Popular Woodworking 2007-02 № 160, страница 53

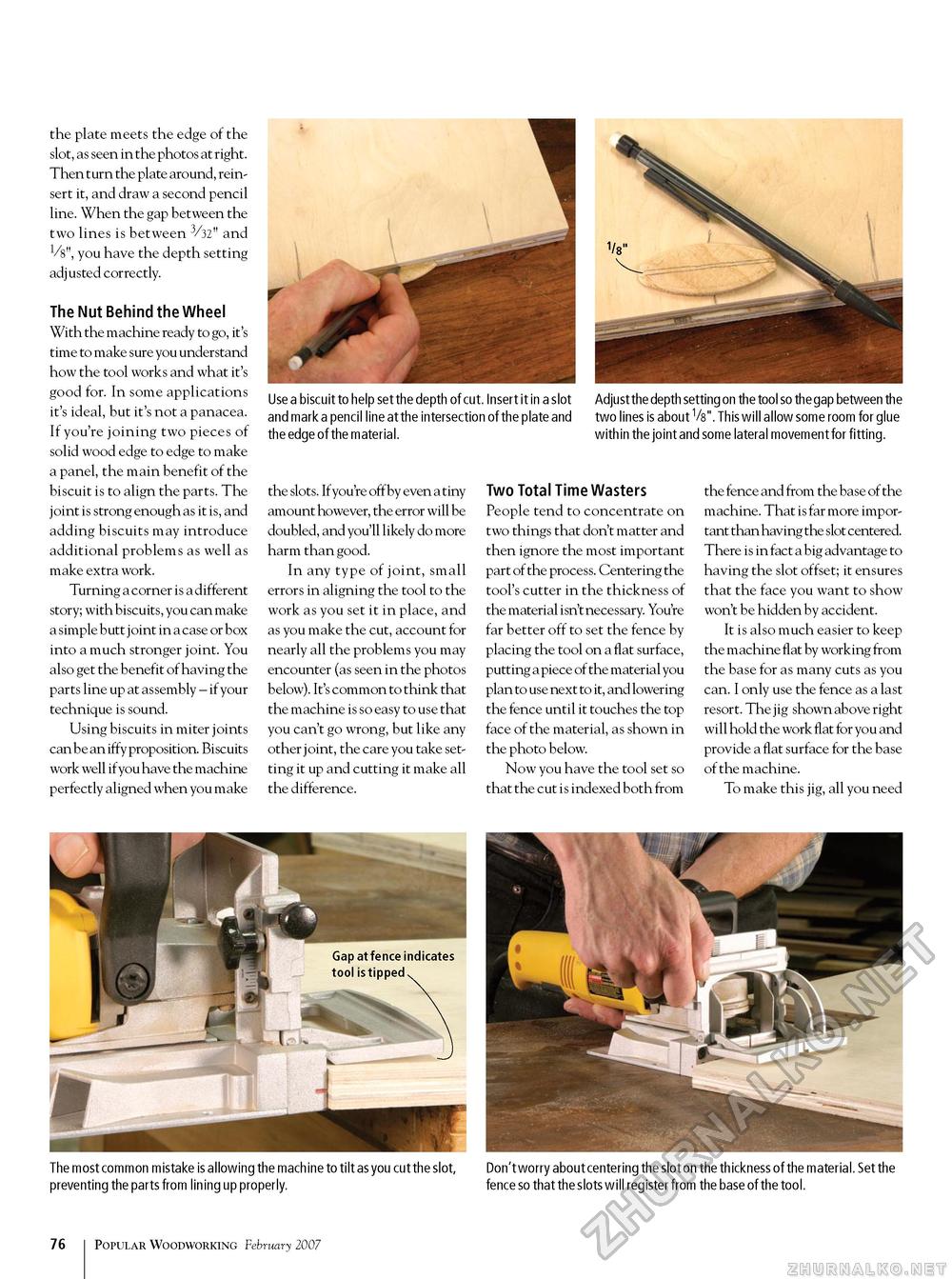

Use a biscuit to help set the depth of cut. Insert it in a slot and mark a pencil line at the intersection of the plate and the edge of the material. Adjust the depth setting on the tool so the gap between the two lines is about Vs". This will allow some room for glue within the joint and some lateral movement for fitting. the plate meets the edge of the slot, as seen in the photos at right. Then turn the plate around, reinsert it, and draw a second pencil line. When the gap between the two lines is between 3/32" and Vs", you have the depth setting adjusted correctly. The Nut Behind the Wheel With the machine ready to go, it's time to make sure you understand how the tool works and what it's good for. In some applications it's ideal, but it's not a panacea. If you're joining two pieces of solid wood edge to edge to make a panel, the main benefit of the biscuit is to align the parts. The joint is strong enough as it is, and adding biscuits may introduce additional problems as well as make extra work. Turning a corner is a different story; with biscuits, you can make a simple butt joint in a case or box into a much stronger joint. You also get the benefit of having the parts line up at assembly - if your technique is sound. Using biscuits in miter joints can be an iffy proposition. Biscuits work well if you have the machine perfectly aligned when you make the slots. If you're off by even a tiny amount however, the error will be doubled, and you'll likely do more harm than good. In any type of joint, small errors in aligning the tool to the work as you set it in place, and as you make the cut, account for nearly all the problems you may encounter (as seen in the photos below). It's common to think that the machine is so easy to use that you can't go wrong, but like any other joint, the care you take setting it up and cutting it make all the difference. Two Total Time Wasters People tend to concentrate on two things that don't matter and then ignore the most important part of the process. Centering the tool's cutter in the thickness of the material isn't necessary. You're far better off to set the fence by placing the tool on a flat surface, putting a piece of the material you plan to use next to it, and lowering the fence until it touches the top face of the material, as shown in the photo below. Now you have the tool set so that the cut is indexed both from the fence and from the base of the machine. That is far more important than having the slot centered. There is in fact a big advantage to having the slot offset; it ensures that the face you want to show won't be hidden by accident. It is also much easier to keep the machine flat by working from the base for as many cuts as you can. I only use the fence as a last resort. The jig shown above right will hold the work flat for you and provide a flat surface for the base of the machine. To make this jig, all you need The most common mistake is allowing the machine to tilt as you cut the slot, Don't worry about centering the slot on the thickness of the material. Set the preventing the parts from lining up properly. fence so that the slots will register from the base of the tool. 10 Popular Woodworking February 2007 |