Popular Woodworking 2006-11 № 158, страница 65

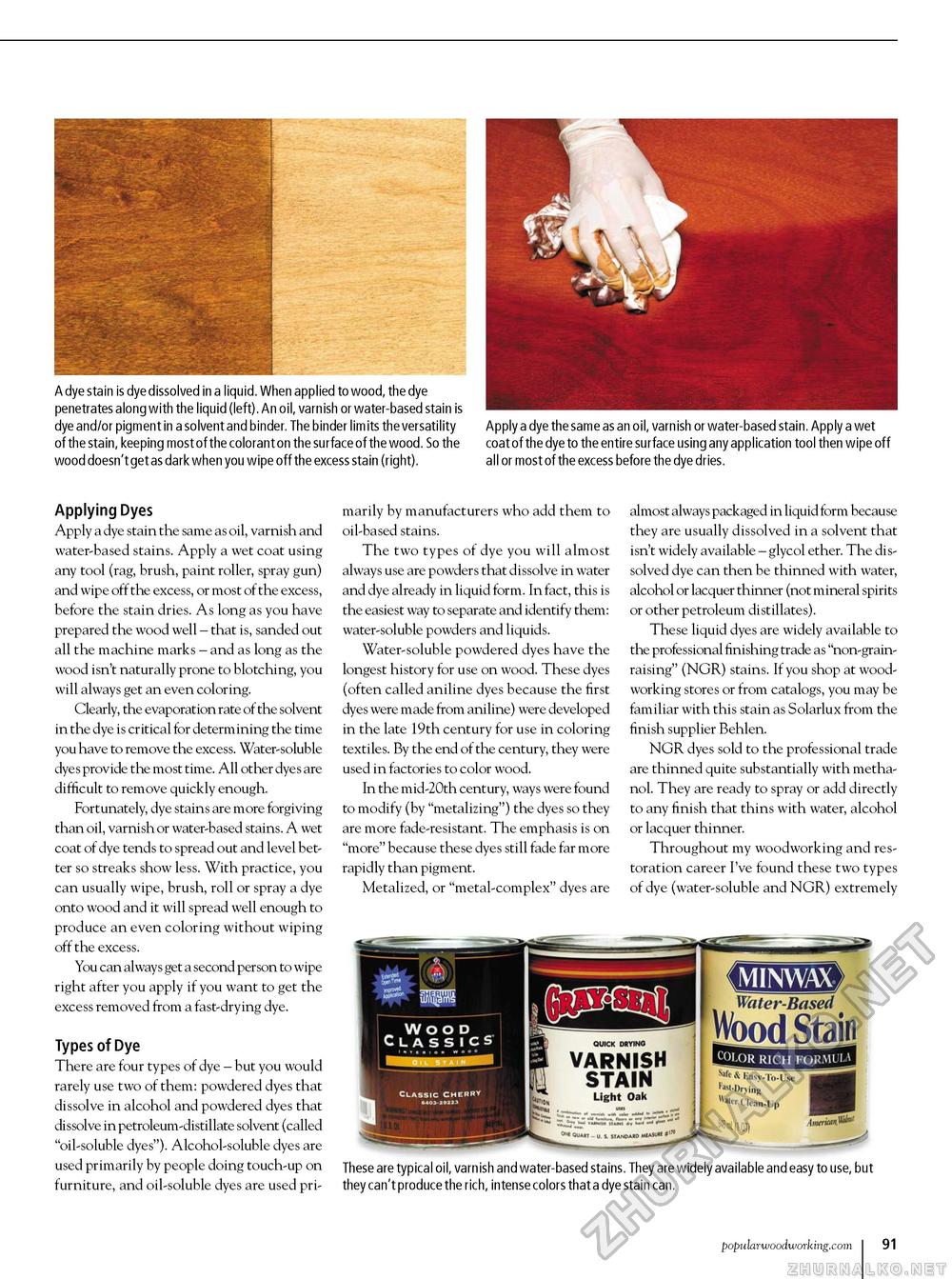

A dye stain is dye dissolved in a liquid. When applied to wood, the dye penetrates along with the liquid (left). An oil, varnish or water-based stain is dye and/or pigment in a solvent and binder. The binder lim its the versatility of the stain, keeping most of the colorant on the surface of the wood. So the wood doesn't get as dark when you wipe off the excess stain (right). Apply a dye the same as an oil, varnish or water-based stain. Apply a wet coat of the dye to the entire surface using any application tool then wipe off all or most of the excess before the dye dries. Applying Dyes Apply a dye stain the same as oil, varnish and water-based stains. Apply a wet coat using any tool (rag, brush, paint roller, spray gun) and wipe off the excess, or most of the excess, before the stain dries. As long as you have prepared the wood well - that is, sanded out all the machine marks - and as long as the wood isn't naturally prone to blotching, you will always get an even coloring. Clearly, the evaporation rate of the solvent in the dye is critical for determining the time you have to remove the excess. Water-soluble dyes provide the most time. All other dyes are difficult to remove quickly enough. Fortunately, dye stains are more forgiving than oil, varnish or water-based stains. A wet coat of dye tends to spread out and level better so streaks show less. With practice, you can usually wipe, brush, roll or spray a dye onto wood and it will spread well enough to produce an even coloring without wiping off the excess. You can always get a second person to wipe right after you apply if you want to get the excess removed from a fast-drying dye. Types of Dye There are four types of dye - but you would rarely use two of them: powdered dyes that dissolve in alcohol and powdered dyes that dissolve in petroleum-distillate solvent (called "oil-soluble dyes"). Alcohol-soluble dyes are used primarily by people doing touch-up on furniture, and oil-soluble dyes are used pri marily by manufacturers who add them to oil-based stains. The two types of dye you will almost always use are powders that dissolve in water and dye already in liquid form. In fact, this is the easiest way to separate and identify them: water-soluble powders and liquids. Water-soluble powdered dyes have the longest history for use on wood. These dyes (often called aniline dyes because the first dyes were made from aniline) were developed in the late 19th century for use in coloring textiles. By the end of the century, they were used in factories to color wood. In the mid-20th century, ways were found to modify (by "metalizing") the dyes so they are more fade-resistant. The emphasis is on "more" because these dyes still fade far more rapidly than pigment. Metalized, or "metal-complex" dyes are almost always packaged in liquid form because they are usually dissolved in a solvent that isn't widely available - glycol ether. The dissolved dye can then be thinned with water, alcohol or lacquer thinner (not mineral spirits or other petroleum distillates). These liquid dyes are widely available to the professional finishing trade as ""non-grain-raising" (NGR) stains. If you shop at woodworking stores or from catalogs, you may be familiar with this stain as Solarlux from the finish supplier Behlen. NGR dyes sold to the professional trade are thinned quite substantially with metha-nol. They are ready to spray or add directly to any finish that thins with water, alcohol or lacquer thinner. Throughout my woodworking and restoration career I've found these two types of dye (water-soluble and NGR) extremely These are typical oil, varnish and water-based stains. They are widely available and easy to use, but they can't produce the rich, intense colors that a dye stain can. popularwoodworking.com i 91 |