Popular Woodworking 2006-12 № 159, страница 35

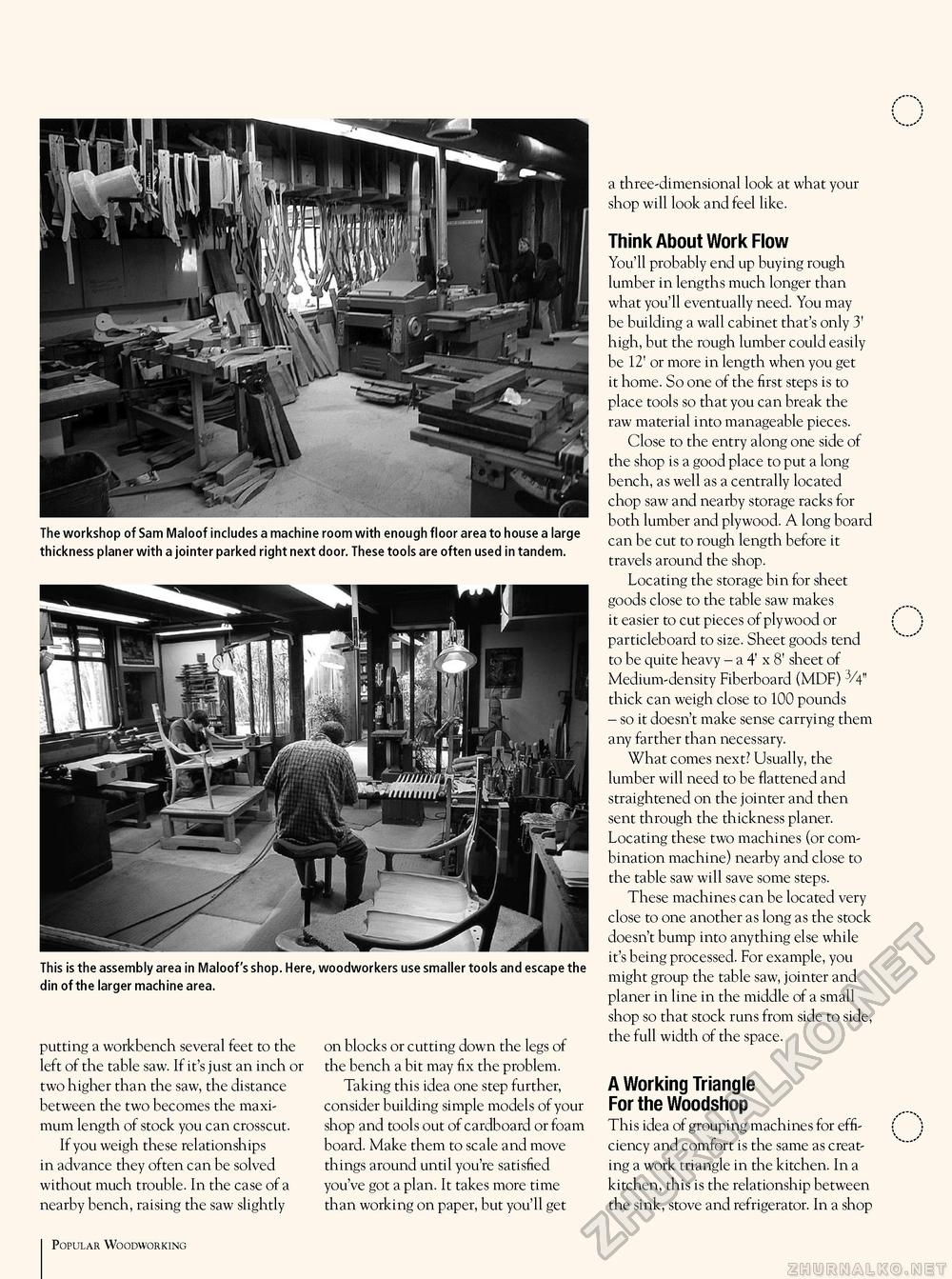

The workshop of Sam Maloof includes a machine room with enough floor area to house a large thickness planer with a jointer parked right next door. These tools are often used in tandem. This is the assembly area in Maloof's shop. Here, woodworkers use smaller tools and escape the din of the larger machine area. putting a workbench several feet to the left of the table saw. If it's just an inch or two higher than the saw, the distance between the two becomes the maximum length of stock you can crosscut. If you weigh these relationships in advance they often can be solved without much trouble. In the case of a nearby bench, raising the saw slightly on blocks or cutting down the legs of the bench a bit may fix the problem. Taking this idea one step further, consider building simple models of your shop and tools out of cardboard or foam board. Make them to scale and move things around until you're satisfied you've got a plan. It takes more time than working on paper, but you'll get a three-dimensional look at what your shop will look and feel like. Think About Work Flow You'll probably end up buying rough lumber in lengths much longer than what you'll eventually need. You may be building a wall cabinet that's only 3' high, but the rough lumber could easily be 12' or more in length when you get it home. So one of the first steps is to place tools so that you can break the raw material into manageable pieces. Close to the entry along one side of the shop is a good place to put a long bench, as well as a centrally located chop saw and nearby storage racks for both lumber and plywood. A long board can be cut to rough length before it travels around the shop. Locating the storage bin for sheet goods close to the table saw makes it easier to cut pieces of plywood or particleboard to size. Sheet goods tend to be quite heavy - a 4' x 8' sheet of Medium-density Fiberboard (MDF) 3/4" thick can weigh close to 100 pounds - so it doesn't make sense carrying them any farther than necessary. What comes next? Usually, the lumber will need to be flattened and straightened on the jointer and then sent through the thickness planer. Locating these two machines (or combination machine) nearby and close to the table saw will save some steps. These machines can be located very close to one another as long as the stock doesn't bump into anything else while it's being processed. For example, you might group the table saw, jointer and planer in line in the middle of a small shop so that stock runs from side to side, the full width of the space. A Working Triangle For the Woodshop This idea of grouping machines for efficiency and comfort is the same as creating a work triangle in the kitchen. In a kitchen, this is the relationship between the sink, stove and refrigerator. In a shop Popular Woodworking |