Popular Woodworking 2006-12 № 159, страница 38

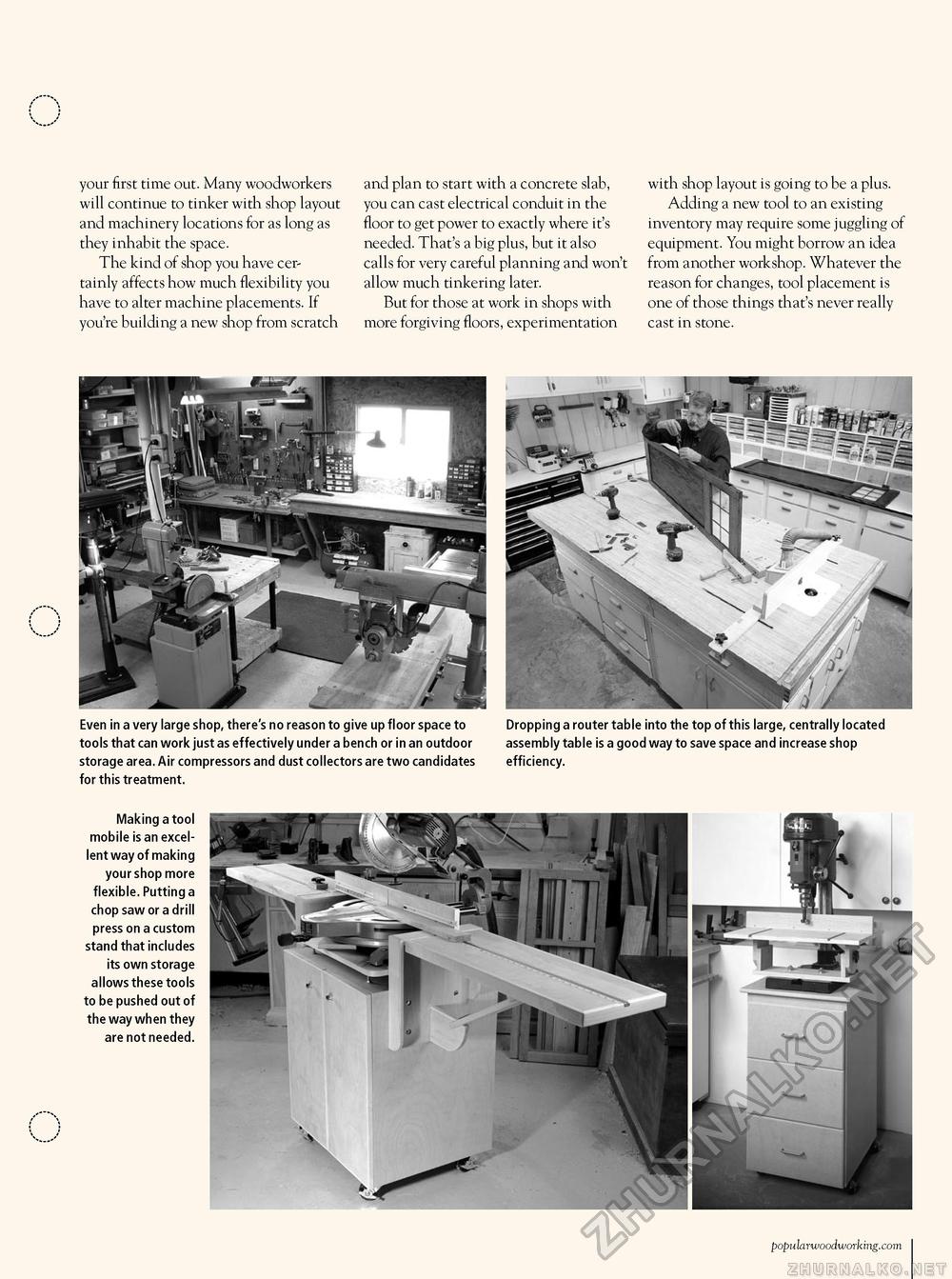

your first time out. Many woodworkers will continue to tinker with shop layout and machinery locations for as long as they inhabit the space. The kind of shop you have certainly affects how much flexibility you have to alter machine placements. If you're building a new shop from scratch and plan to start with a concrete slab, you can cast electrical conduit in the floor to get power to exactly where it's needed. That's a big plus, but it also calls for very careful planning and won't allow much tinkering later. But for those at work in shops with more forgiving floors, experimentation with shop layout is going to be a plus. Adding a new tool to an existing inventory may require some juggling of equipment. You might borrow an idea from another workshop. Whatever the reason for changes, tool placement is one of those things that's never really cast in stone. Even in a very large shop, there's no reason to give up floor space to tools that can work just as effectively under a bench or in an outdoor storage area. Air compressors and dust collectors are two candidates for this treatment. Dropping a router table into the top of this large, centrally located assembly table is a good way to save space and increase shop efficiency. Making a tool mobile is an excellent way of making your shop more flexible. Putting a chop saw or a drill press on a custom stand that includes its own storage allows these tools to be pushed out of the way when they are not needed. popularwoodworking.com i 38 |