-watt reflector bulb that is equivalent to the light of a standard 150-watt reflector bulb. It has a built-in transformer that converts 120v to 12v. popularwoodworking.com i 33 |