Popular Woodworking 2007-11 № 165, страница 60

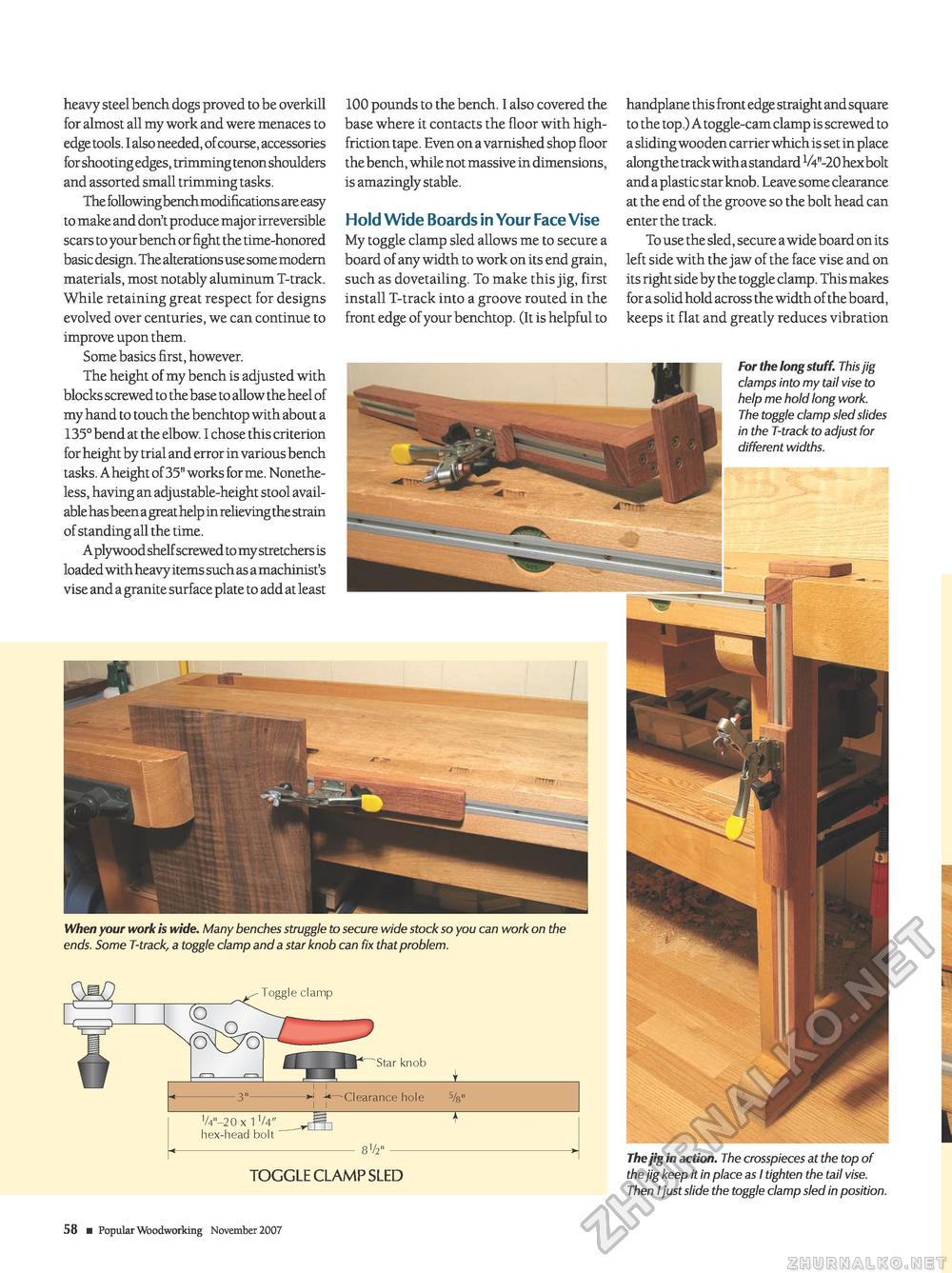

heavy steel bench dogs proved to be overkill for almost all my work and were menaces to edge tools. I also needed, of course, accessories for shooting edges, trimming tenon shoulders and assorted small trimming tasks. The followingbenchmodifications are easy to make and don't produce major irreversible scars to your bench or fight the time-honored basic design. The alterations use some modern materials, most notably aluminum T-track. While retaining great respect for designs evolved over centuries, we can continue to improve upon them. Some basics first, however. The height of my bench is adjusted with blocks screwed to the base to allow the heel of my hand to touch the benchtop with about a 135° bend at the elbow. I chose this criterion for height by trial and error in various bench tasks. A height of 35" works for me. Nonetheless, having an adjustable-height stool available has been a greathelp in relieving the strain of standing all the time. A plywood shelf screwed to my stretchers is loaded with heavy items such as a machinist's vise and a granite surface plate to add at least 100 pounds to the bench. I also covered the base where it contacts the floor with high-friction tape. Even on a varnished shop floor the bench, while not massive in dimensions, is amazingly stable. Hold Wide Boards in Your Face Vise My toggle clamp sled allows me to secure a board of any width to work on its end grain, such as dovetailing. To make this jig, first install T-track into a groove routed in the front edge of your benchtop. (It is helpful to handplane this front edge straight and square to the top.) A toggle-cam clamp is screwed to a sliding wooden carrier which is set in place along the track with a standard 1/4"-20 hex bolt and a plastic star knob. Leave some clearance at the end of the groove so the bolt head can enter the track. To use the sled, secure a wide board on its left side with the j aw of the face vise and on its right side by the toggle clamp. This makes for a solid hold across the width of the board, keeps it flat and greatly reduces vibration For the long stuff. This jig clamps into my tail vise to help me hold long work. The toggle clamp sled slides in the T-track to adjust for different widths. TOGGLE CLAMP SLED The jig in action. The crosspieces at the top of the jig keep it in place as I tighten the tail vise. Then I just slide the toggle clamp sled in position. 58 ■ Popular Woodworking November 2007 |