Popular Woodworking 2007-04 № 161, страница 20

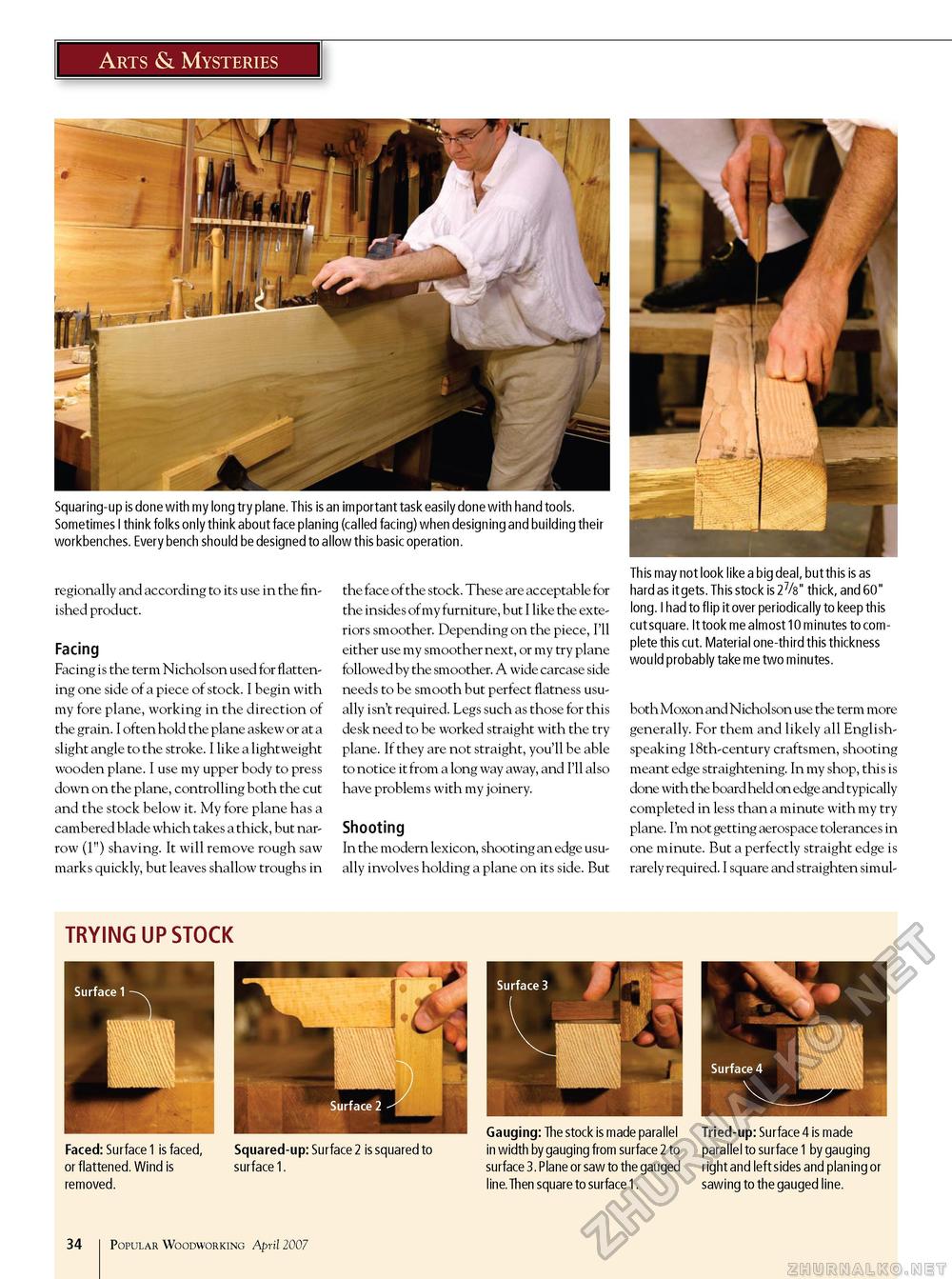

Arts & Mysteries Squaring-up is done with my long try plane. This is an important task easily done with hand tools. Sometimes I think folks only think about face planing (called facing) when designing and building their workbenches. Every bench should be designed to allow this basic operation. regionally and according to its use in the finished product. Facing Facing is the term Nicholson used for flattening one side of a piece of stock. I begin with my fore plane, working in the direction of the grain. I often hold the plane askew or at a slight angle to the stroke. I like a lightweight wooden plane. I use my upper body to press down on the plane, controlling both the cut and the stock below it. My fore plane has a cambered blade which takes a thick, but narrow (1"") shaving. It will remove rough saw marks quickly, but leaves shallow troughs in the face of the stock. These are acceptable for the insides of my furniture, but I like the exteriors smoother. Depending on the piece, I'll either use my smoother next, or my try plane followed by the smoother. A wide carcase side needs to be smooth but perfect flatness usually isn't required. Legs such as those for this desk need to be worked straight with the try plane. If they are not straight, you'll be able to notice it from a long way away, and I'll also have problems with my joinery. Shooting In the modern lexicon, shooting an edge usually involves holding a plane on its side. But This may not look like a big deal, but this is as hard as it gets. This stock is 27/s" thick, and 60" long. I had to flip it over periodically to keep this cut square. It took me almost 10 minutes to complete this cut. Material one-third this thickness would probably take me two minutes. both Moxon and Nicholson use the term more generally. For them and likely all English-speaking 18th-century craftsmen, shooting meant edge straightening. In my shop, this is done with the board held on edge and typically completed in less than a minute with my try plane. I'm not getting aerospace tolerances in one minute. But a perfectly straight edge is rarely required. I square and straighten simul- TRYING UP STOCK Faced: Surface 1 is faced, or flattened. Wind is removed. Squared-up: Surface 2 is squared to surface 1.

gauging: The stock is made parallel in width by gauging from surface 2 to surface 3. Plane or saw to the gauged line. Then square to surface 1.

Tried-up: Surface 4 is made parallel to surface 1 by gauging right and left sides and planing or sawing to the gauged line. 34 Popular Woodworking April 2007 |

|||||||||||||||||||||||||||