Popular Woodworking 2007-10 № 164, страница 27

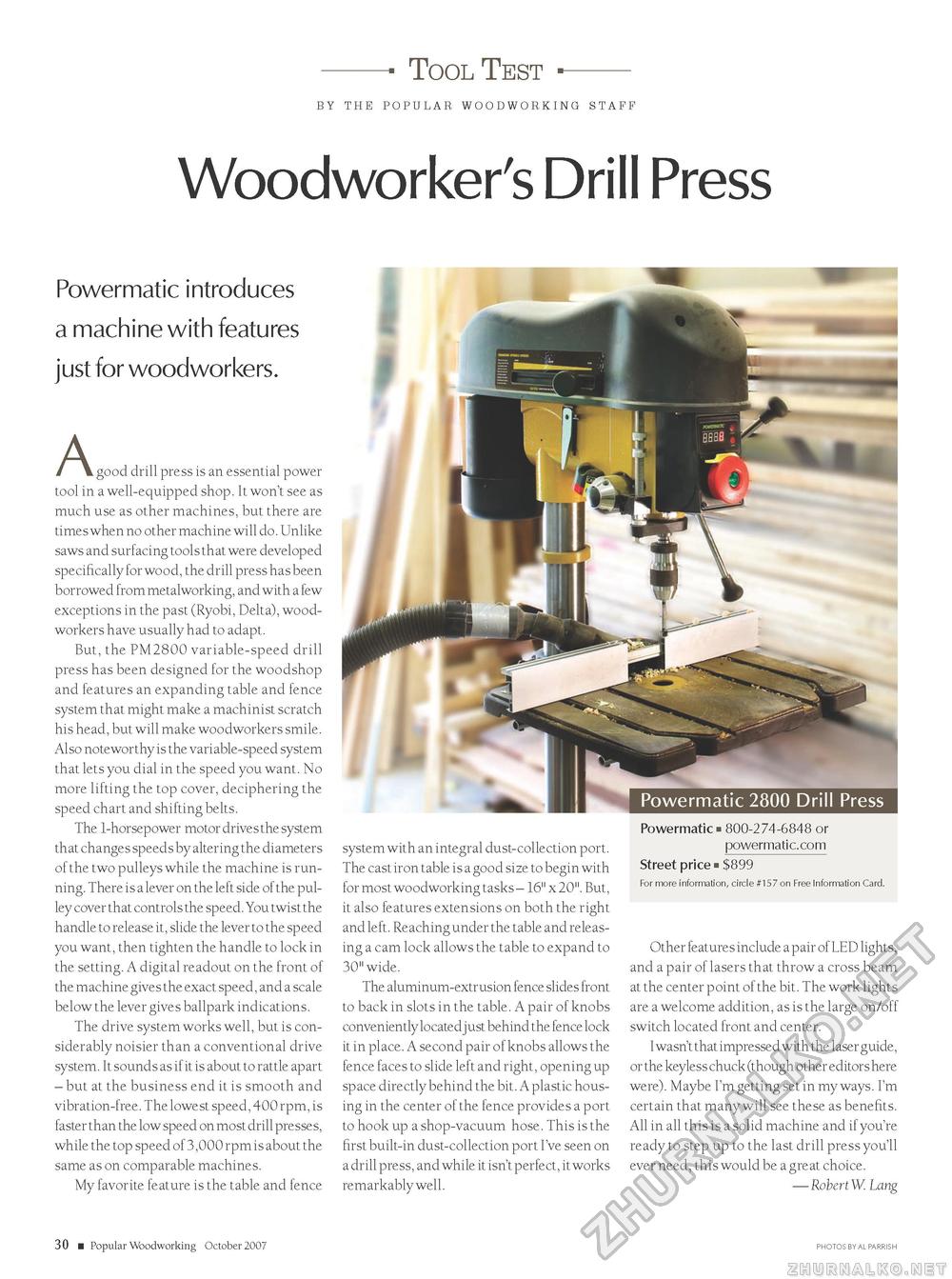

Tool Testby the popular woodworking staff Woodworker's Drill PressPowermatic introduces a machine with features just for woodworkers. A l \ good drill press is an essential power tool in a well-equipped shop. It won't see as much use as other machines, but there are times when no other machine will do. Unlike saws and surfacing tools that were developed specifically for wood, the drill press has been borrowed from metalworking, and with a few exceptions in the past (Ryobi, Delta), woodworkers have usually had to adapt. But, the PM2800 variable-speed drill press has been designed for the woodshop and features an expanding table and fence system that might make a machinist scratch his head, but will make woodworkers smile. Also noteworthy is the variable-speed system that lets you dial in the speed you want. No more lifting the top cover, deciphering the speed chart and shifting belts. The 1-horsepower motor drives the system that changes speeds by altering the diameters of the two pulleys while the machine is running. There is a lever on the left side of the pulley cover that controls the speed. You twist the handle to release it, slide the lever to the speed you want, then tighten the handle to lock in the setting. A digital readout on the front of the machine gives the exact speed, and a scale below the lever gives ballpark indications. The drive system works well, but is considerably noisier than a conventional drive system. It sounds as if it is about to rattle apart - but at the business end it is smooth and vibration-free. The lowest speed, 400 rpm, is faster than the low speed on most drill presses, while the top speed of3,000 rpm is about the same as on comparable machines. My favorite feature is the table and fence system with an integral dust-collection port. The cast iron table is a good size to begin with for most woodworking tasks - 16" x 20". But, it also features extensions on both the right and left. Reaching under the table and releasing a cam lock allows the table to expand to 30" wide. The aluminum-extrusion fence slides front to back in slots in the table. A pair of knobs conveniently locatedjust behind the fence lock it in place. A second pair of knobs allows the fence faces to slide left and right, opening up space directly behind the bit. A plastic housing in the center of the fence provides a port to hook up a shop-vacuum hose. This is the first built-in dust-collection port I've seen on a drill press, and while it isn't perfect, it works remarkably well. Powermatic ■ 800-274-6848 or powermatic.com Street price ■ $899 For more information, circle #157 on Free Information Card. Other features include a pair of LED lights, and a pair of lasers that throw a cross beam at the center point of the bit. The work lights are a welcome addition, as is the large on/off switch located front and center. I wasn't that impressed with the laser guide, or the keyless chuck (though other editors here were). Maybe I'm getting set in my ways. I'm certain that many will see these as benefits. All in all this is a solid machine and if you're ready to step up to the last drill press you'll ever need, this would be a great choice. — Robert W. Lang 30 ■ Popular Woodworking October 2007 photos by al parrish |