Popular Woodworking 2007-04 № 161, страница 12

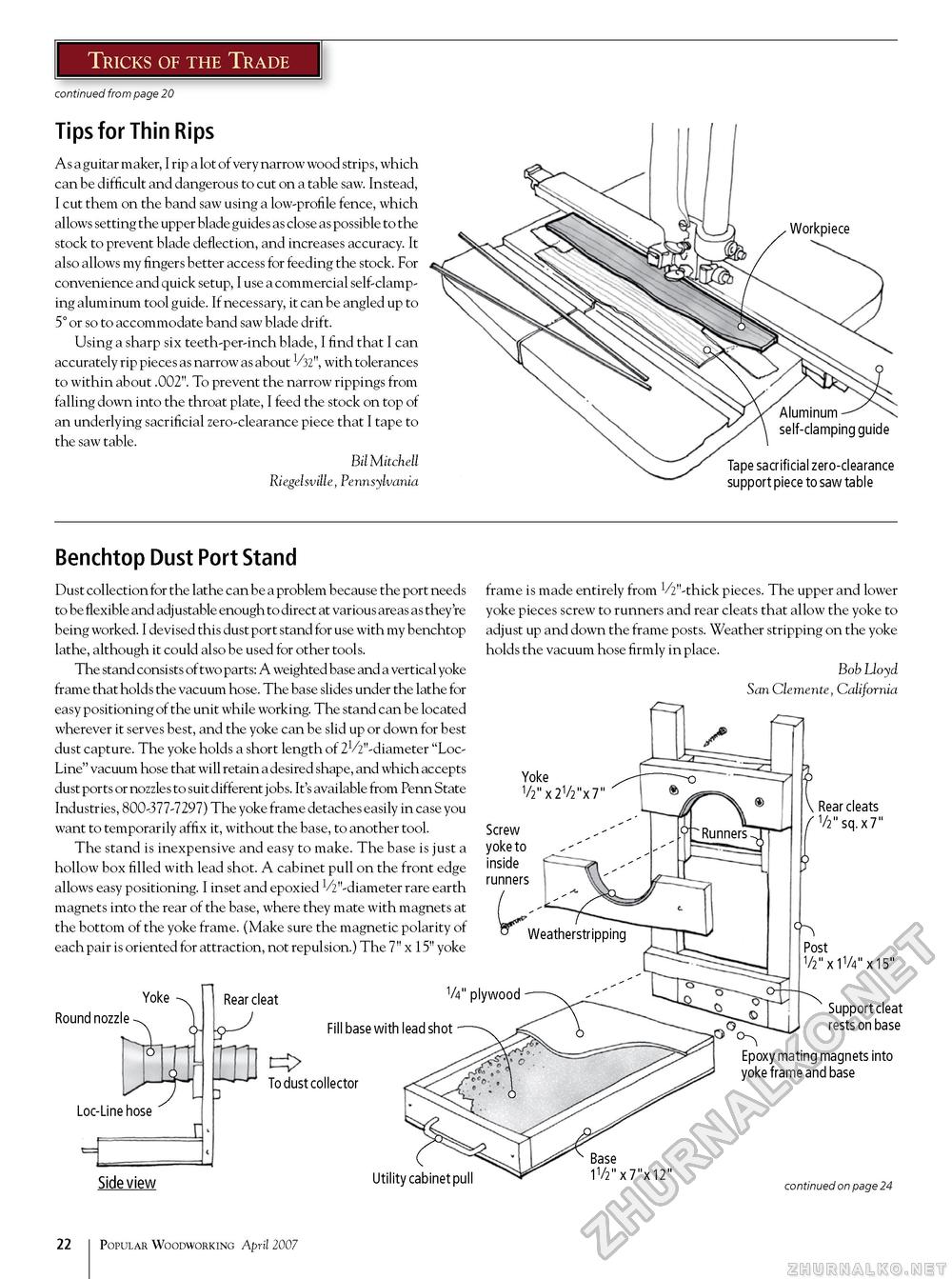

Tricks of the Trade continued from page 20 Tips for Thin Rips As a guitar maker, I rip a lot of very narrow wood strips, which can be difficult and dangerous to cut on a table saw. Instead, I cut them on the band saw using a low-profile fence, which allows setting the upper blade guides as close as possible to the stock to prevent blade deflection, and increases accuracy. It also allows my fingers better access for feeding the stock. For convenience and quick setup, I use a commercial self-clamping aluminum tool guide. If necessary, it can be angled up to 5° or so to accommodate band saw blade drift. Using a sharp six teeth-per-inch blade, I find that I can accurately rip pieces as narrow as about V32", with tolerances to within about .002". To prevent the narrow rippings from falling down into the throat plate, I feed the stock on top of an underlying sacrificial zero-clearance piece that I tape to the saw table. Bil Mitchell Riegelsville, Pennsylvania Aluminum self-clamping guide Tape sacrificial zero-clearance support piece to saw table Benchtop Dust Port Stand Dust collection for the lathe can be a problem because the port needs to be flexible and adjustable enough to direct at various areas as they're being worked. I devised this dust port stand for use with my benchtop lathe, although it could also be used for other tools. The stand consists of two parts: A weighted base and a vertical yoke frame that holds the vacuum hose. The base slides under the lathe for easy positioning of the unit while working. The stand can be located wherever it serves best, and the yoke can be slid up or down for best dust capture. The yoke holds a short length of 21/2"-diameter "Loc-Line" vacuum hose that will retain a desired shape, and which accepts dust ports or nozzles to suit different jobs. It's available from Penn State Industries, 800-377-7297) The yoke frame detaches easily in case you want to temporarily affix it, without the base, to another tool. The stand is inexpensive and easy to make. The base is just a hollow box filled with lead shot. A cabinet pull on the front edge allows easy positioning. I inset and epoxied ^"-diameter rare earth magnets into the rear of the base, where they mate with magnets at the bottom of the yoke frame. (Make sure the magnetic polarity of each pair is oriented for attraction, not repulsion.) The 7" x 15" yoke frame is made entirely from V2"-thick pieces. The upper and lower yoke pieces screw to runners and rear cleats that allow the yoke to adjust up and down the frame posts. Weather stripping on the yoke holds the vacuum hose firmly in place. Bob Lloyd San Clemente, California 22 Popular Woodworking April 2007 |