Popular Woodworking 2007-11 № 165, страница 61

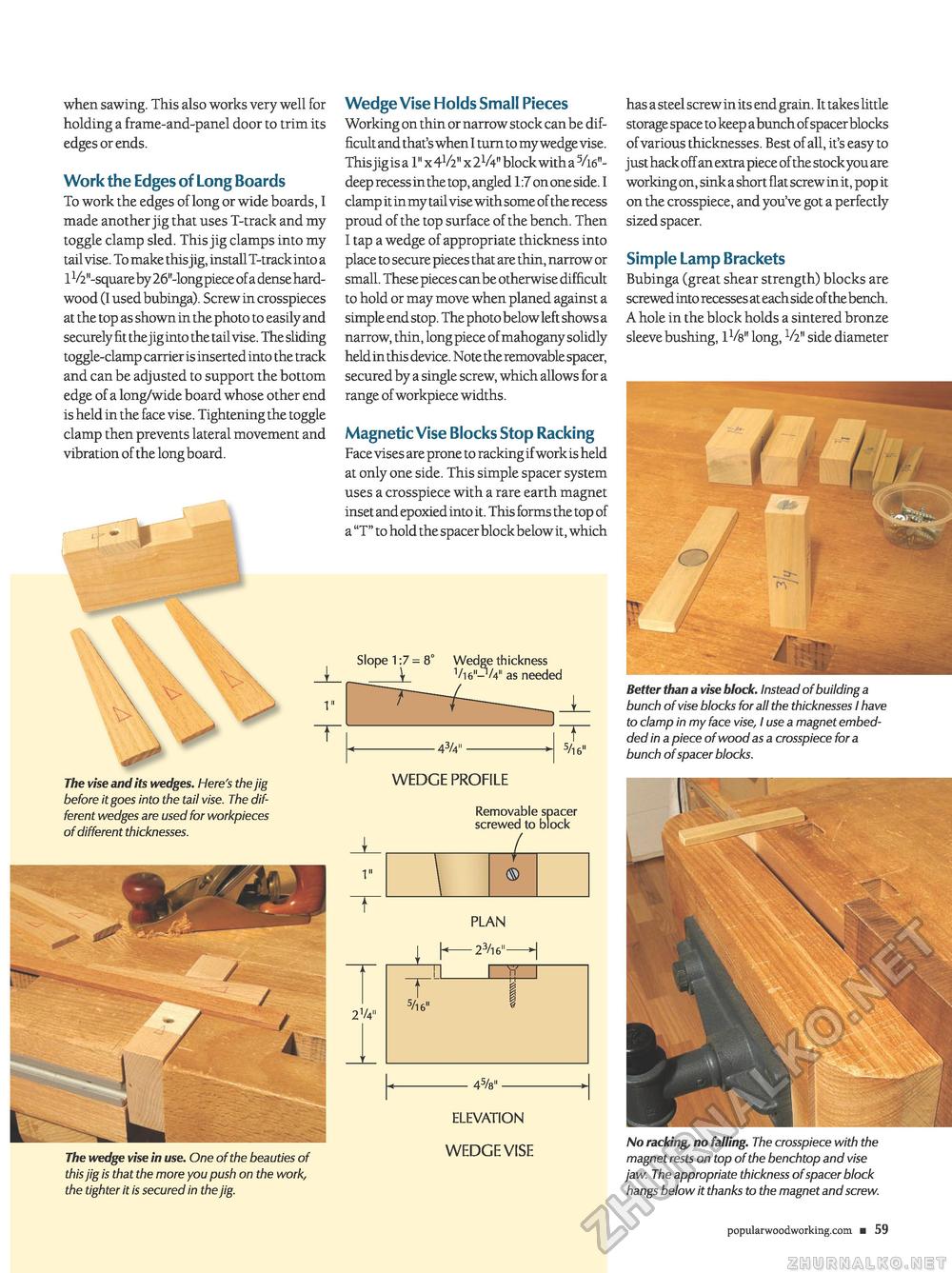

when sawing. This also works very well for holding a frame-and-panel door to trim its edges or ends. Work the Edges of Long Boards To work the edges of long or wide boards, I made another jig that uses T-track and my toggle clamp sled. This jig clamps into my tail vise. To make this jig, install T-track into a 1 ^"-square by 26"-long piece of a dense hardwood (I used bubinga). Screw in crosspieces at the top as shown in the photo to easily and securely fit the jig into the tail vise. The sliding toggle-clamp carrier is inserted into the track and can be adjusted to support the bottom edge of a long/wide board whose other end is held in the face vise. Tightening the toggle clamp then prevents lateral movement and vibration of the long board. Wedge Vise Holds Small Pieces Working on thin or narrow stock can be difficult and that's when I turn to my wedge vise. This jig is a 1" x 4V2" x 2V4" block with a Vi6"-deep recess in the top, angled 1:7 on one side. I clamp it in my tail vise with some of the recess proud of the top surface of the bench. Then I tap a wedge of appropriate thickness into place to secure pieces that are thin, narrow or small. These pieces can be otherwise difficult to hold or may move when planed against a simple end stop. The photo below left shows a narrow, thin, long piece of mahogany solidly held in this device. Note the removable spacer, secured by a single screw, which allows for a range of workpiece widths. Magnetic Vise Blocks Stop Racking Face vises are prone to racking if work is held at only one side. This simple spacer system uses a crosspiece with a rare earth magnet inset and epoxied into it. This forms the top of a "T" to hold the spacer block below it, which has a steel screw in its end grain. It takes little storage space to keep a bunch of spacer blocks of various thicknesses. Best of all, it's easy to just hack off an extra piece of the stock you are working on, sink a short flat screw in it, pop it on the crosspiece, and you've got a perfectly sized spacer. Simple Lamp Brackets Bubinga (great shear strength) blocks are screwed into recesses at each side of the bench. A hole in the block holds a sintered bronze sleeve bushing, lVb" long, V2'1 side diameter No racking, no falling. The crosspiece with the magnet rests on top of the benchtop and vise jaw. The appropriate thickness of spacer block hangs below it thanks to the magnet and screw. popularwoodworking.com ■ 59 Better than a vise block. Instead of building a bunch of vise blocks for all the thicknesses I have to clamp in my face vise, I use a magnet embedded in a piece of wood as a crosspiece for a bunch of spacer blocks. The vise and its wedges. Here's the jig before it goes into the tail vise. The different wedges are used for workpieces of different thicknesses. WEDGE PROFILE Removable spacer screwed to block PLAN -23/16m- ELEVATION WEDGE VISE The wedge vise in use. One of the beauties of this jig is that the more you push on the work, the tighter it is secured in the jig. Slope 1:7= 8° \ Wedge thickness Vi6"-V4" as needed |