Popular Woodworking 2007-04 № 161, страница 35

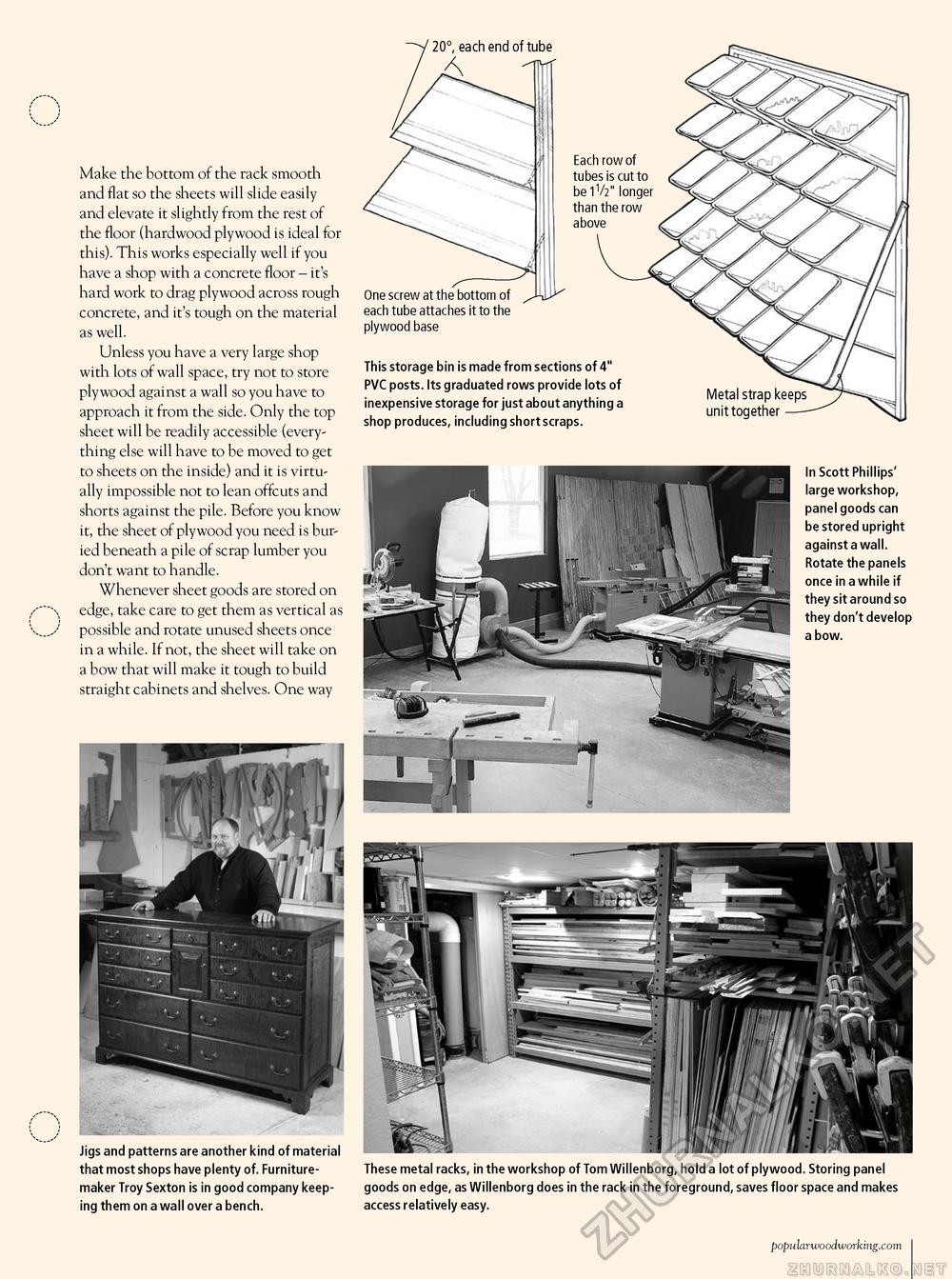

Make the bottom of the rack smooth and flat so the sheets will slide easily and elevate it slightly from the rest of the floor (hardwood plywood is ideal for this). This works especially well if you have a shop with a concrete floor - it's hard work to drag plywood across rough concrete, and it's tough on the material as well. Unless you have a very large shop with lots of wall space, try not to store plywood against a wall so you have to approach it from the side. Only the top sheet will be readily accessible (everything else will have to be moved to get to sheets on the inside) and it is virtually impossible not to lean offcuts and shorts against the pile. Before you know it, the sheet of plywood you need is buried beneath a pile of scrap lumber you don't want to handle. Whenever sheet goods are stored on edge, take care to get them as vertical as possible and rotate unused sheets once in a while. If not, the sheet will take on a bow that will make it tough to build straight cabinets and shelves. One way Jigs and patterns are another kind of material that most shops have plenty of. Furniture-maker Troy Sexton is in good company keeping them on a wall over a bench. ' 20°, each end of tube One screw at the bottom of each tube attaches it to the plywood base Each row of tubes is cut to be 1V2" longer than the row above This storage bin is made from sections of 4" PVC posts. Its graduated rows provide lots of inexpensive storage for just about anything a shop produces, including short scraps. Metal strap keeps unit together These metal racks, in the workshop of Tom Willenborg, hold a lot of plywood. Storing panel goods on edge, as Willenborg does in the rack in the foreground, saves floor space and makes access relatively easy. popularwoodworking.com I 35 |