Popular Woodworking 2007-02 № 160, страница 56

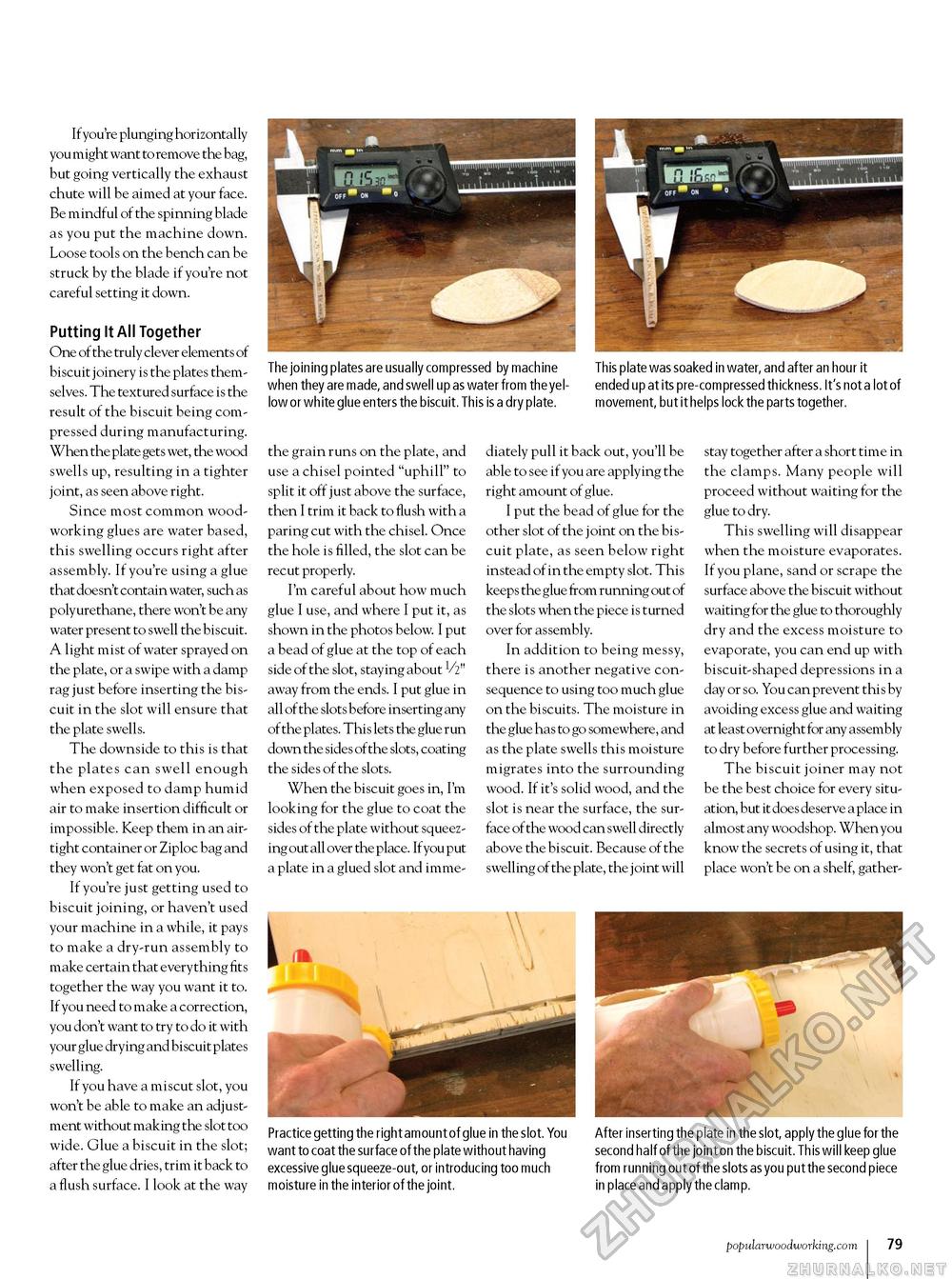

The joining plates are usually compressed by machine This plate was soaked in water, and after an hour it when they are made, and swell up as water from the yel- ended up at its pre-compressed thickness. It's not a lot of low or white glue enters the biscuit. This is a dry plate. movement, but it helps lock the parts together. If you're plunging horizontally you might want to remove the bag, but going vertically the exhaust chute will be aimed at your face. Be mindful of the spinning blade as you put the machine down. Loose tools on the bench can be struck by the blade if you're not careful setting it down. Putting it a 11 Together One of the truly clever elements of biscuit joinery is the plates themselves. The textured surface is the result of the biscuit being compressed during manufacturing. When the plate gets wet, the wood swells up, resulting in a tighter joint, as seen above right. Since most common woodworking glues are water based, this swelling occurs right after assembly. If you're using a glue that doesn't contain water, such as polyurethane, there won't be any water present to swell the biscuit. A light mist of water sprayed on the plate, or a swipe with a damp rag just before inserting the biscuit in the slot will ensure that the plate swells. The downside to this is that the plates can swell enough when exposed to damp humid air to make insertion difficult or impossible. Keep them in an airtight container or Ziploc bag and they won't get fat on you. If you're just getting used to biscuit joining, or haven't used your machine in a while, it pays to make a dry-run assembly to make certain that everything fits together the way you want it to. If you need to make a correction, you don't want to try to do it with your glue drying and biscuit plates swelling. If you have a miscut slot, you won't be able to make an adjustment without making the slot too wide. Glue a biscuit in the slot; after the glue dries, trim it back to a flush surface. I look at the way the grain runs on the plate, and use a chisel pointed "uphill" to split it off just above the surface, then I trim it back to flush with a paring cut with the chisel. Once the hole is filled, the slot can be recut properly. I'm careful about how much glue I use, and where I put it, as shown in the photos below. I put a bead of glue at the top of each side of the slot, staying about V2" away from the ends. I put glue in all of the slots before inserting any of the plates. This lets the glue run down the sides of the slots, coating the sides of the slots. When the biscuit goes in, I'm looking for the glue to coat the sides of the plate without squeezing out all over the place. If you put a plate in a glued slot and imme- diately pull it back out, you'll be able to see if you are applying the right amount of glue. I put the bead of glue for the other slot of the joint on the biscuit plate, as seen below right instead of in the empty slot. This keeps the glue from running out of the slots when the piece is turned over for assembly. In addition to being messy, there is another negative consequence to using too much glue on the biscuits. The moisture in the glue has to go somewhere, and as the plate swells this moisture migrates into the surrounding wood. If it's solid wood, and the slot is near the surface, the surface of the wood can swell directly above the biscuit. Because of the swelling of the plate, the joint will stay together after a short time in the clamps. Many people will proceed without waiting for the glue to dry. This swelling will disappear when the moisture evaporates. If you plane, sand or scrape the surface above the biscuit without waiting for the glue to thoroughly dry and the excess moisture to evaporate, you can end up with biscuit-shaped depressions in a day or so. You can prevent this by avoiding excess glue and waiting at least overnight for any assembly to dry before further processing. The biscuit joiner may not be the best choice for every situation, but it does deserve a place in almost any woodshop. When you know the secrets of using it, that place won't be on a shelf, gather- Practice getting the right amount of glue in the slot. You want to coat the surface of the plate without having excessive glue squeeze-out, or introducing too much moisture in the interior of the joint. After inserting the plate in the slot, apply the glue for the second half of the joint on the biscuit. This will keep glue from running out of the slots as you put the second piece in place and apply the clamp. popularwoodworking.com 31 |