Popular Woodworking 2006-11 № 158, страница 66

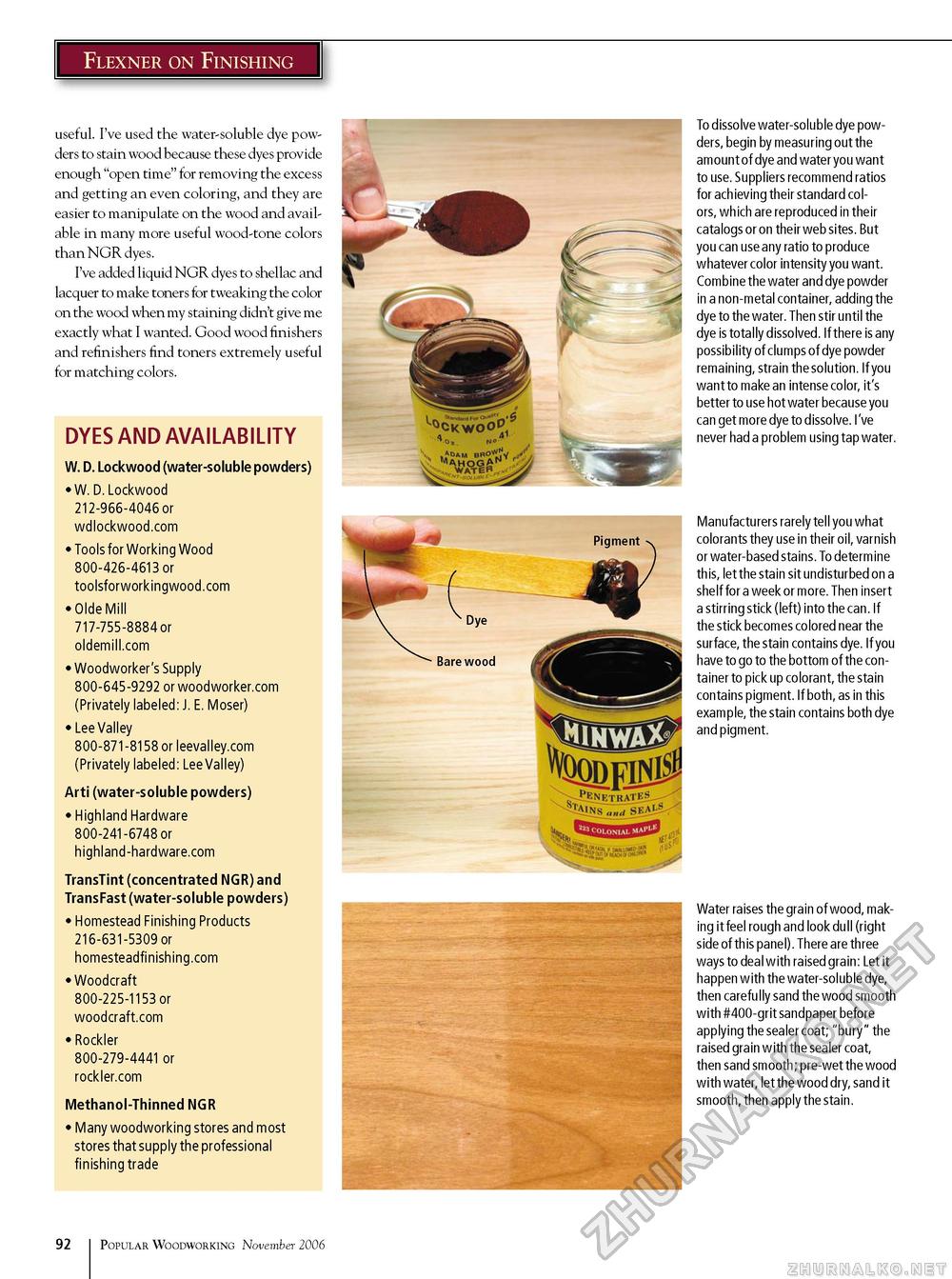

Flexner on Finishing r useful. I've used the water-soluble dye powders to stain wood because these dyes provide enough "open time" for removing the excess and getting an even coloring, and they are easier to manipulate on the wood and available in many more useful wood-tone colors than NGR dyes. I've added liquid NGR dyes to shellac and lacquer to make toners for tweaking the color on the wood when my staining didn't give me exactly what I wanted. Good wood finishers and refinishers find toners extremely useful for matching colors. DYES AND AVAILABILITY W. D. Lockwood (water-soluble powders) • W. D. Lockwood 212-966-4046 or wdlockwood.com • Tools for Working Wood 800-426-4613 or toolsforworkingwood.com • Olde Mill 717-755-8884 or oldemill.com • Woodworker's Supply 800-645-9292 or woodworker.com (Privately labeled: J. E. Moser) • Lee Valley 800-871-8158 or leevalley.com (Privately labeled: Lee Valley) Arti (water-soluble powders) • Highland Hardware 800-241-6748 or highland-hardware.com TransTint (concentrated NGR) and TransFast (water-soluble powders) • Homestead Finishing Products 216-631-5309 or homesteadfinishing.com • Woodcraft 800-225-1153 or woodcraft.com • Rockler 800-279-4441 or rockler.com Methanol-Thinned NGR • Many woodworking stores and most stores that supply the professional finishing trade To dissolve water-soluble dye powders, begin by measuring out the amount of dye and water you want to use. Suppliers recommend ratios for achieving their standard colors, which are reproduced in their catalogs or on their web sites. But you can use any ratio to produce whatever color intensity you want. Combine the water and dye powder in a non-metal container, adding the dye to the water. Then stir until the dye is totally dissolved. If there is any possibility of clumps of dye powder remaining, strain the solution. If you want to make an intense color, it's better to use hot water because you can get more dye to dissolve. I've never had a problem using tap water. Manufacturers rarely tell you what colorants they use in their oil, varnish or water-based stains. To determine this, let the stain sit undisturbed on a shelf for a week or more. Then insert a stirring stick (left) into the can. If the stick becomes colored near the surface, the stain contains dye. If you have to go to the bottom of the container to pick up colorant, the stain contains pigment. If both, as in this example, the stain contains both dye and pigment. Water raises the grain of wood, making it feel rough and look dull (right side of this panel). There are three ways to deal with raised grain: Let it happen with the water-soluble dye, then carefully sand the wood smooth with #400-grit sandpaper before applying the sealer coat; "bury" the raised grain with the sealer coat, then sand smooth; pre-wet the wood with water, let the wood dry, sand it smooth, then apply the stain. 92 Popular Woodworking November 2006 |