Popular Woodworking 2007-11 № 165, страница 24

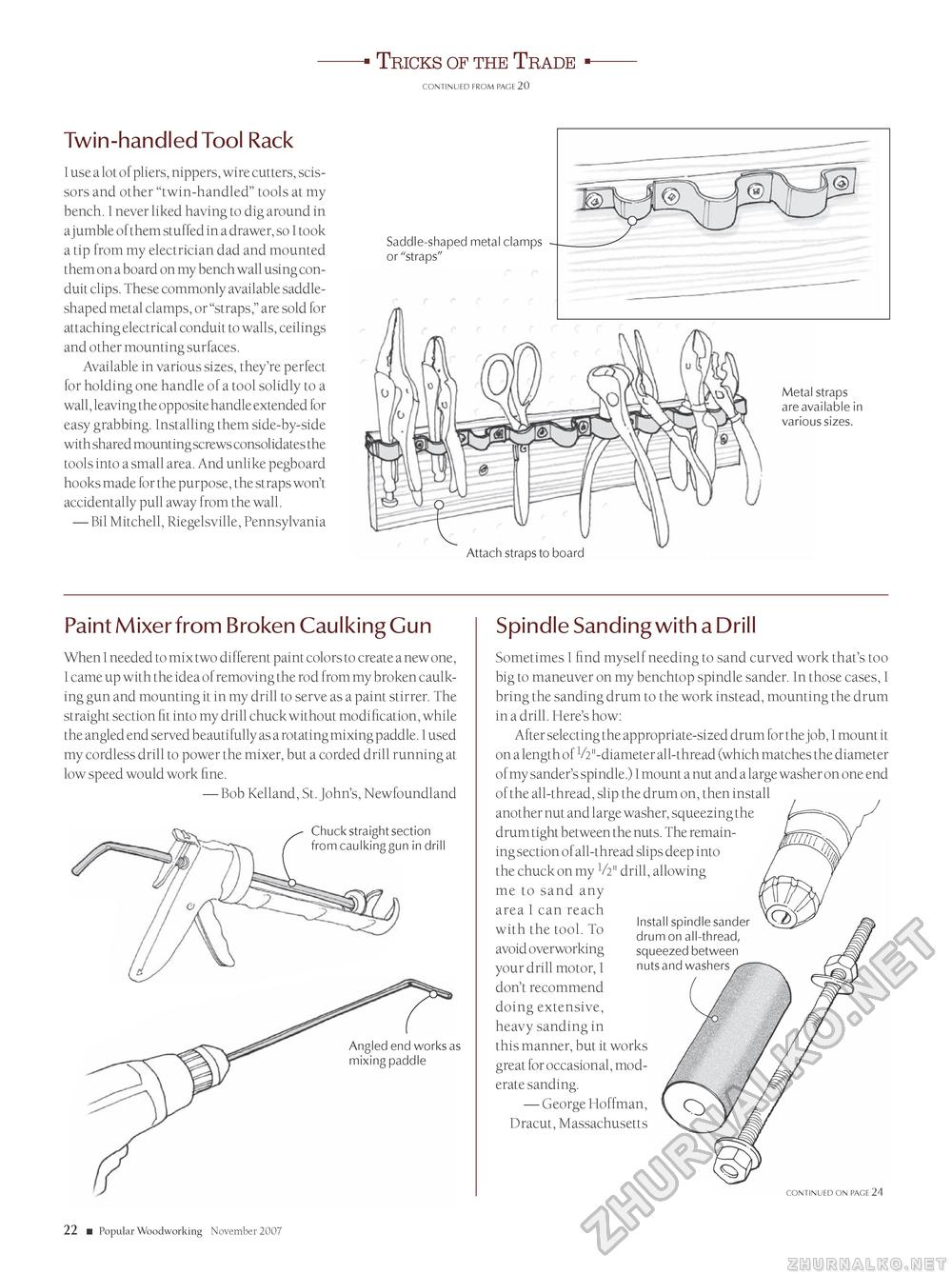

Tricks of the Trade CONTINUED FROM PAGE 20 Twin-handled Tool Rack I use a lot of pliers, nippers, wire cutters, scissors and other "twin-handled" tools at my bench. I never liked having to dig around in a jumble of them stuffed in a drawer, so I took a tip from my electrician dad and mounted them on a board on my bench wall using conduit clips. These commonly available saddle-shaped metal clamps, or "straps," are sold for attaching electrical conduit to walls, ceilings and other mounting surfaces. Available in various sizes, they're perfect for holding one handle of a tool solidly to a wall, leaving the opposite handle extended for easy grabbing. Installing them side-by-side with shared mounting screws consolidates the tools into a small area. And unlike pegboard hooks made for the purpose, the straps won't accidentally pull away from the wall. — Bil Mitchell, Riegelsville, Pennsylvania Saddle-shaped metal clamps or "straps" Metal straps are available in Attach straps to board Paint Mixer from Broken Caulking Gun When I needed to mix two different paint colors to create a new one, I came up with the idea of removing the rod from my broken caulking gun and mounting it in my drill to serve as a paint stirrer. The straight section fit into my drill chuck without modification, while the angled end served beautifully as a rotating mixing paddle. I used my cordless drill to power the mixer, but a corded drill running at low speed would work fine. — Bob Kelland, St. John's, Newfoundland Chuck straight section from caulking gun in drill Angled end works as mixing paddle Spindle Sanding with a Drill Sometimes I find myself needing to sand curved work that's too big to maneuver on my benchtop spindle sander. In those cases, I bring the sanding drum to the work instead, mounting the drum in a drill. Here's how: After selecting the appropriate-sized drum for the job, I mount it on a length of V2"-diameter all-thread (which matches the diameter of my sander's spindle.) I mount a nut and a large washer on one end of the all-thread, slip the drum on, then install another nut and large washer, squeezing the drum tight between the nuts. The remaining section of all-thread slips deep into the chuck on my V2" drill, allowing me to sand any area I can reach with the tool. To avoid overworking your drill motor, I don't recommend doing extensive, heavy sanding in this manner, but it works great for occasional, moderate sanding. — George Hoffman, Dracut. Massachusetts Install spindle sander drum on all-thread, squeezed between nuts and washers CONTINUED ON PAGE 24 22 ■ Popular Woodworking November 2007 |