Popular Woodworking 2006-11 № 158, страница 36

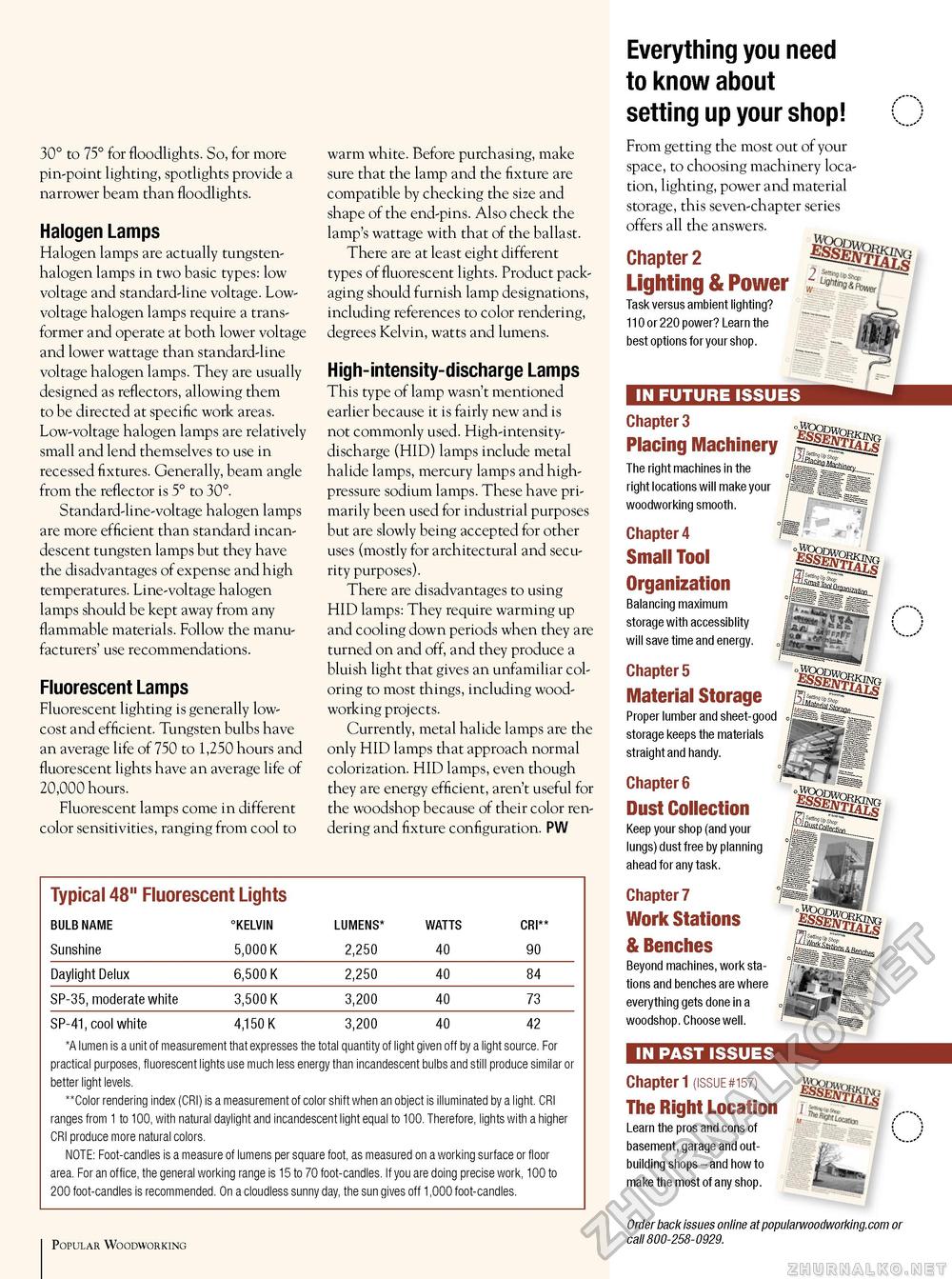

30° to 75° for floodlights. So, for more pin-point lighting, spotlights provide a narrower beam than floodlights. Halogen Lamps Halogen lamps are actually tungsten-halogen lamps in two basic types: low voltage and standard-line voltage. Low-voltage halogen lamps require a transformer and operate at both lower voltage and lower wattage than standard-line voltage halogen lamps. They are usually designed as reflectors, allowing them to be directed at specific work areas. Low-voltage halogen lamps are relatively small and lend themselves to use in recessed fixtures. Generally, beam angle from the reflector is 5° to 30°. Standard-line-voltage halogen lamps are more efficient than standard incandescent tungsten lamps but they have the disadvantages of expense and high temperatures. Line-voltage halogen lamps should be kept away from any flammable materials. Follow the manufacturers' use recommendations. Fluorescent Lamps Fluorescent lighting is generally low-cost and efficient. Tungsten bulbs have an average life of 750 to 1,250 hours and fluorescent lights have an average life of 20,000 hours. Fluorescent lamps come in different color sensitivities, ranging from cool to warm white. Before purchasing, make sure that the lamp and the fixture are compatible by checking the size and shape of the end-pins. Also check the lamp's wattage with that of the ballast. There are at least eight different types of fluorescent lights. Product packaging should furnish lamp designations, including references to color rendering, degrees Kelvin, watts and lumens. High-intensity-discharge Lamps This type of lamp wasn't mentioned earlier because it is fairly new and is not commonly used. High-intensity-discharge (HID) lamps include metal halide lamps, mercury lamps and high-pressure sodium lamps. These have primarily been used for industrial purposes but are slowly being accepted for other uses (mostly for architectural and security purposes). There are disadvantages to using HID lamps: They require warming up and cooling down periods when they are turned on and off, and they produce a bluish light that gives an unfamiliar coloring to most things, including woodworking projects. Currently, metal halide lamps are the only HID lamps that approach normal colorization. HID lamps, even though they are energy efficient, aren't useful for the woodshop because of their color rendering and fixture configuration. PW Typical 48" Fluorescent Lights

*A lumen is a unit of measurement that expresses the total quantity of light given off by a light source. For practical purposes, fluorescent lights use much less energy than incandescent bulbs and still produce similar or better light levels. "Color rendering index (CRI) is a measurement of color shift when an object is illuminated by a light. CRI ranges from 1 to 100, with natural daylight and incandescent light equal to 100. Therefore, lights with a higher CRI produce more natural colors. NOTE: Foot-candles is a measure of lumens per square foot, as measured on a working surface or floor area. For an office, the general working range is 15 to 70 foot-candles. If you are doing precise work, 100 to 200 foot-candles is recommended. On a cloudless sunny day, the sun gives off 1,000 foot-candles. Everything you need to know about setting up your shop! From getting the most out of your space, to choosing machinery location, lighting, power and material storage, this seven-chapter series offers all the answers. Chapter 2 Lighting & Power Task versus ambient lighting? 110 or 220 power? Learn the best options for your shop. IN FUTURE ISSUES Chapter 3 Placing Machinery The right machines in the right locations will make your woodworking smooth. Chapter 4 Small Tool Organization Balancing maximum storage with accessiblity will save time and energy. , Chapter 5 Material Storage Proper lumber and sheet-good storage keeps the materials straight and handy. Chapter 6 Dust Collection Keep your shop (and your lungs) dust free by planning ahead for any task. Chapter 7 ' Work Stations & Benches Beyond machines, work stations and benches are where everything gets done in a woodshop. Choose well. ^mag Popular Woodworking Order back issues online atpopularwoodworking.com or call 800-258-0929. |