Popular Woodworking 2007-04 № 161, страница 33

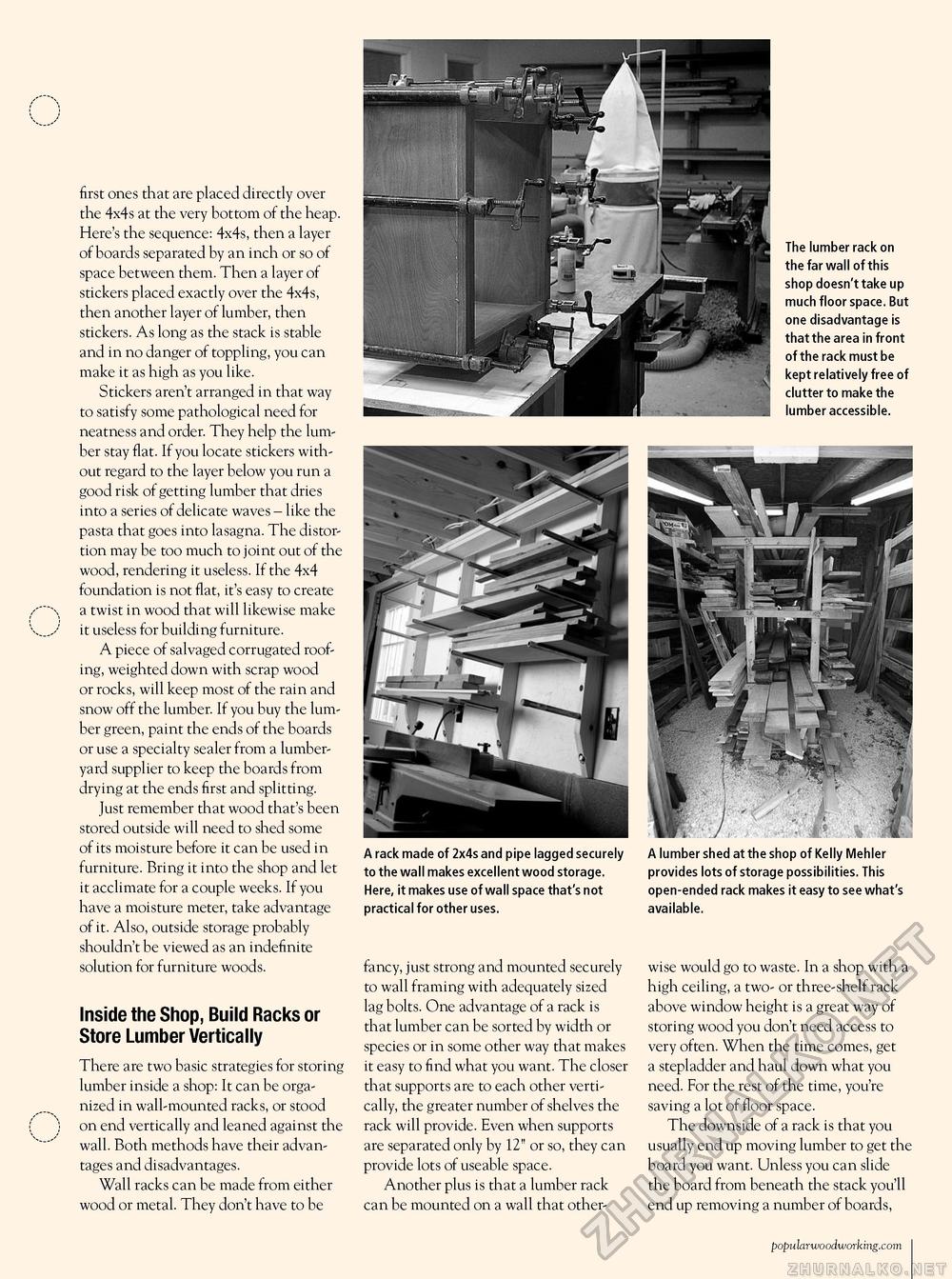

first ones that are placed directly over the 4x4s at the very bottom of the heap. Here's the sequence: 4x4s, then a layer of boards separated by an inch or so of space between them. Then a layer of stickers placed exactly over the 4x4s, then another layer of lumber, then stickers. As long as the stack is stable and in no danger of toppling, you can make it as high as you like. Stickers aren't arranged in that way to satisfy some pathological need for neatness and order. They help the lumber stay flat. If you locate stickers without regard to the layer below you run a good risk of getting lumber that dries into a series of delicate waves - like the pasta that goes into lasagna. The distortion may be too much to joint out of the wood, rendering it useless. If the 4x4 foundation is not flat, it's easy to create a twist in wood that will likewise make it useless for building furniture. A piece of salvaged corrugated roofing, weighted down with scrap wood or rocks, will keep most of the rain and snow off the lumber. If you buy the lumber green, paint the ends of the boards or use a specialty sealer from a lumberyard supplier to keep the boards from drying at the ends first and splitting. Just remember that wood that's been stored outside will need to shed some of its moisture before it can be used in furniture. Bring it into the shop and let it acclimate for a couple weeks. If you have a moisture meter, take advantage of it. Also, outside storage probably shouldn't be viewed as an indefinite solution for furniture woods. Inside the Shop, Build Racks or Store Lumber Vertically There are two basic strategies for storing lumber inside a shop: It can be organized in wall-mounted racks, or stood on end vertically and leaned against the wall. Both methods have their advantages and disadvantages. Wall racks can be made from either wood or metal. They don't have to be The lumber rack on the far wall of this shop doesn't take up much floor space. But one disadvantage is that the area in front of the rack must be kept relatively free of clutter to make the lumber accessible. A rack made of 2x4s and pipe lagged securely to the wall makes excellent wood storage. Here, it makes use of wall space that's not practical for other uses. fancy, just strong and mounted securely to wall framing with adequately sized lag bolts. One advantage of a rack is that lumber can be sorted by width or species or in some other way that makes it easy to find what you want. The closer that supports are to each other vertically, the greater number of shelves the rack will provide. Even when supports are separated only by 12" or so, they can provide lots of useable space. Another plus is that a lumber rack can be mounted on a wall that other- A lumber shed at the shop of Kelly Mehler provides lots of storage possibilities. This open-ended rack makes it easy to see what's available. wise would go to waste. In a shop with a high ceiling, a two- or three-shelf rack above window height is a great way of storing wood you don't need access to very often. When the time comes, get a stepladder and haul down what you need. For the rest of the time, you're saving a lot of floor space. The downside of a rack is that you usually end up moving lumber to get the board you want. Unless you can slide the board from beneath the stack you'll end up removing a number of boards, popularwoodworking.com I 33 |