Popular Woodworking 2007-11 № 165, страница 55

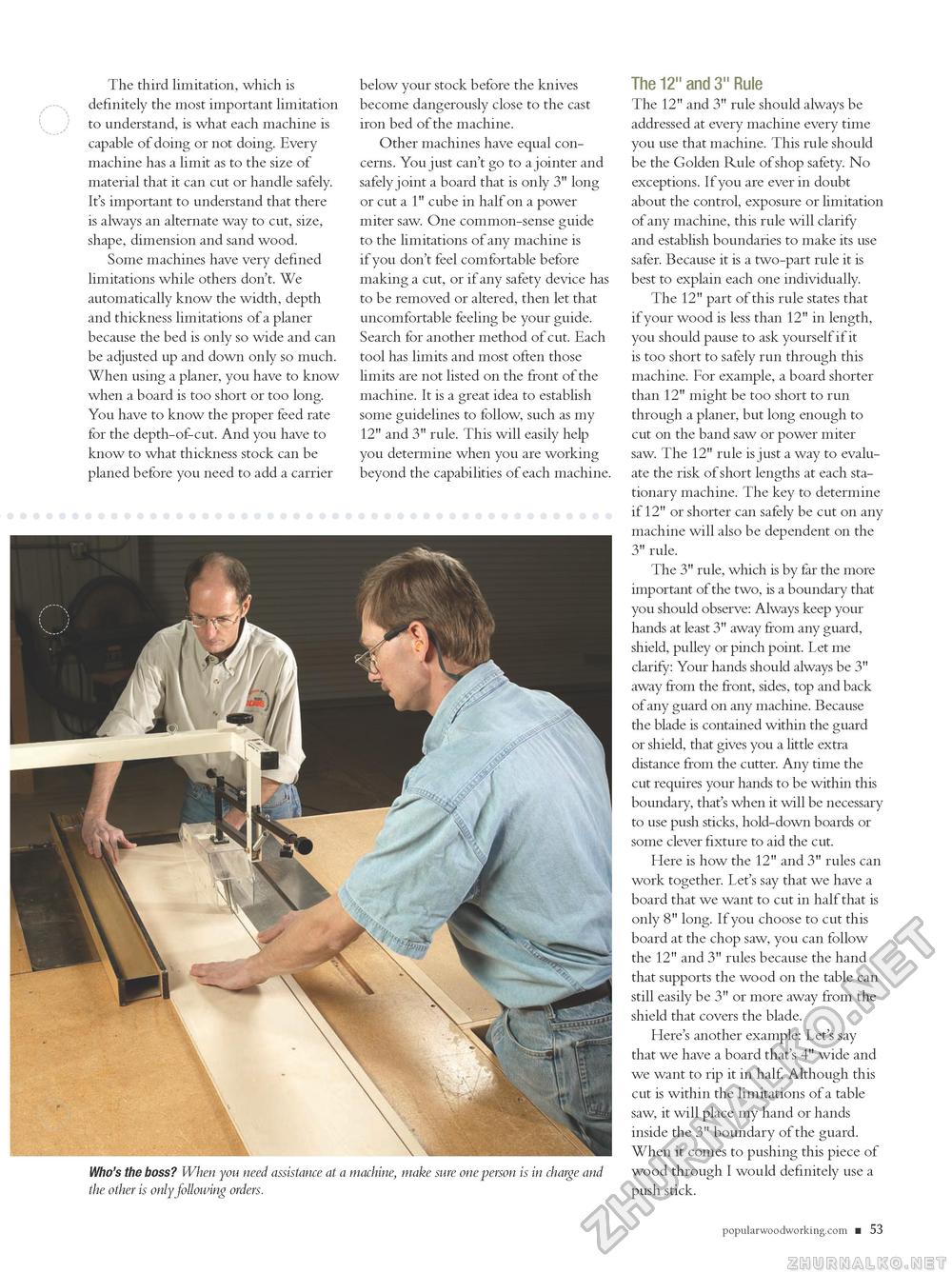

The third limitation, which is definitely the most important limitation to understand, is what each machine is capable of doing or not doing. Every machine has a limit as to the size of material that it can cut or handle safely. It's important to understand that there is always an alternate way to cut, size, shape, dimension and sand wood. Some machines have very defined limitations while others don't. We automatically know the width, depth and thickness limitations of a planer because the bed is only so wide and can be adjusted up and down only so much. When using a planer, you have to know when a board is too short or too long. You have to know the proper feed rate for the depth-of-cut. And you have to know to what thickness stock can be planed before you need to add a carrier below your stock before the knives become dangerously close to the cast iron bed of the machine. Other machines have equal concerns. You just can't go to a jointer and safely joint a board that is only 3" long or cut a 1" cube in half on a power miter saw. One common-sense guide to the limitations of any machine is if you don't feel comfortable before making a cut, or if any safety device has to be removed or altered, then let that uncomfortable feeling be your guide. Search for another method of cut. Each tool has limits and most often those limits are not listed on the front of the machine. It is a great idea to establish some guidelines to follow, such as my 12" and 3" rule. This will easily help you determine when you are working beyond the capabilities of each machine. Who's the boss? When you need assistance at a machine, make sure one person is in charge and the other is only following orders. The 12" and 3" Rule The 12" and 3" rule should always be addressed at every machine every time you use that machine. This rule should be the Golden Rule of shop safety. No exceptions. If you are ever in doubt about the control, exposure or limitation of any machine, this rule will clarify and establish boundaries to make its use safer. Because it is a two-part rule it is best to explain each one individually. The 12" part of this rule states that if your wood is less than 12" in length, you should pause to ask yourself if it is too short to safely run through this machine. For example, a board shorter than 12" might be too short to run through a planer, but long enough to cut on the band saw or power miter saw. The 12" rule is just a way to evaluate the risk of short lengths at each stationary machine. The key to determine if 12" or shorter can safely be cut on any machine will also be dependent on the 3" rule. The 3" rule, which is by far the more important of the two, is a boundary that you should observe: Always keep your hands at least 3" away from any guard, shield, pulley or pinch point. Let me clarify: Your hands should always be 3" away from the front, sides, top and back of any guard on any machine. Because the blade is contained within the guard or shield, that gives you a little extra distance from the cutter. Any time the cut requires your hands to be within this boundary, that's when it will be necessary to use push sticks, hold-down boards or some clever fixture to aid the cut. Here is how the 12" and 3" rules can work together. Let's say that we have a board that we want to cut in half that is only 8" long. If you choose to cut this board at the chop saw, you can follow the 12" and 3" rules because the hand that supports the wood on the table can still easily be 3" or more away from the shield that covers the blade. Here's another example: Let's say that we have a board that's 4" wide and we want to rip it in half. Although this cut is within the limitations of a table saw, it will place my hand or hands inside the 3" boundary of the guard. When it comes to pushing this piece of wood through I would definitely use a push stick. popularwoodworking.com ■ 53 |