Popular Woodworking 2007-06 № 162, страница 66

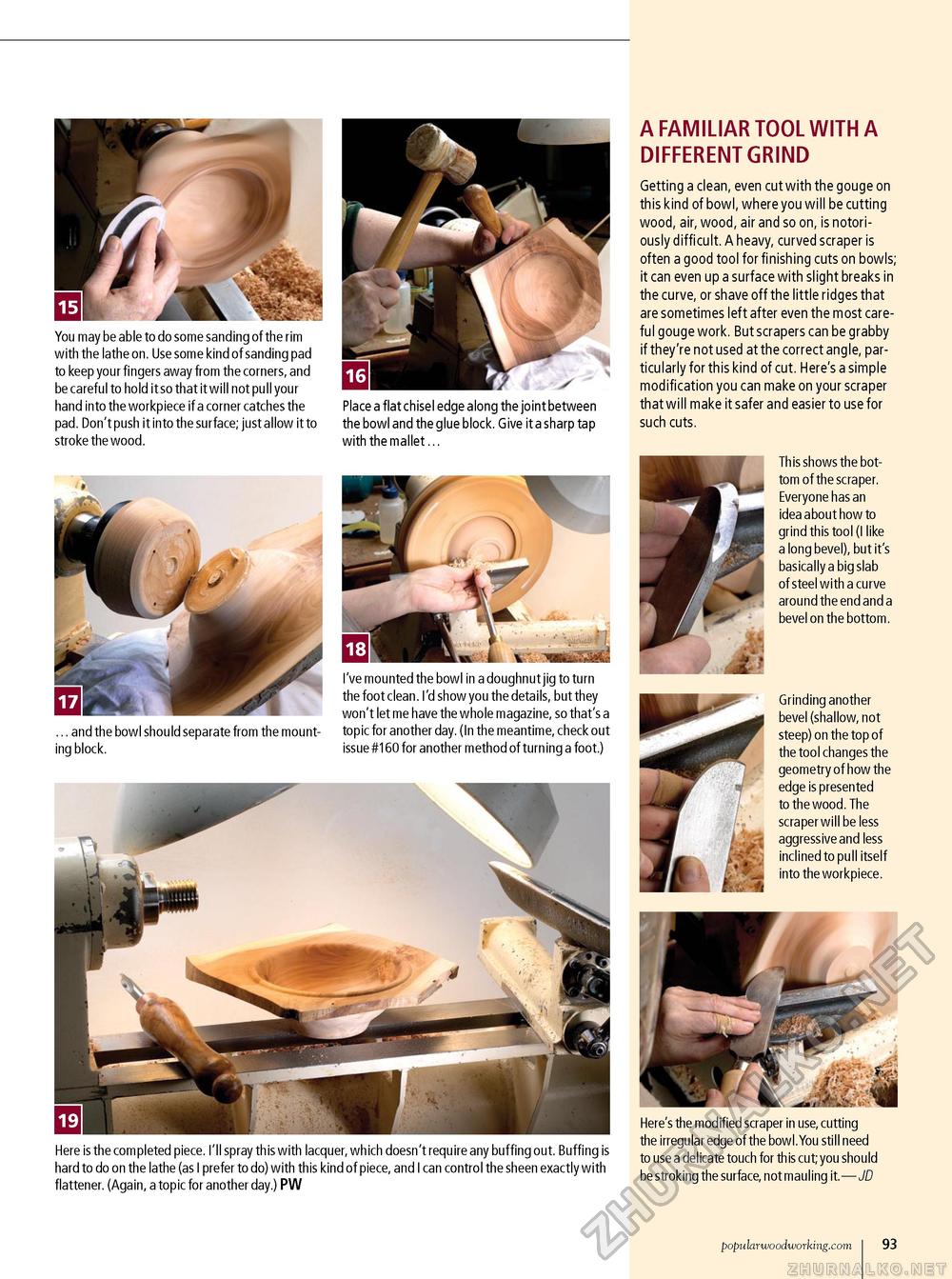

You may be able to do some sanding of the rim with the lathe on. Use some kind of sanding pad to keep your fingers away from the corners, and be careful to hold it so that it will not pull your hand into the workpiece if a corner catches the pad. Don't push it into the surface; just allow it to stroke the wood. t ... and the bowl should separate from the mounting block. Place a flat chisel edge along the joint between the bowl and the glue block. Give it a sharp tap with the mallet ... I've mounted the bowl in a doughnut jig to turn the foot clean. I'd show you the details, but they won't let me have the whole magazine, so that's a topic for another day. (In the meantime, check out issue #160 for another method of turning a foot.) A FAMILIAR TOOL WITH A DIFFERENT GRIND Getting a clean, even cut with the gouge on this kind of bowl, where you will be cutting wood, air, wood, air and so on, is notoriously difficult. A heavy, curved scraper is often a good tool for finishing cuts on bowls; it can even up a surface with slight breaks in the curve, or shave off the little ridges that are sometimes left after even the most careful gouge work. But scrapers can be grabby if they're not used at the correct angle, particularly for this kind of cut. Here's a simple modification you can make on your scraper that will make it safer and easier to use for such cuts. This shows the bottom of the scraper. Everyone has an idea about how to grind this tool (I like a long bevel), but it's basically a big slab of steel with a curve around the end and a bevel on the bottom. Grinding another bevel (shallow, not steep) on the top of the tool changes the geometry of how the edge is presented to the wood. The scraper will be less aggressive and less inclined to pull itself into the workpiece. Here's the modified scraper in use, cutting the irregular edge of the bowl. You still need to use a delicate touch for this cut; you should be stroking the surface, not mauling it.—JD Here is the completed piece. I'll spray this with lacquer, which doesn't require any buffing out. Buffing is hard to do on the lathe (as I prefer to do) with this kind of piece, and I can control the sheen exactly with flattener. (Again, a topic for another day.) PW popularwoodworking.com 23 |