Popular Woodworking 2006-12 № 159, страница 33

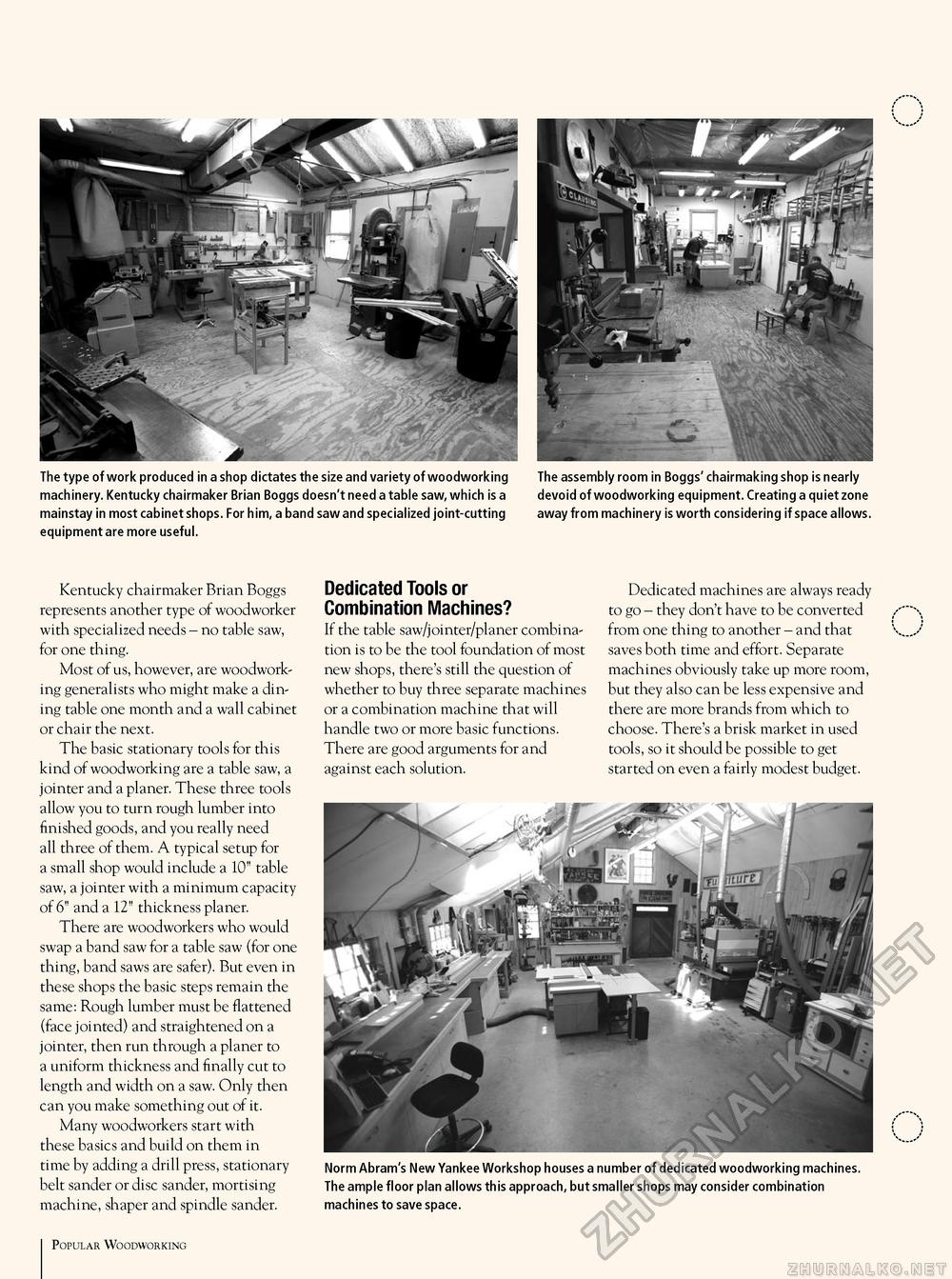

The type of work produced in a shop dictates the size and variety of woodworking machinery. Kentucky chairmaker Brian Boggs doesn't need a table saw, which is a mainstay in most cabinet shops. For him, a band saw and specialized joint-cutting equipment are more useful. The assembly room in Boggs' chairmaking shop is nearly devoid of woodworking equipment. Creating a quiet zone away from machinery is worth considering if space allows. Kentucky chairmaker Brian Boggs represents another type of woodworker with specialized needs - no table saw, for one thing. Most of us, however, are woodworking generalists who might make a dining table one month and a wall cabinet or chair the next. The basic stationary tools for this kind of woodworking are a table saw, a jointer and a planer. These three tools allow you to turn rough lumber into finished goods, and you really need all three of them. A typical setup for a small shop would include a 10" table saw, a jointer with a minimum capacity of 6" and a 12" thickness planer. There are woodworkers who would swap a band saw for a table saw (for one thing, band saws are safer). But even in these shops the basic steps remain the same: Rough lumber must be flattened (face jointed) and straightened on a jointer, then run through a planer to a uniform thickness and finally cut to length and width on a saw. Only then can you make something out of it. Many woodworkers start with these basics and build on them in time by adding a drill press, stationary belt sander or disc sander, mortising machine, shaper and spindle sander. Dedicated Tools or Combination Machines? If the table saw/jointer/planer combination is to be the tool foundation of most new shops, there's still the question of whether to buy three separate machines or a combination machine that will handle two or more basic functions. There are good arguments for and against each solution. Dedicated machines are always ready to go - they don't have to be converted from one thing to another - and that saves both time and effort. Separate machines obviously take up more room, but they also can be less expensive and there are more brands from which to choose. There's a brisk market in used tools, so it should be possible to get started on even a fairly modest budget. Norm Abram's New Yankee Workshop houses a number of dedicated woodworking machines. The ample floor plan allows this approach, but smaller shops may consider combination machines to save space. Popular Woodworking |